Metal cutting band saw with suspended saw frame

a technology of metal cutting band saw and saw frame, which is applied in the direction of metal sawing device, sawing device, metal sawing apparatus, etc., can solve the problem of compact material flow direction in the new arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

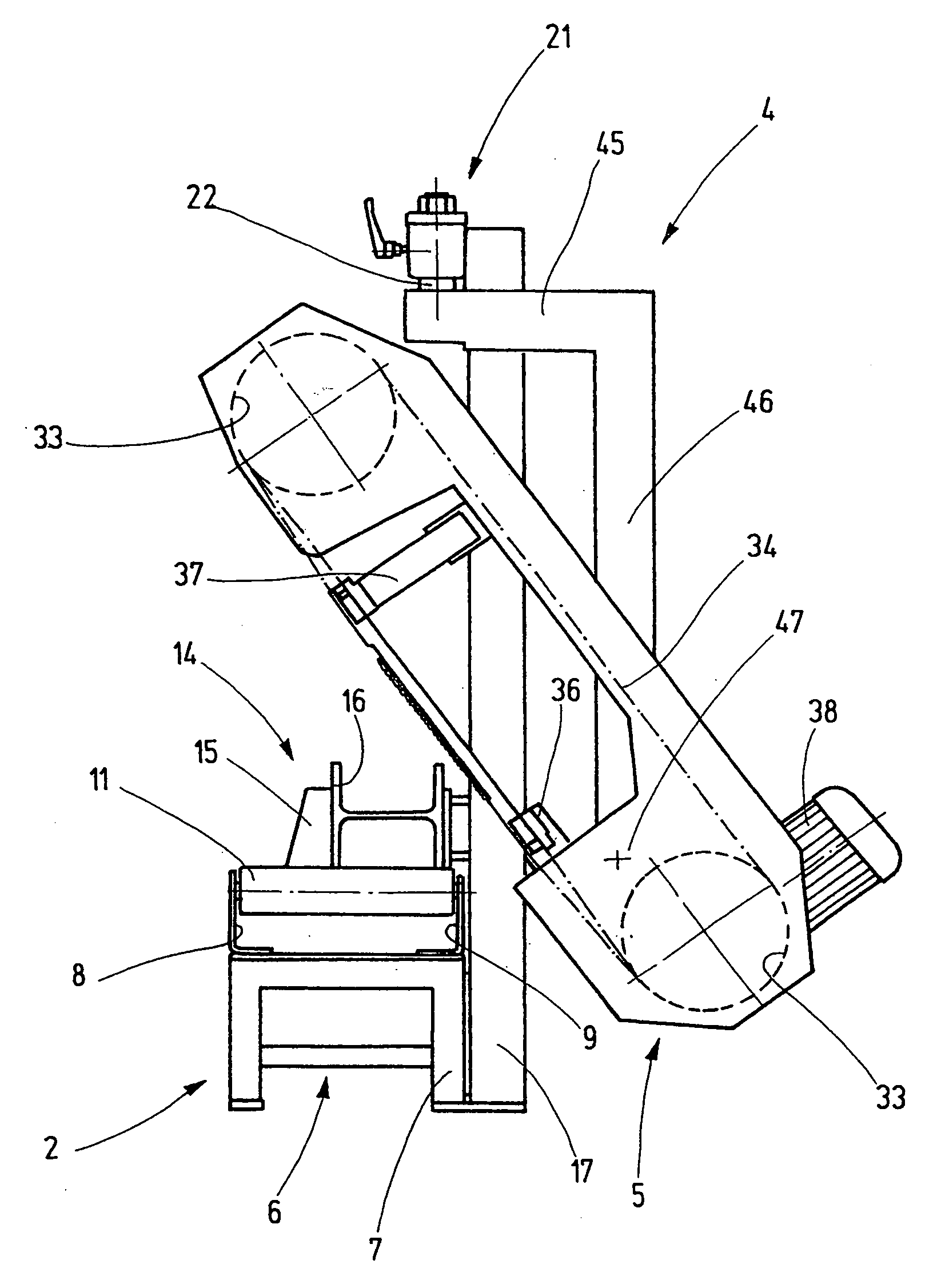

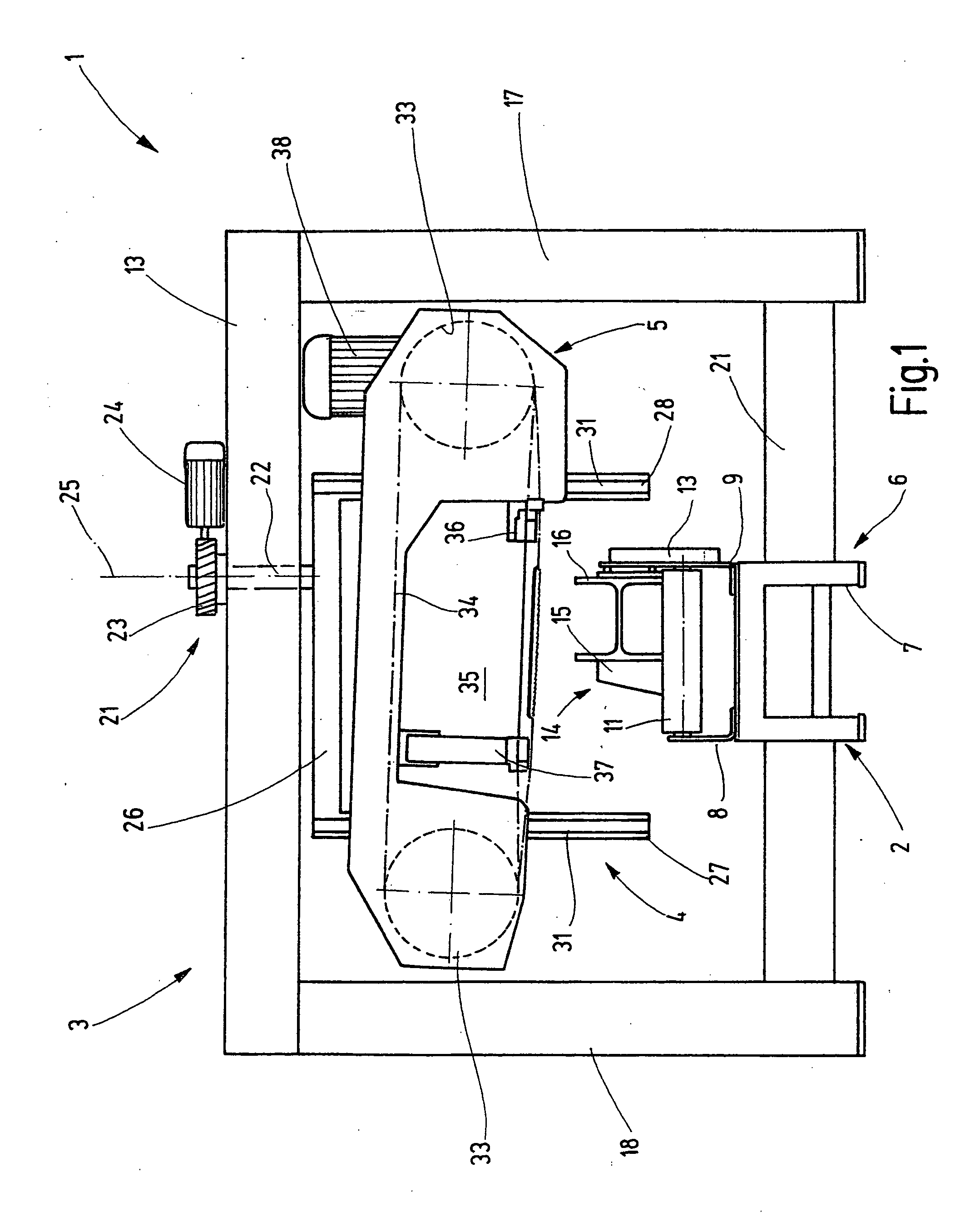

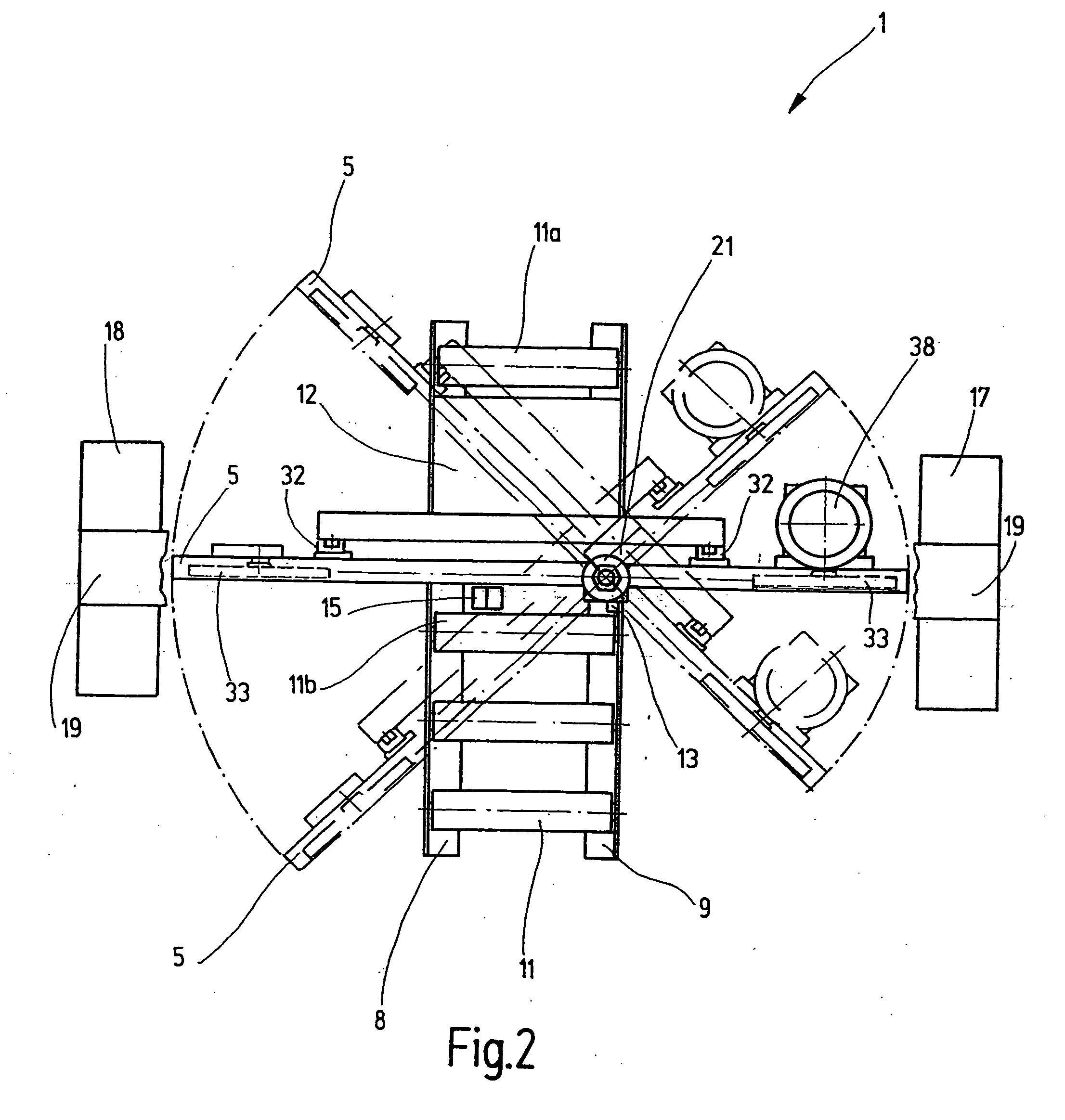

[0024]FIGS. 1 and 2 show a metal cutting band saw 1 according to the invention. The metal cutting band saw 1 has a machine frame 2, with a gantry shaped main carrier 3 that is mounted on the floor foundation spanning the machine frame. An intermediate carrier 4 that serves to hold a saw frame 5 is pivotally supported on the main carrier 3.

[0025]The machine frame 2 consists of a lower frame 6 with legs 7. Two angled profile rails 8 and 9 that extend continuously in the longitudinal direction are mounted on the upper side of the frame 6. Several rollers 11 that serve as a workpiece support are arranged axially parallel and adjacent to one another between the angled profile rails 8 and 9. The rollers 11 can rotate freely and their upper sides are tangent to an imaginary common plane. Between the rollers 11a and 11b, a plate like support table 12 lies on the lower frame 7 between the profile rails 8 and 9. In its initial state, the support table 12 has a flat, smooth surface that lies a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| miter angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com