Non-Rotating Coupling Device

a coupling device and non-rotating technology, applied in the direction of couplings, mechanical equipment, spray nozzles, etc., can solve the problems of not providing the resistance necessary to adjust the accessories, the coupler does not allow the user to orient the connector, and the coupler does not allow the user to use them. to achieve the effect of backward compatibility and improved design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]It is to be understood by one of ordinary skill in the art that the present discussion is a description of exemplary embodiments only, and is not intended as limiting the broader aspects of the present invention. The following exemplary embodiment is provided to further illustrate the invention and is not to be construed to unduly limit the scope of the invention.

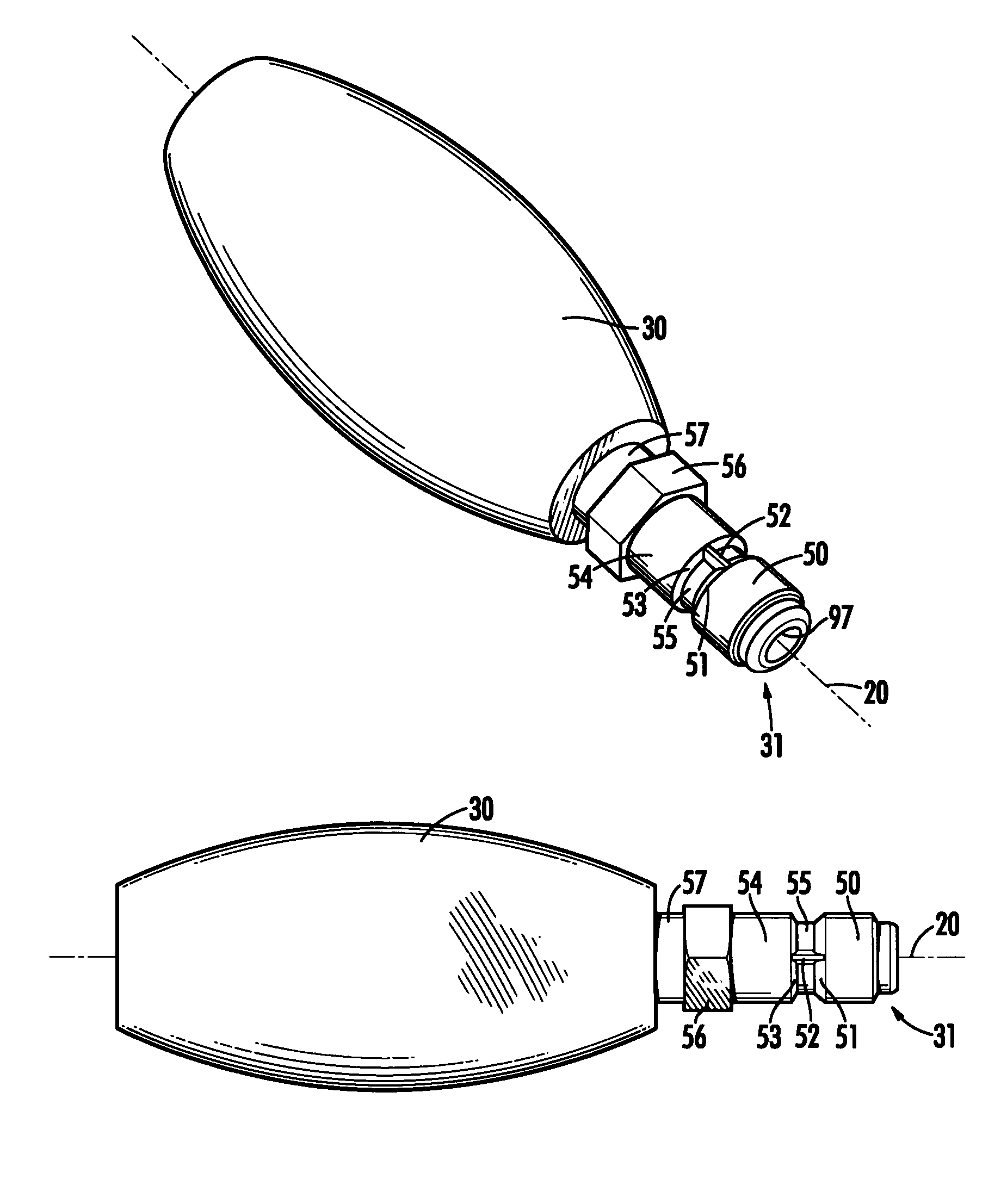

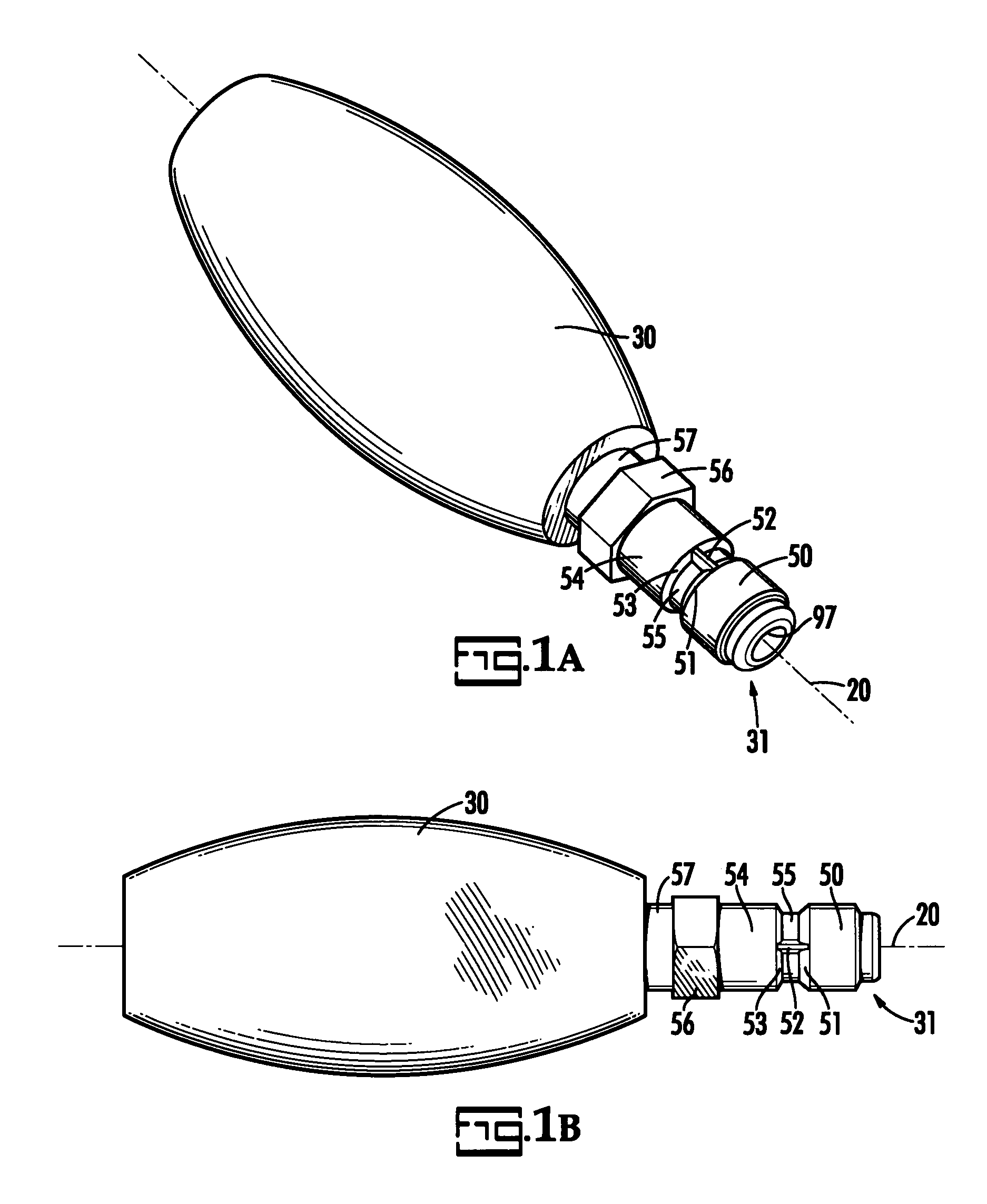

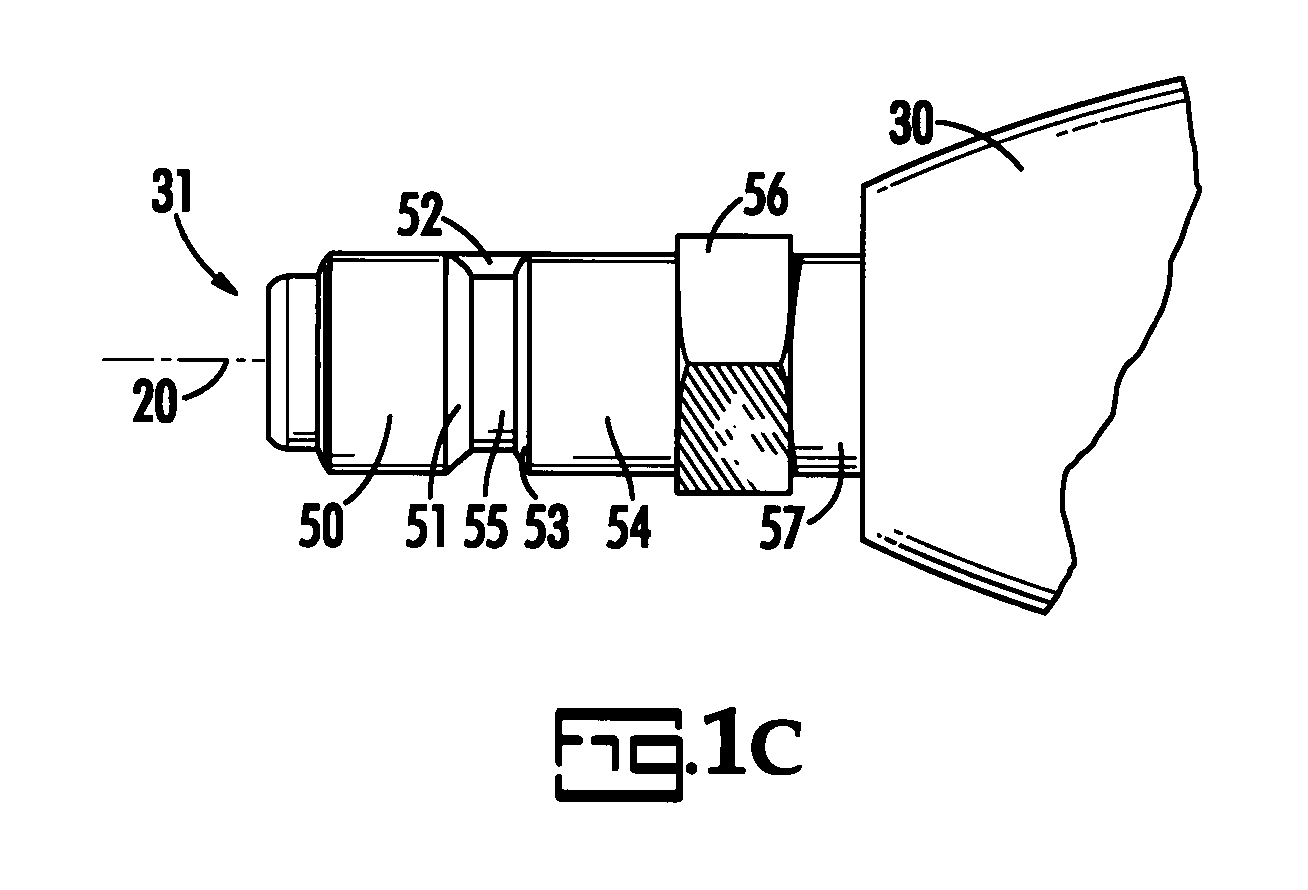

[0022]Referring to FIGS. 2, 3A and 3B, the non-rotating quick connector 10 comprises a male connector 31, a female connector 67, a tubular sleeve 62, a compression spring 63, a lock ring 60, O-rings 61 and one or more locking balls or pins 64.

[0023]Male connector 31 includes an internally or externally threaded portion 57 forming an attachment end integrally connected to a male plug or coupling portion or end 50 by means of a shoulder portion 54 intermediate the length of the plug 31. Male plug 31 further includes a fluid or air channel 97 which extends either partially or completely through the male connector 31, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com