Golf club head and method for making it

a golf club and head technology, applied in the field of golf club head, can solve the problems of decreasing the versatility of the golf club head, and achieve the effects of increasing the travel distance of the golf ball, reducing the difficulty of adjusting the changeable zone, and increasing the hitting for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

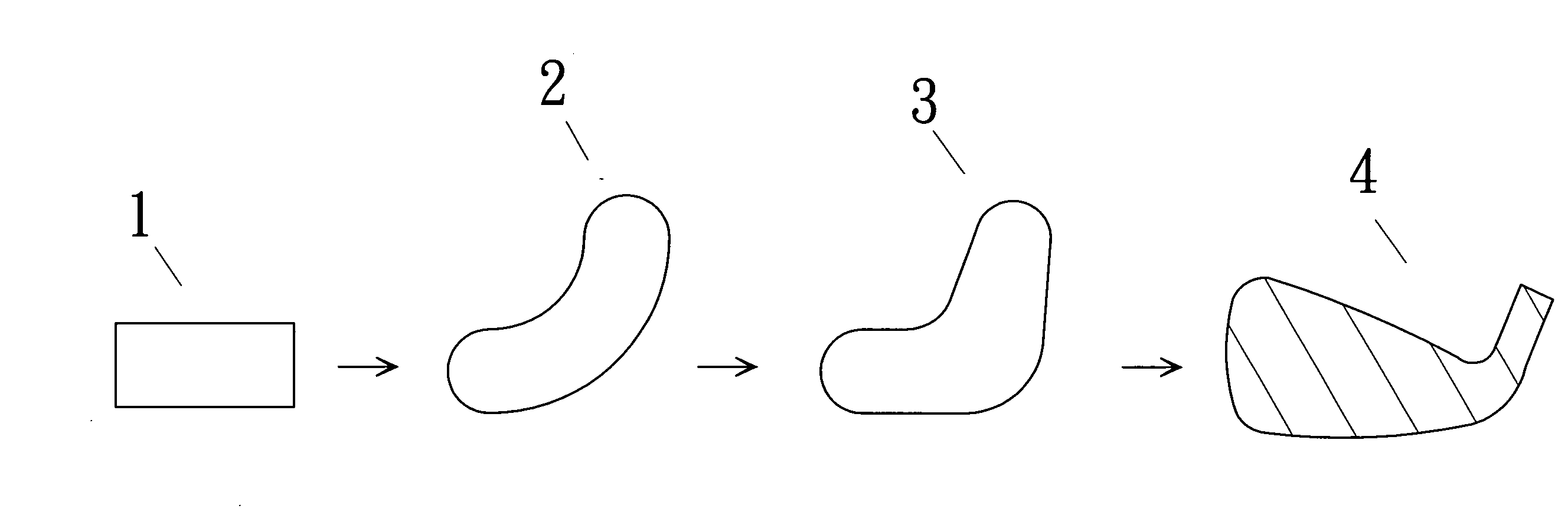

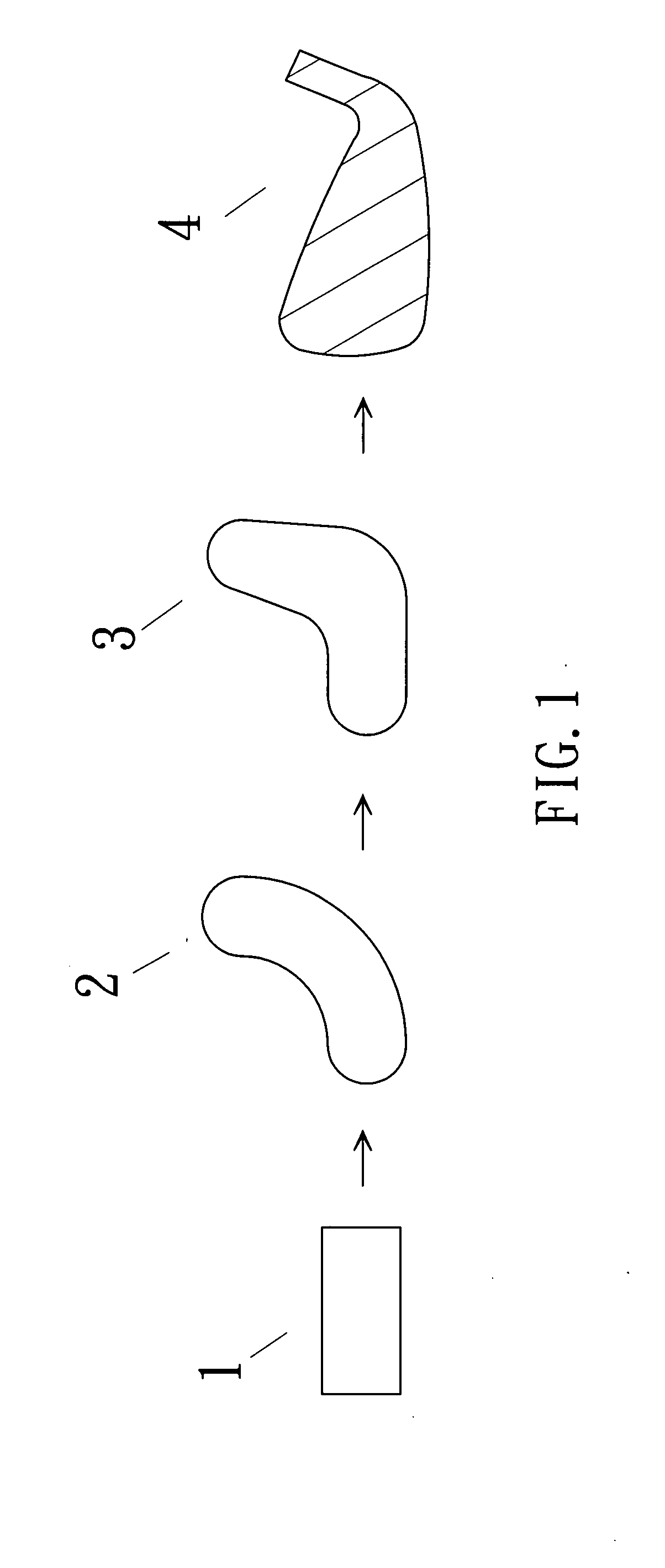

[0017]Referring to the drawings and initially to FIG. 1, a method for making a golf club head in accordance with the preferred embodiment of the present invention comprises a first step of providing a circular bar 1, a second step of working the circular bar 1 by a bending and stamping process to