Heat Insulating Container

a technology of insulating containers and heat, which is applied in the direction of domestic cooling devices, lighting and heating devices, transportation and packaging, etc., can solve the problems of not producing satisfactory strength in the radial direction, and achieve excellent advantages, reduce the number of steps and materials, and heat shrinkability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0034]Now, the description will be made for the present invention with reference to the attached drawings.

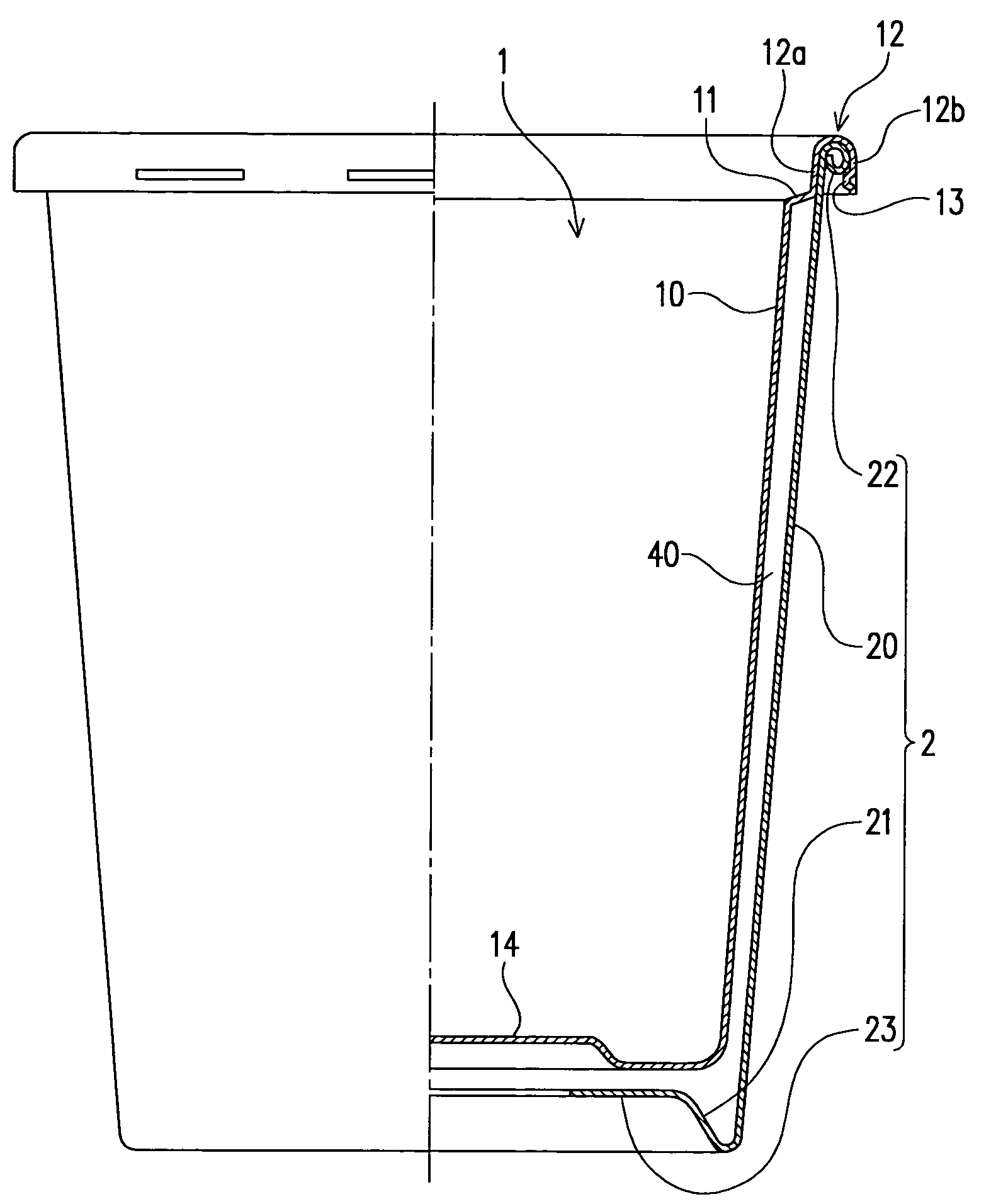

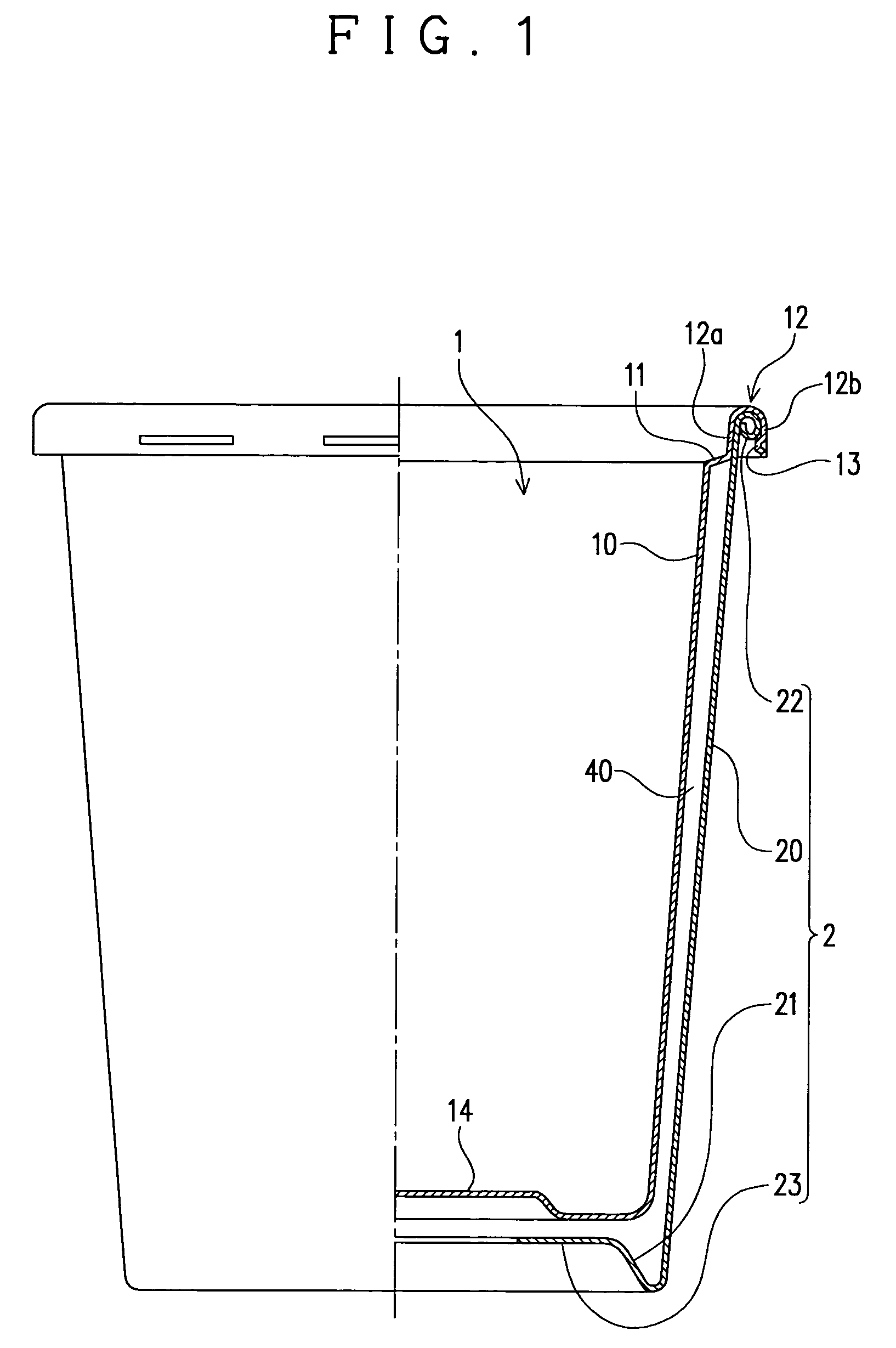

[0035]A heat insulating container of this embodiment is made up of a container body 1 having a bottomed tubular shape, and an outer shell 2 that covers a peripheral wall 10 of the container body 1, as illustrated in FIG. 1.

