Sprung support, particularly for a mattress

a spring base and mattress technology, applied in the field of spring base, can solve the problems of production cost differences between the known supportive spring bases, and achieve the effects of avoiding local indentations, avoiding snapping connections, and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

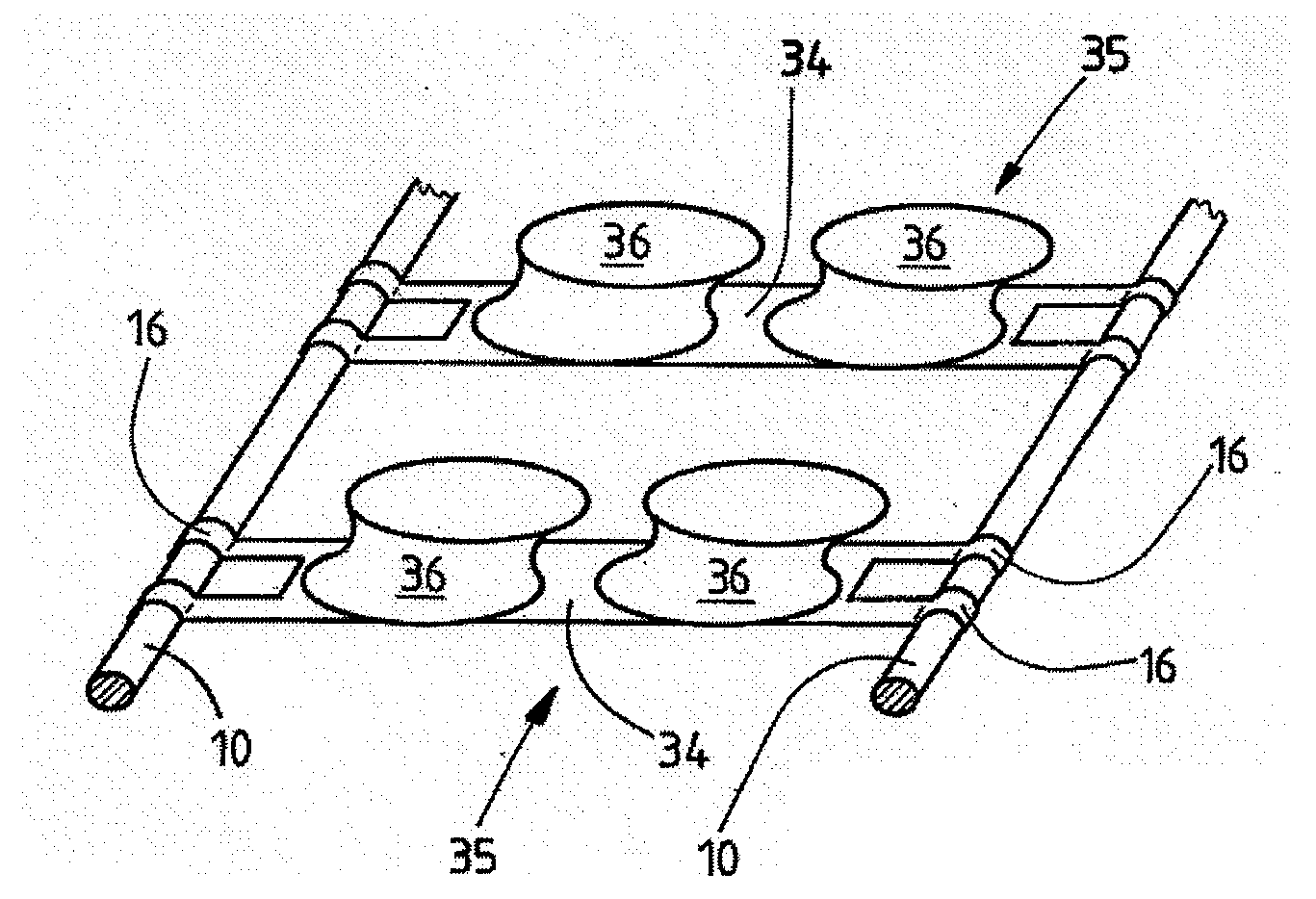

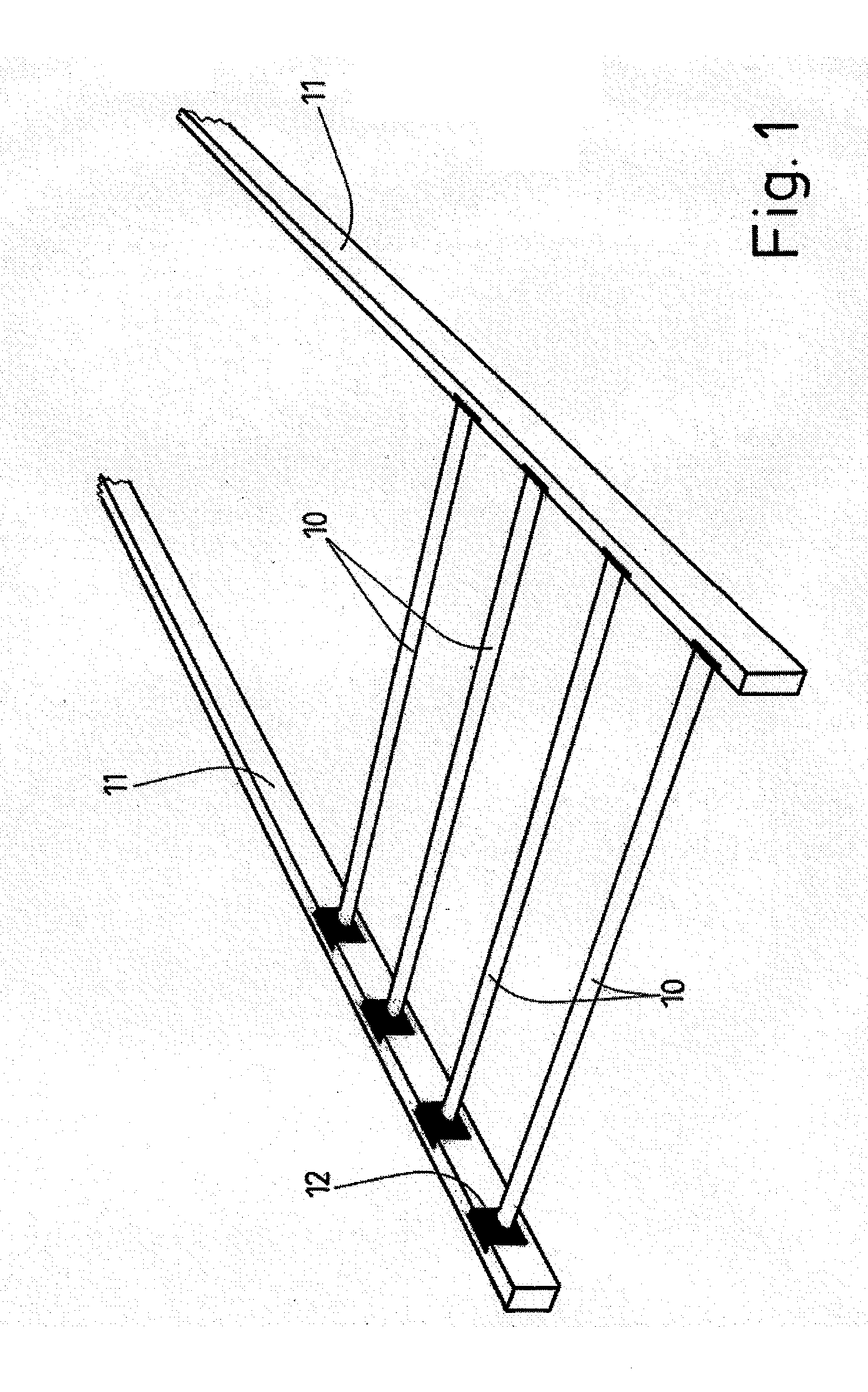

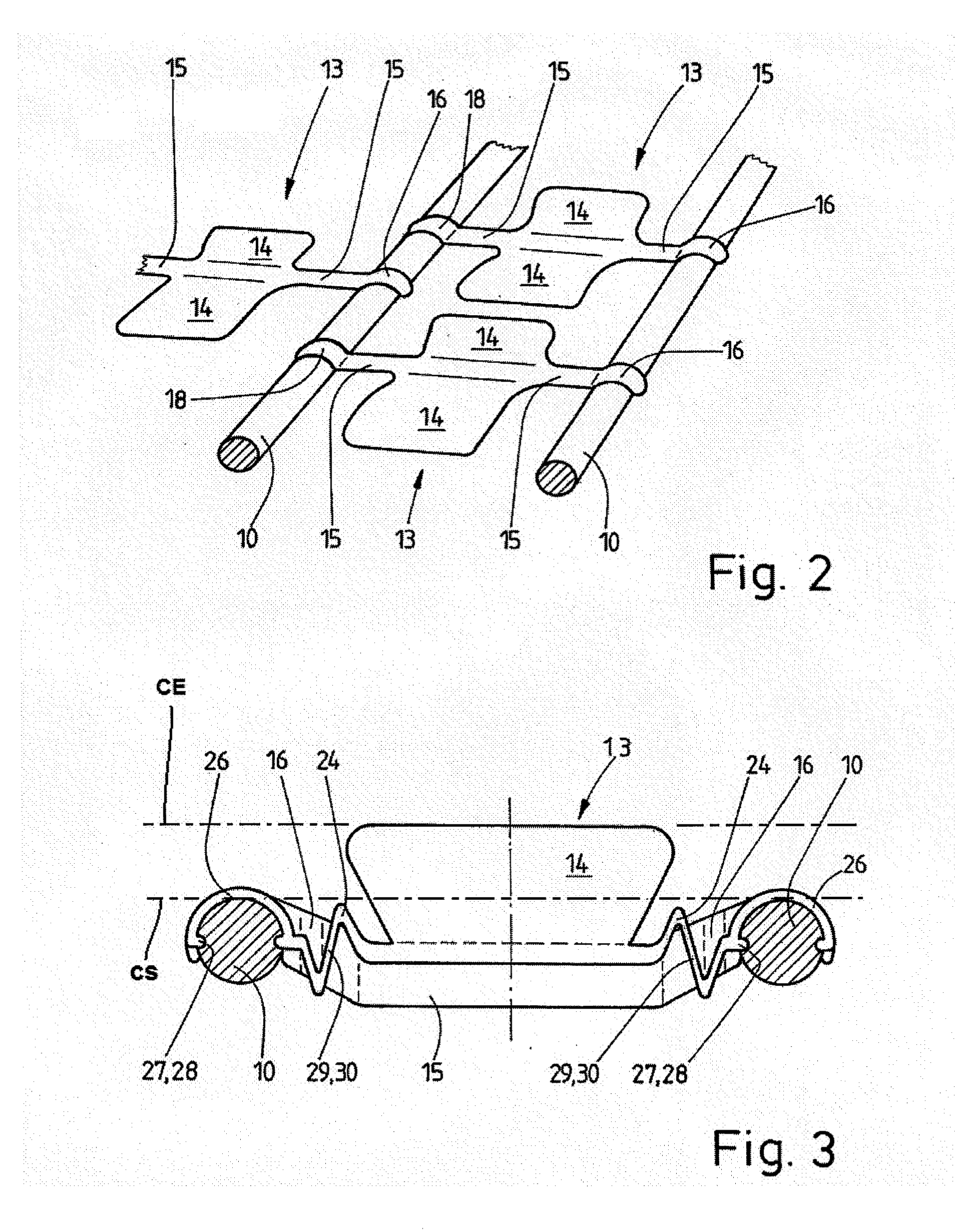

[0034]The supportive spring bases, which are only shown in part in the figures, serve as a support for, for example, a mattress (not shown) of a bed or else of a bunk or a couch.

[0035]The supportive spring base has a plurality of preferably identically designed spring slats 10. The individual spring slats 10 run parallel to one another at a distance. The distances between adjacent spring slats 10 may be identical, but also may differ from one another in some regions. All of the spring slats 10 preferably lie in a common, horizontal plane (shown as broken line CS on FIG. 3), but may also be in a different plane or on a slope in some regions, for example in the head region.

[0036]The spring slats 10 are mounted at opposite ends on two parallel longitudinal struts 11. The longitudinal struts 11 extend in the longitudinal direction of the supportive spring base or of the mattress arranged thereon. By contrast, the spring slats 10 run transversely with respect to the longitudinal struts 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com