Magnetic encoder having a stable output property with unsaturated magnetic sensor

a technology of unsaturated magnetic sensors and encoders, applied in the field of magnetic encoders, can solve the problems of unintentional output setoff, reducing resolution by half, and achieving sufficient output, and achieve stable output, high resolution, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

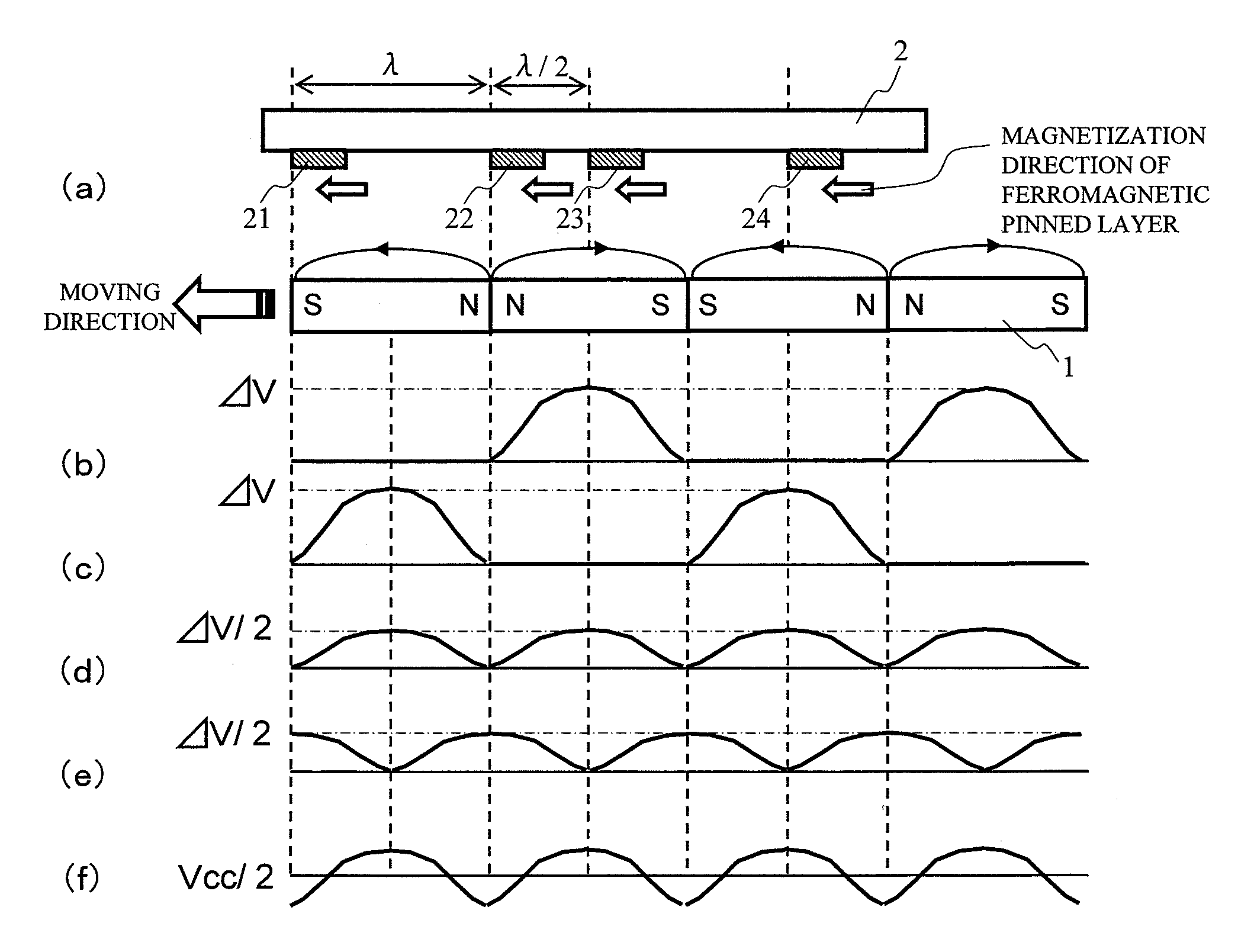

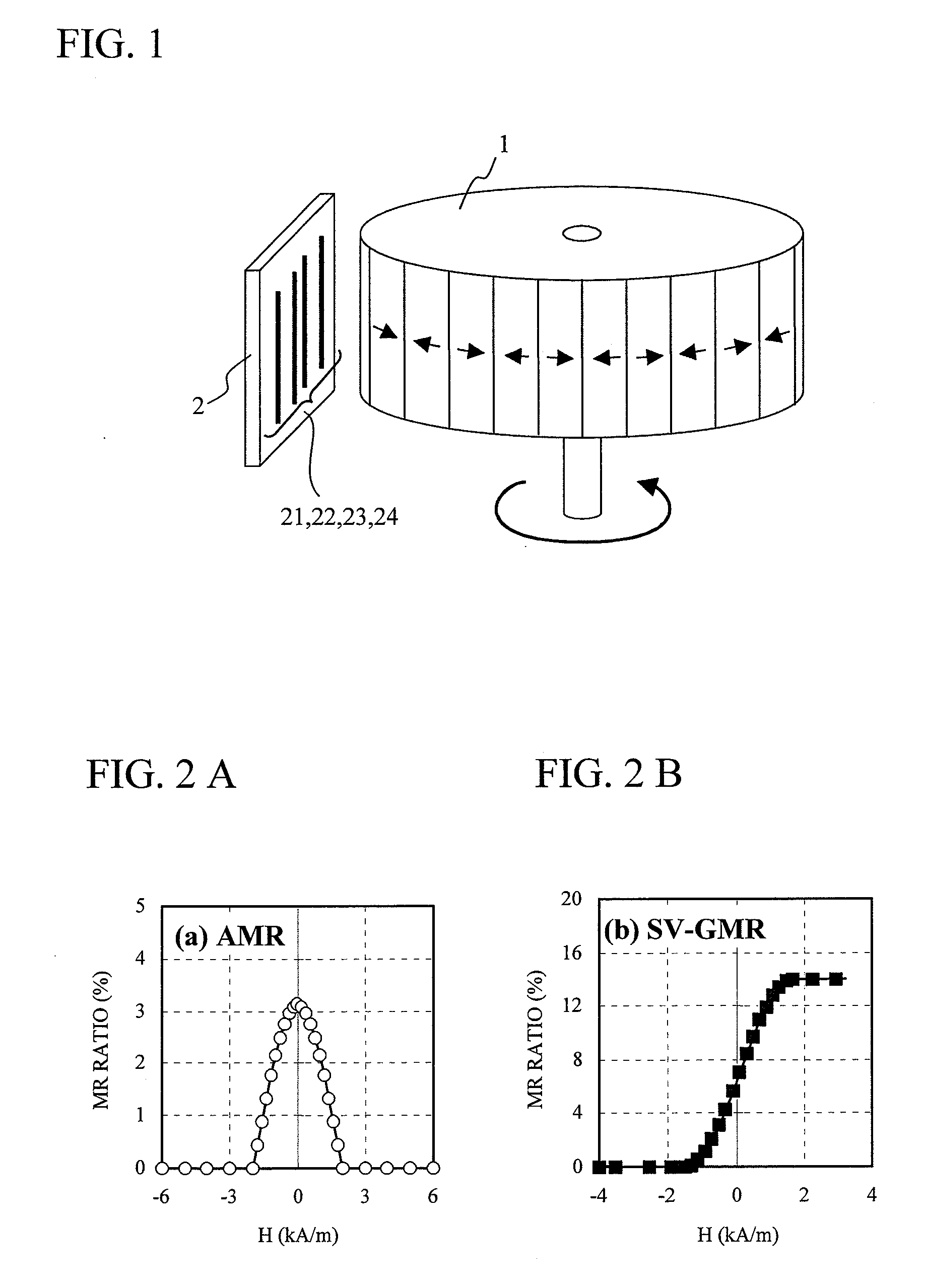

[0046]FIG. 1 illustrates, in schematic form, the configuration of a magnetic encoder according to the present invention. The magnetic encoder includes a magnetic medium 1, and a magnetic sensor 2 that moves relative to the magnetic medium 1, facing the magnetic medium 1 with a predetermined gap in between, and the magnetic medium 1 is magnetized in alternating multipolar form in the direction of relative movement thereof with respect to the magnetic sensor 2.