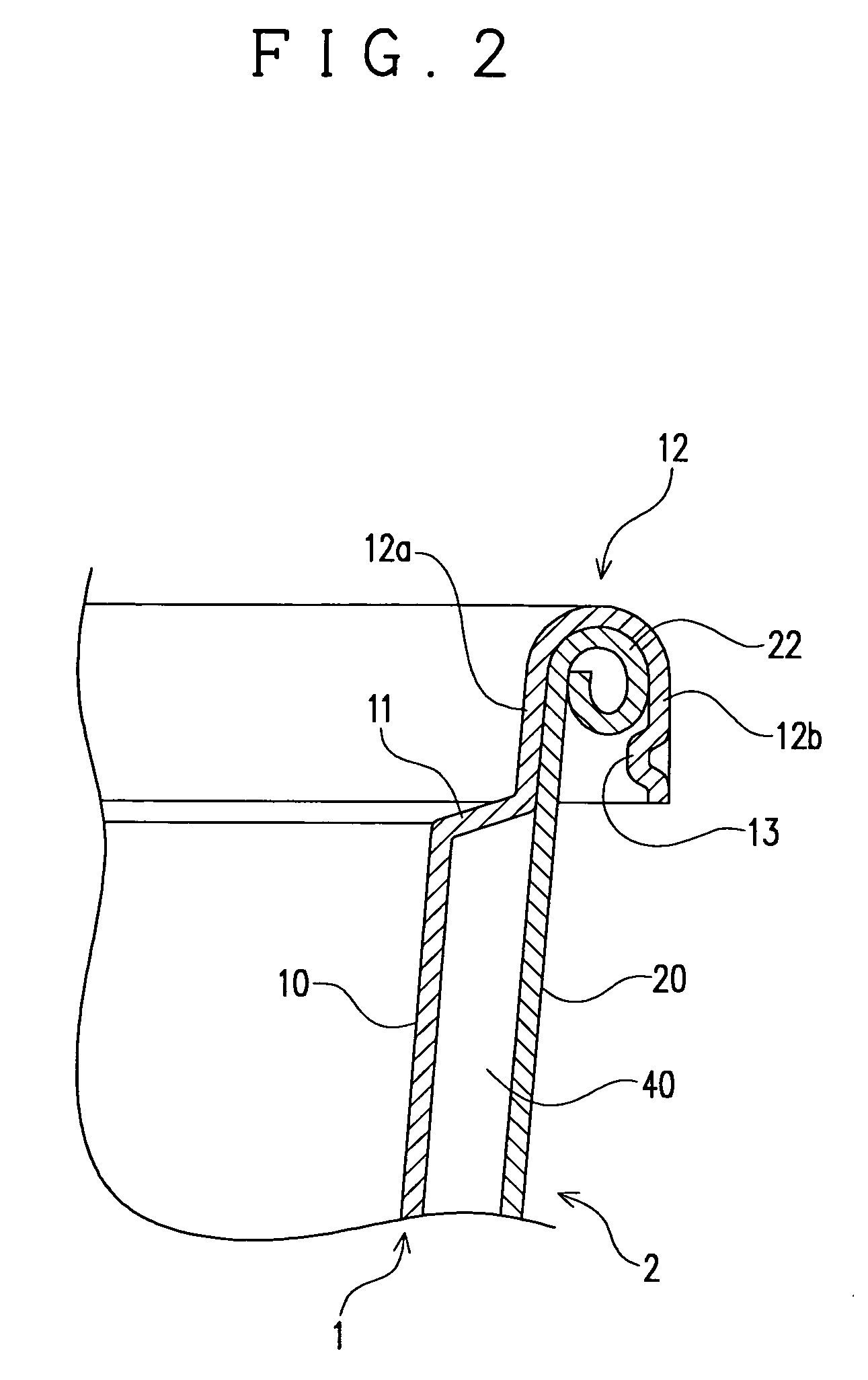

[0036]The container body 1 is a resin molded product molded by a molding technique such as injection molding, blow molding, vacuum molding or pressure molding. The container body 1 is formed into a tubular shape with the peripheral wall 10 being decreased in diameter towards the lower end. An upper end of the peripheral wall 10 of the container body 1 is provided with an annular connection portion 11 that extends outward and has an outer peripheral edge connected with a lower end of an inner peripheral piece 12a of an annular flange portion 12 having a downwardly opening U-shaped cross section.

[0037]An outer peripheral piece 12b of the flange portion 12 has pl...

second embodiment

[0103]The lower peripheral wall portion 10b has an opening edge of the upper end connected to the upper peripheral wall portion 10a via the connection portion 5, and a lower end opening closed by the bottom portion 14. The lower peripheral wall portion 10b is formed into a tubular, inverted conical shape (tubular body having an inverted truncated conical shape) with an outer diameter and an inner diameter decreasing towards the lower end. Likewise the lower tubular part 114 of the second embodiment, the lower peripheral wall portion 10b of this embodiment is made up of a thick tubular section 114a close to an upper end opening connected to the connection portion 5, and a thin tubular section 114b connected to an opening edge of a lower end of the thick tubular section 114a with taking into account the flow of a resin during molding.

[0104]Since the lower peripheral wall portion 10b is, as described above, connected to the upper peripheral wall portion 10a via the connection portion 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com