Collapsible container

a container and collapsible technology, applied in the field of folding containers, can solve the problem that pockets require a longer pull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

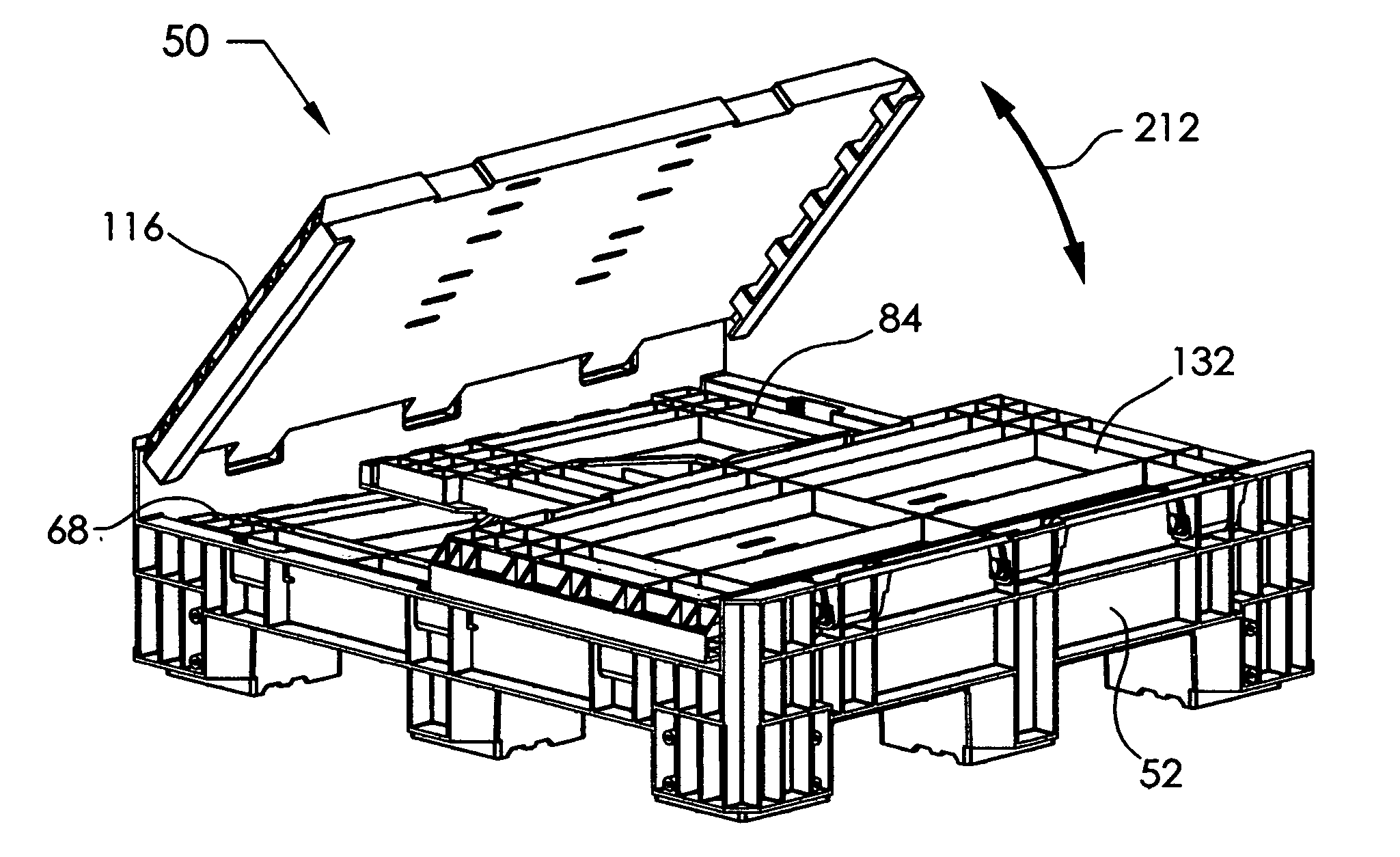

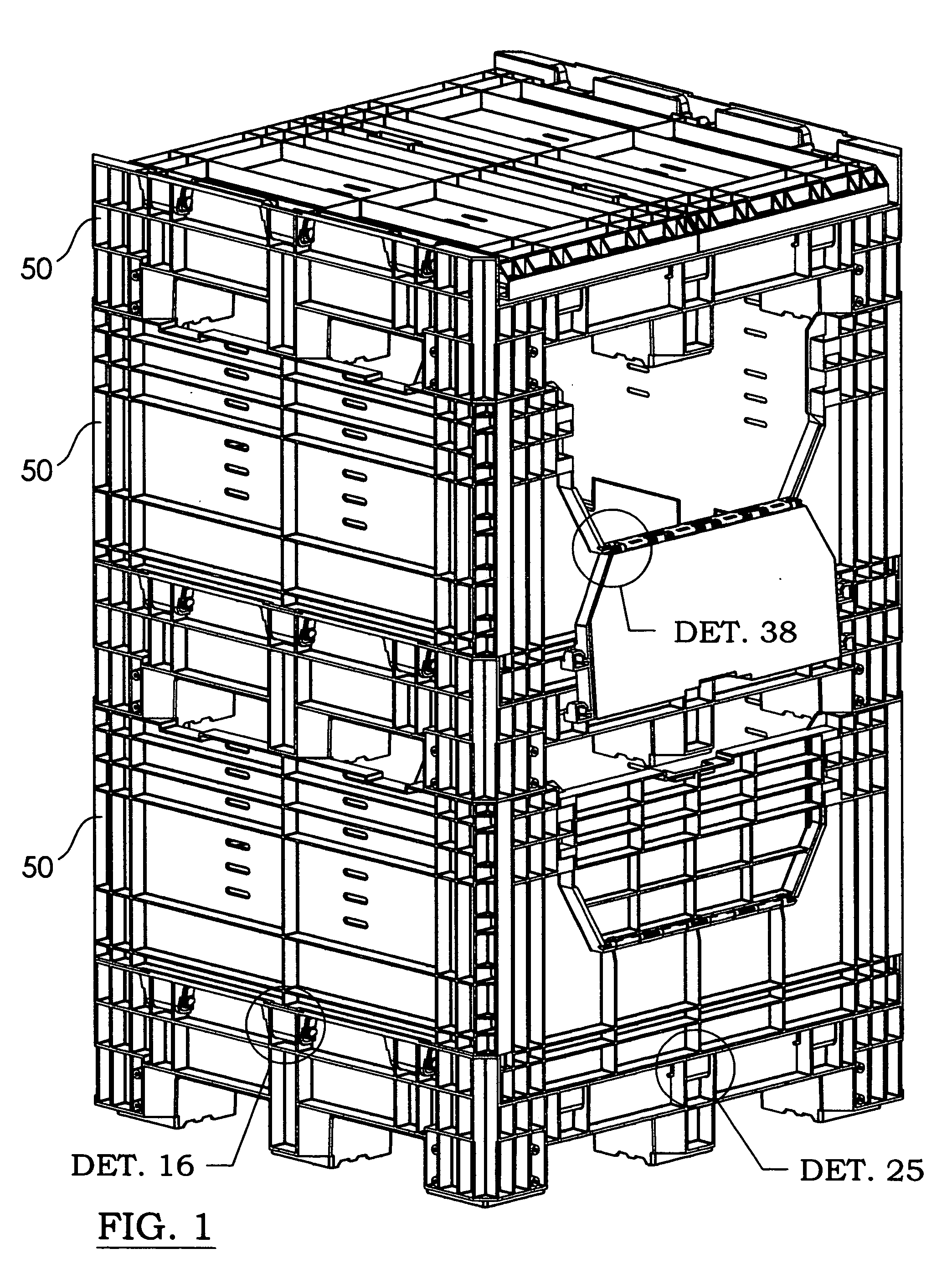

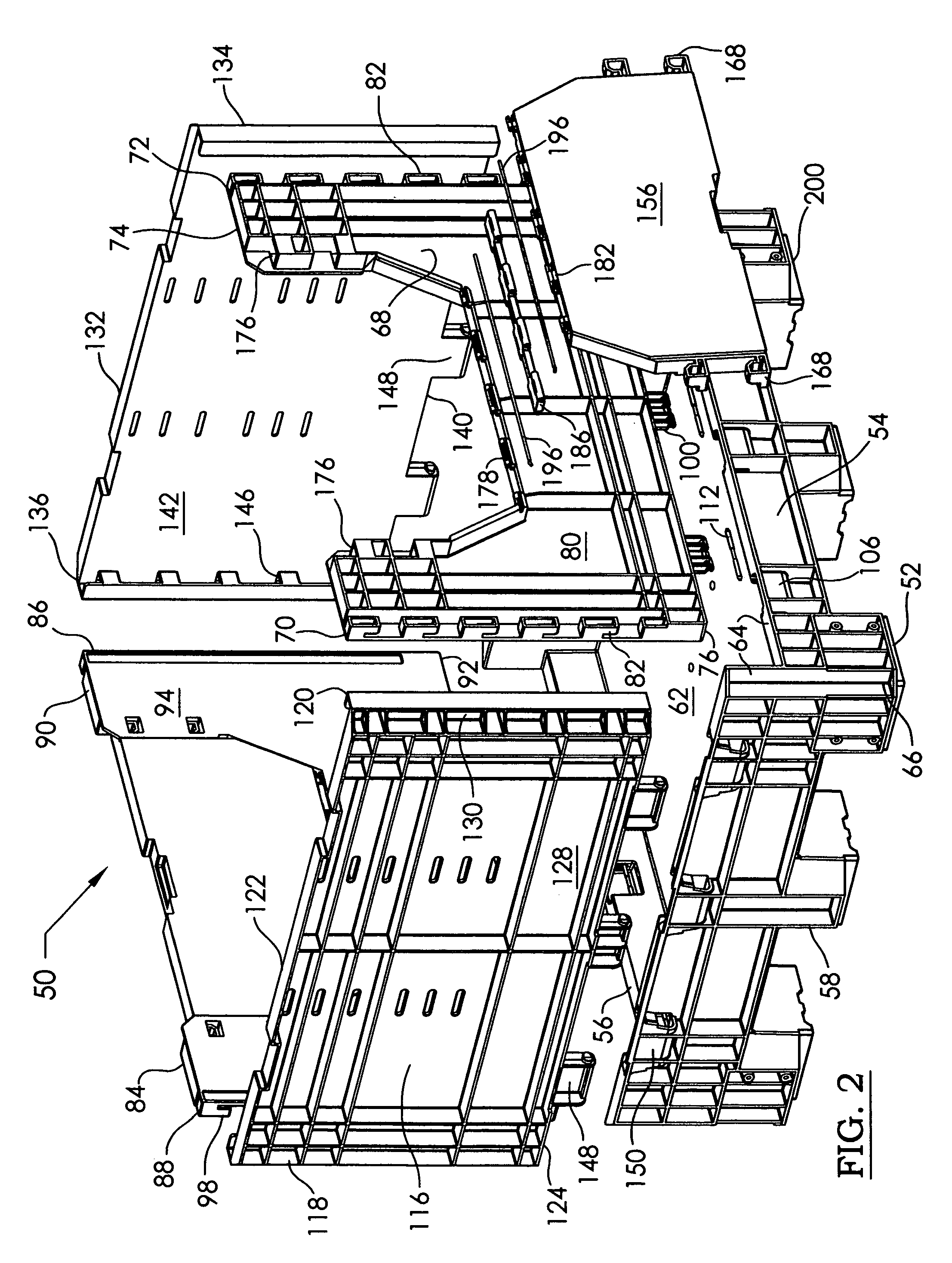

[0076]Referring now to the drawing, and especially to FIGS. 1-32 thereof, a collapsible container is shown at 50, and is for use in conveying and storing bulk material and products. A base 52 extends between opposite front 54 and rear 56 ends, and between opposite left 58 and right 60 sides. The base 52 has a floor 62 extending between the base front 54 and rear 56 ends and between the base left 58 and right 60 sides. The base 52 has a wall 64 extending along the front 54 and rear 56 ends and the left 58 and right 60 sides. The wall 64 projects upward above the floor 62. The base 52 has four corners 66 where the ends meet the sides. FIG. 3 is a top plan view of the base, showing the floor 62 being continuous, with no large openings to trap bulk material, and only a few small drain holes 63. FIG. 6 is a bottom view of FIG. 3, showing the reinforcing structure.

[0077]A front panel 68 extends between opposite first 70 and second 72 edges and between opposite top 74 and bottom 76 edges. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com