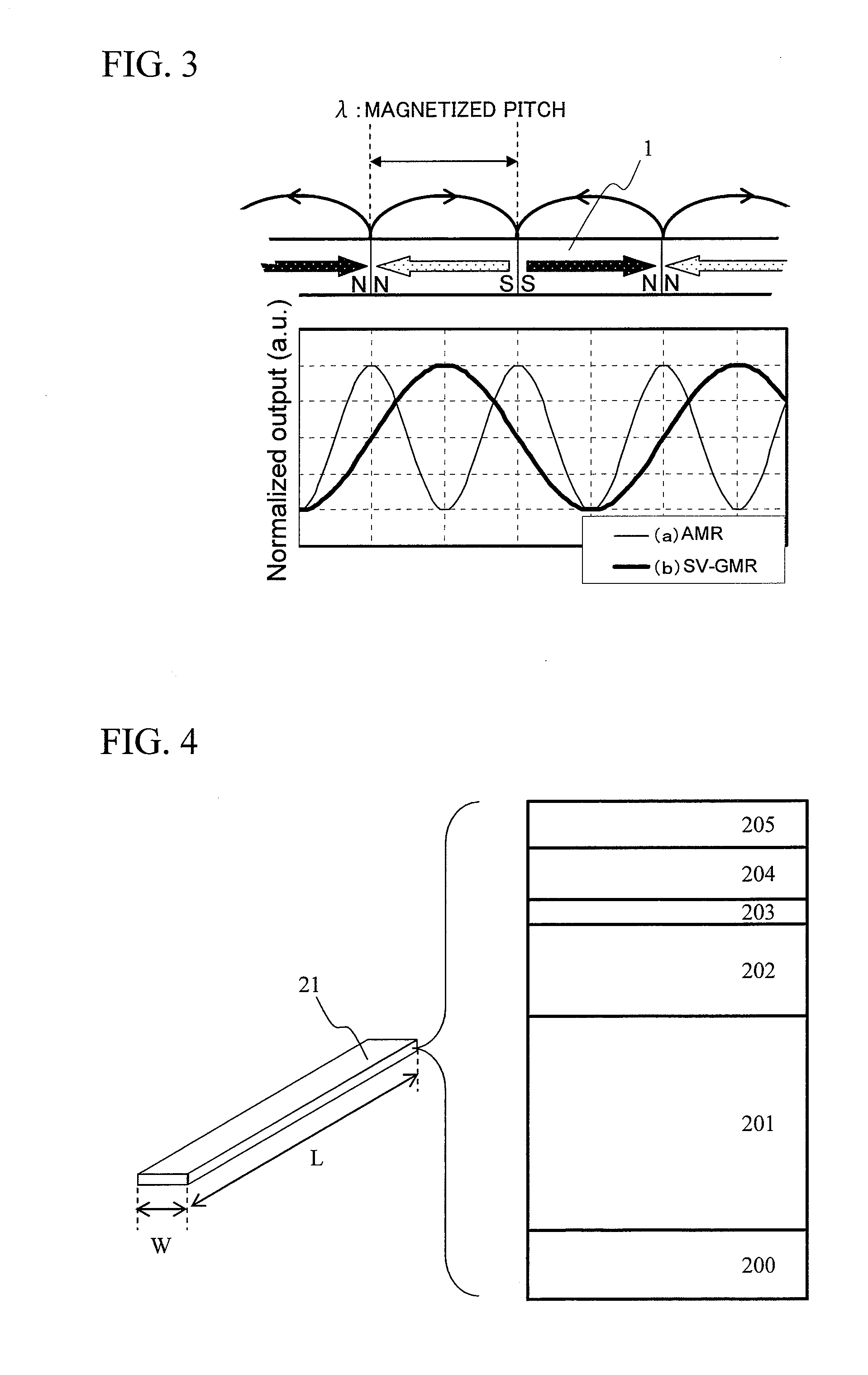

[0047]The magnetic sensor 2 includes a magnetoresistive element 21 using at least a Spin-valve type GMR film. FIG. 4 illustrates, in schematic form, the configuration of the magnetoresistive element 21. The Spin-valve type GMR film that constitutes the magnetoresistive element 21 has a multilayer structure including at least a ferromagnetic pinned layer 202, a non-magnetic intermediate layer 203, and a ferromagnetic free layer 204, which are stacked one on top of another. Furthermore, an antiferromagnetic layer 201 may be formed...

second embodiment

[0077]As previously mentioned, the magnetoresistive element is of such a shape that the pattern length L is very great as compared to the pattern width W. The narrower pattern width W is more favorable in particular for an increase in the resolution for detection of the signal magnetic field from the magnetic medium. However, an increase in an aspect ratio of the pattern length L to the pattern width W results in the shape anisotropy, which causes the induction, into the ferromagnetic free layer, of the uniaxial magnetic anisotropy such that the direction of the pattern length L coincides with the axis of easy magnetization. Thus, the effective Hk* value of the magnetoresistive element becomes larger than the Hk value of the ferromagnetic free layer in itself. This is not desirable because it not only reduces the sensitivity of the magnetoresistive element to the magnetic field but also causes output setoff and hence a decrease in output at the time of superposition of outputs from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com