Grip sleeve for sports gear

a technology for grip sleeves and sports gear, applied in the field of grip sleeves, can solve the problems of curved outwards, and affecting the use of grip sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

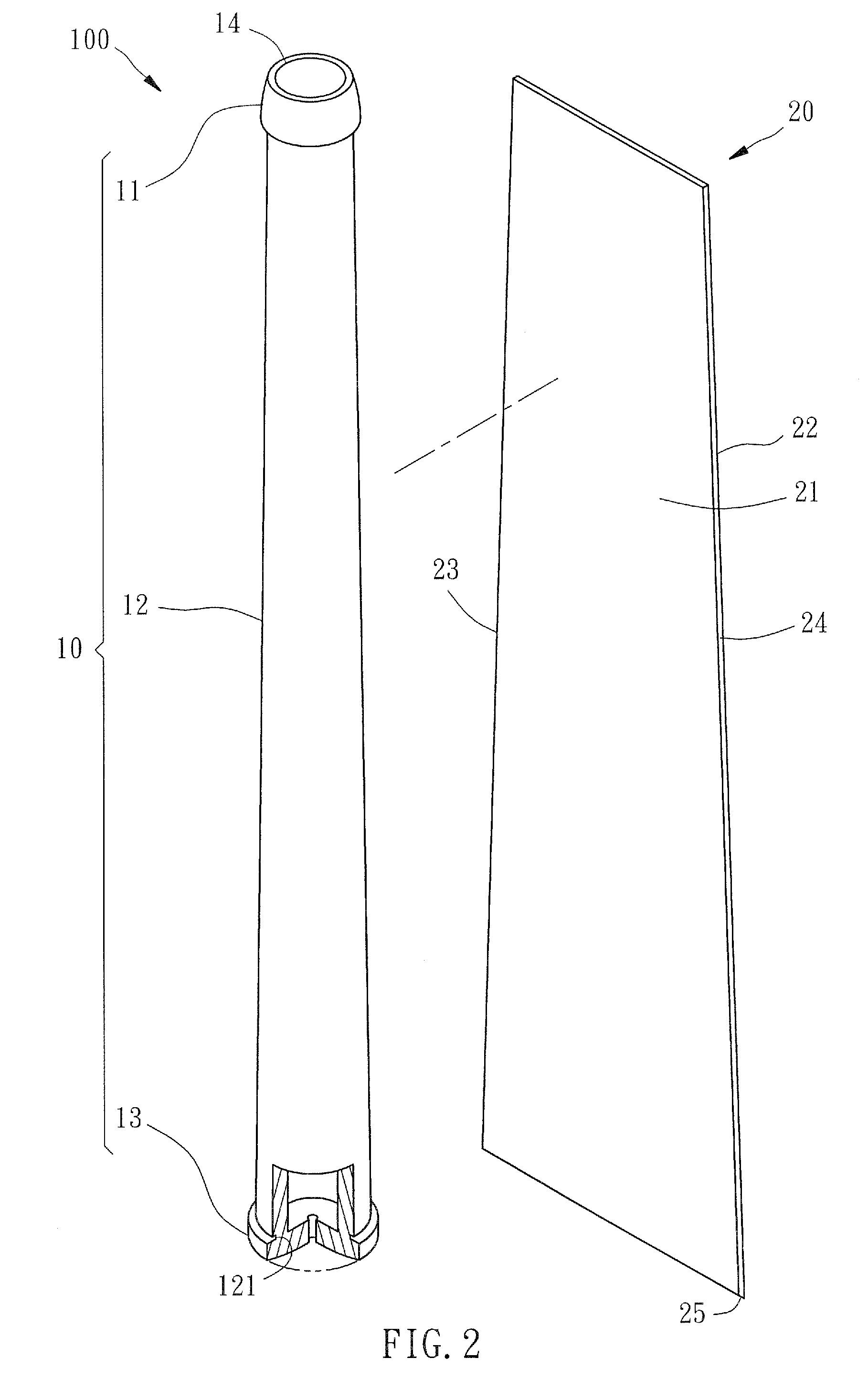

[0017]As shown in FIGS. 2-4, a grip sleeve 100 in accordance with a first preferred embodiment of the present invention comprises a sleeve member 10 and a flexible wrapping member 20.

[0018]The sleeve member 10 is molded from rubber, having a head 11, a body 12, and a heel 13. The body 12 is integrally connected between the head 11 and the heel 13. The head 11 and the heel 13 have an outer diameter greater than the outer diameter of the body 12 by about 1.6-2.0 mm, preferably 1.8 mm. The sleeve member 10 has an axial hole 14 extending through the head 11, the body 12 and the heel 13 for receiving a sports gear shaft (not shown). The body 12 has a radially-recessed annular locating groove 121 extending around the periphery and abutted with the heal 13. The annular locating groove 121 has a radial depth about 1.2-0.5 mm, and axial width about 0.6-1.0 mm, smaller than the thickness of the flexible wrapping member 20. According to this embodiment, the radial depth of the annular locating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com