Inline skate with a braking system

a braking system and roller blade technology, applied in the field of roller blades, can solve the problems of difficult cleaning of trace of stain, short distance, uneven etc., and achieve the effect of improving control and braking effect, improving the appearance of roller blades, and preventing trace of stain from leaving on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

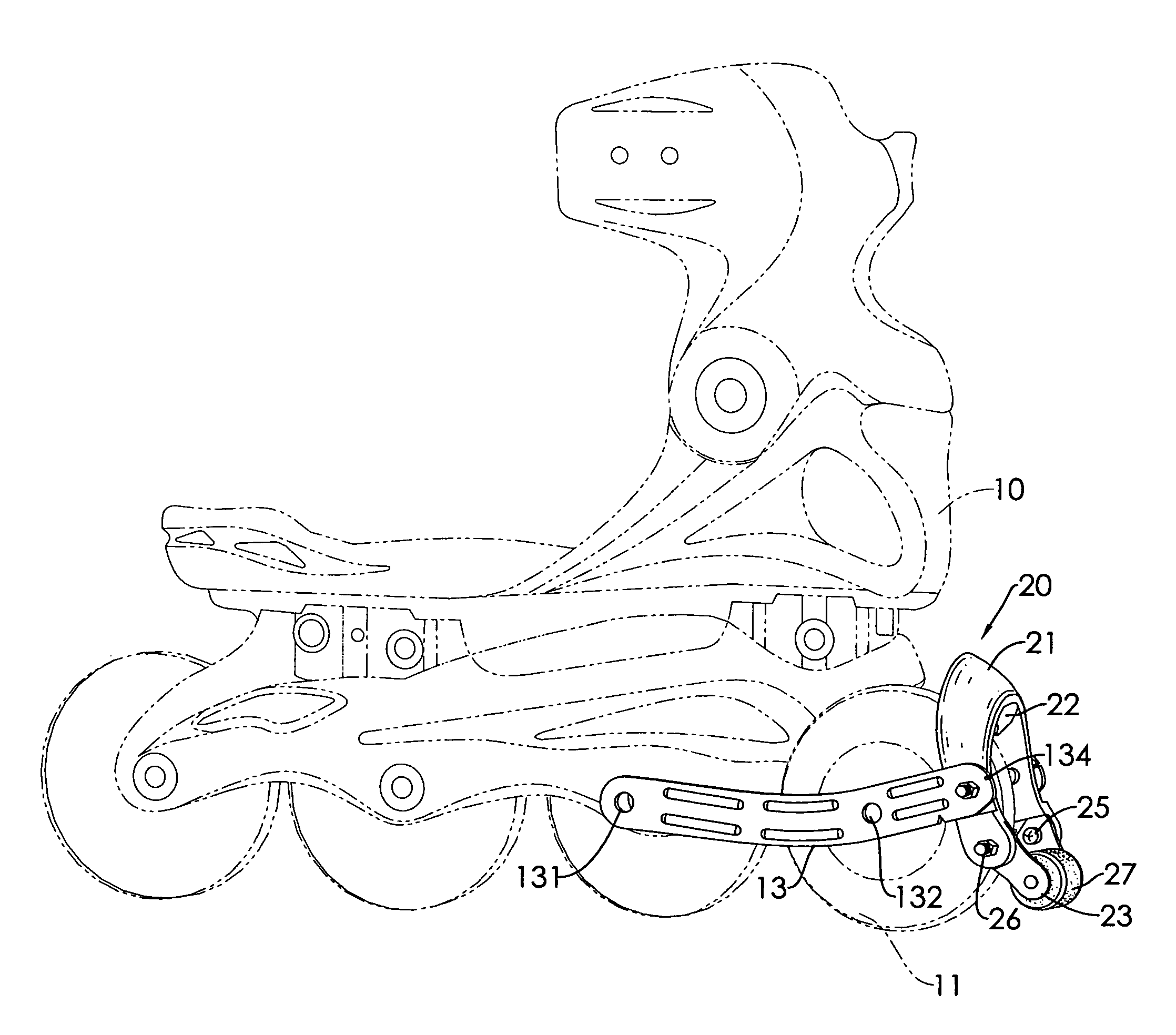

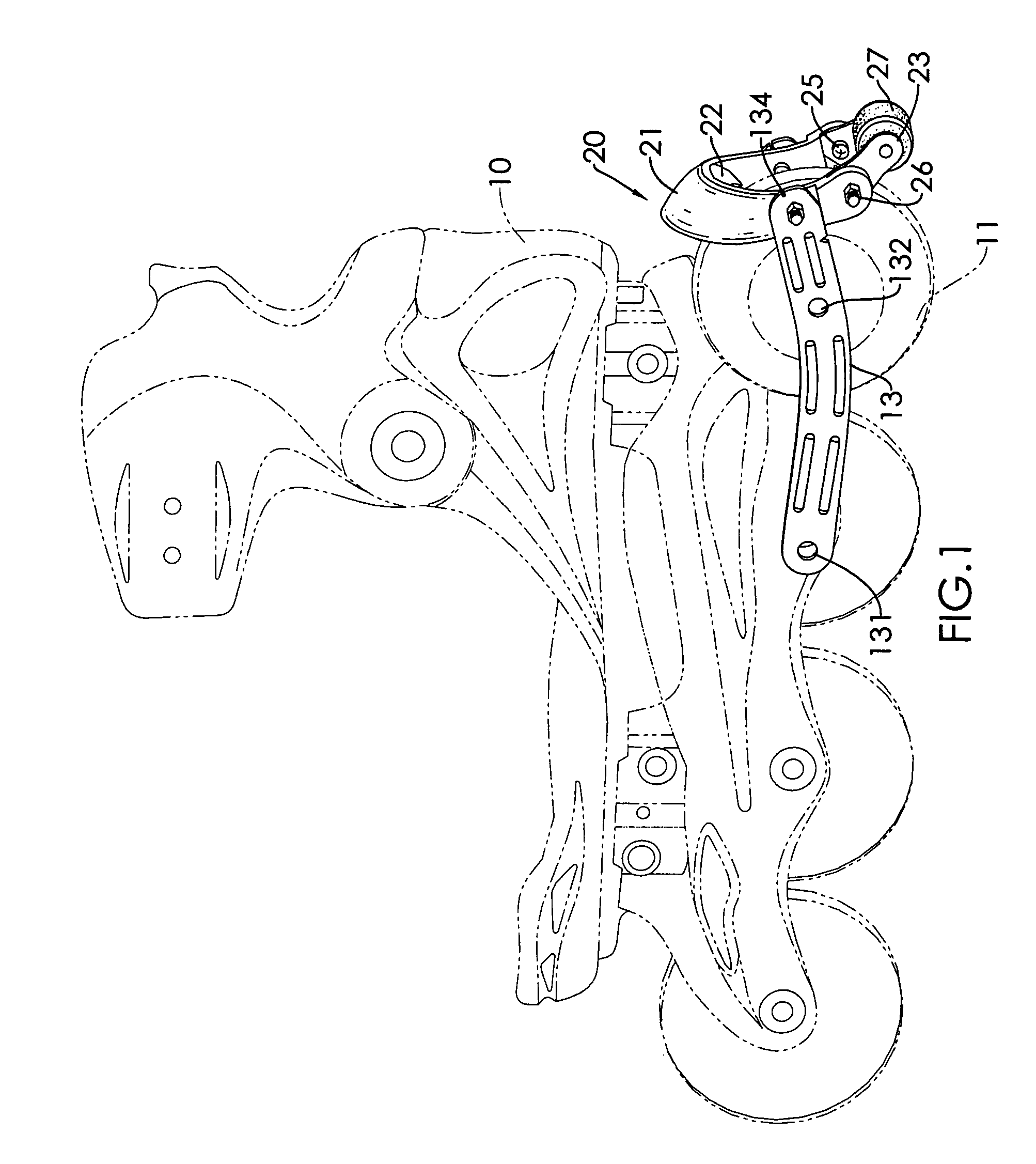

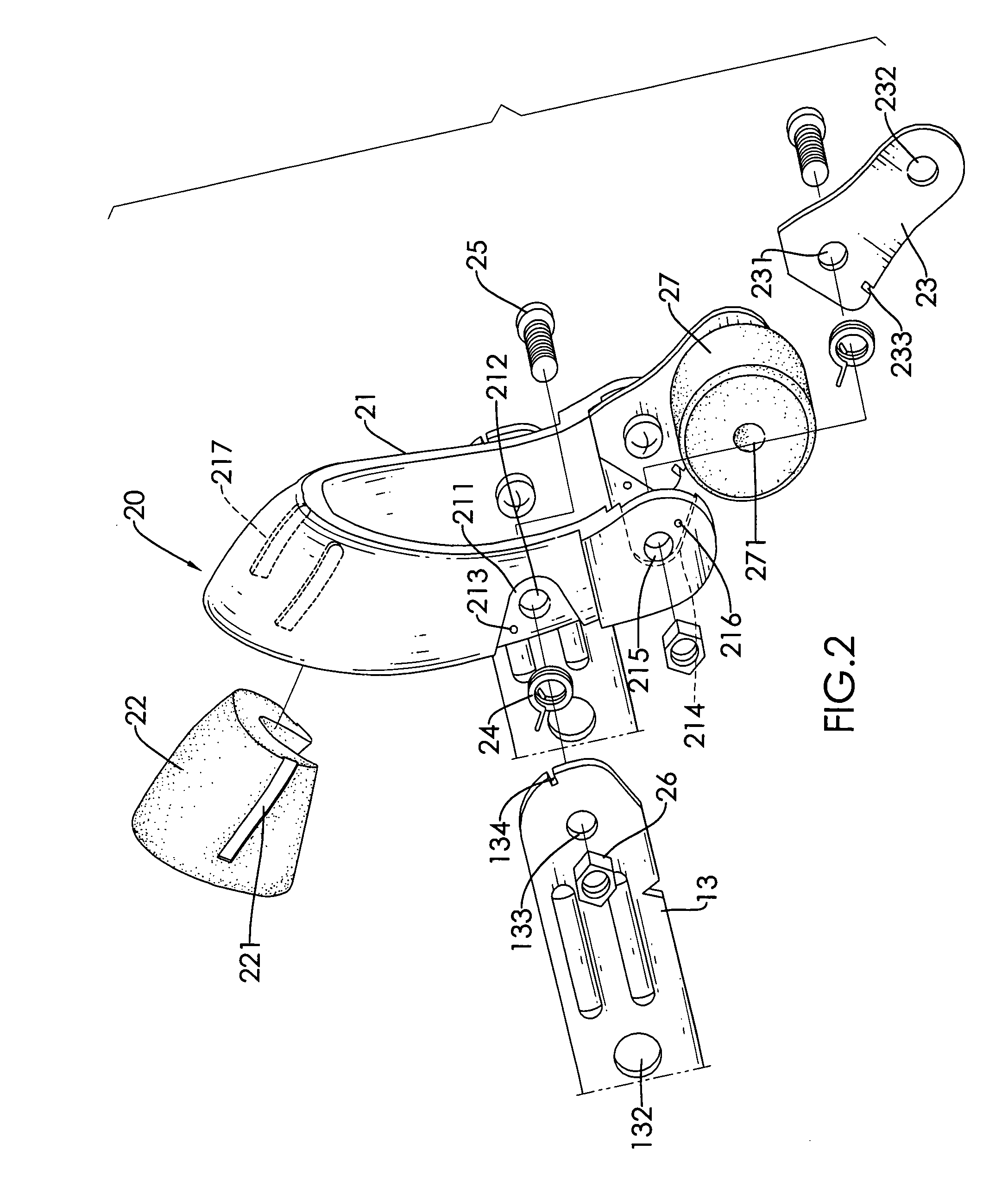

[0022]With further reference to FIGS. 1, 2, 6 and 7, a roller blade with a braking system in accordance with the present invention comprises a boot (10), two frames (13) and a braking assembly (20, 30, 40).

[0023]The boot (10) has a front end, a bottom, a rear end and multiple rollers (11). The rollers (11) are rotatably mounted on the bottom of the boot (11) from the front end to the rear end of the boot (10). Each roller (11) has two sides and a center.

[0024]The frames (13) are respectively mounted on two sides of the rollers (11) of the boot (10) and each frame (13), are separate to each other and each have a front end, a center, a rear end, a front hole (131), a center hole (132), a rear hole (133) and a rear cutout (134). The front hole (131) is formed through the front end of the frame (13). A bolt extends through the front hole (131) of the frame (13) and is screwed into the center of the roller (11) that corresponds to the front end of the frame (13). The center hole (132) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com