form a first blank 2, a third step of working the first blank 2 by a rough forging and stamping process by two to three times to form a second blank 3, a fourth step of working the second blank 3 by a finish forging and stamping process by one to two times to form a third blank 4, and a fifth step of working the third blank 4 by a lapping and coloring process to form a product of a golf club head.

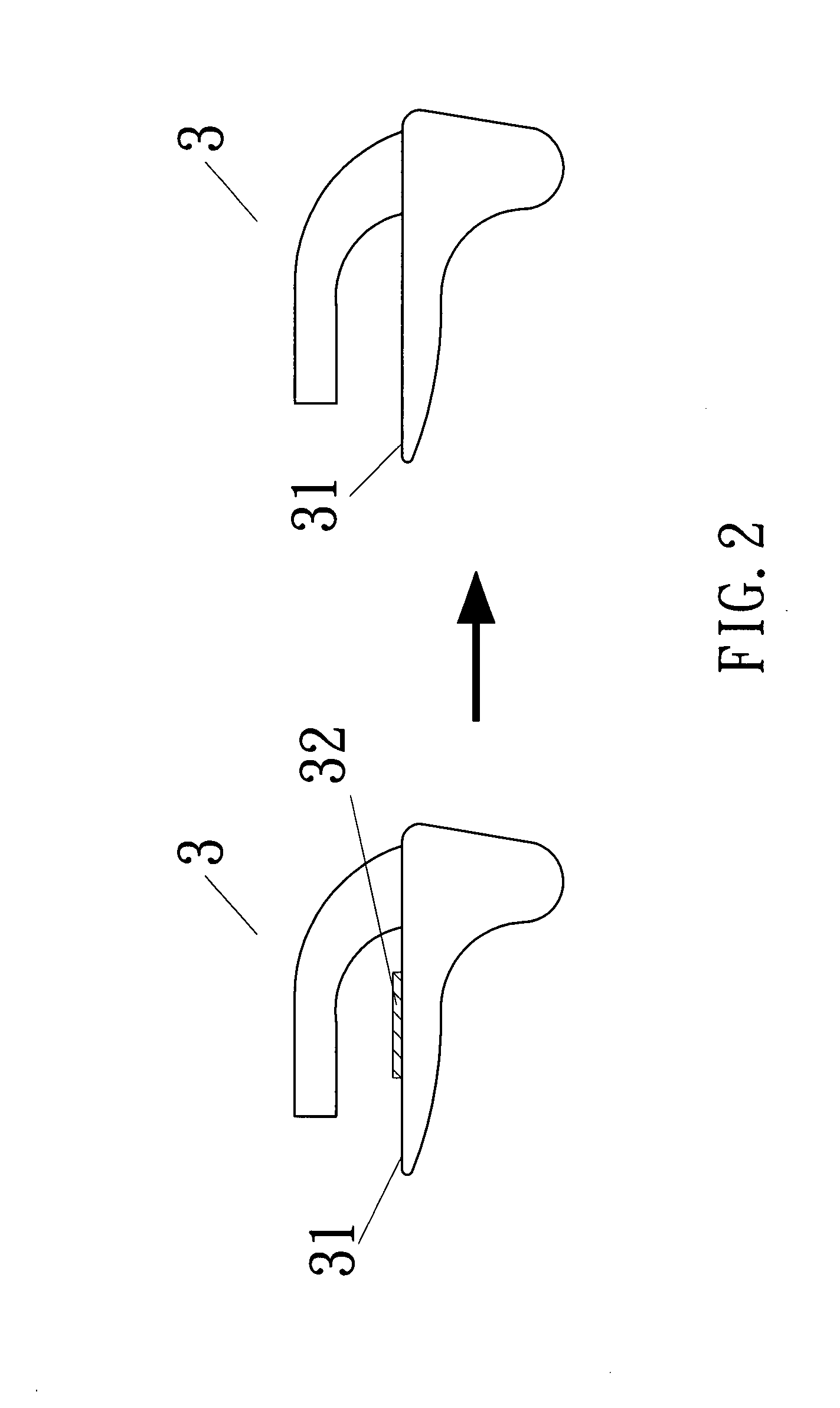

[0018]Referring to FIGS. 2 and 3, the second blank 3 has a hitting face 31 provided with a changeable zone 32 which is encompassed by and located at a middle position of the hitting face 31. In the preferred embodiment of the present invention, the changeable zone 32 is a protruding portion protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com