Cut, abrasion and/or puncture resistant knitted gloves

a technology of abrasion and/or puncture resistance and knitted gloves, which is applied in the field of knitted gloves, can solve the problems of brittle high-strength fibers, easy abrasion of conventional fabrics, and loss of mass, so as to improve the overall abrasion resistance of the glove assembly, and improve the protective knitted glove assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

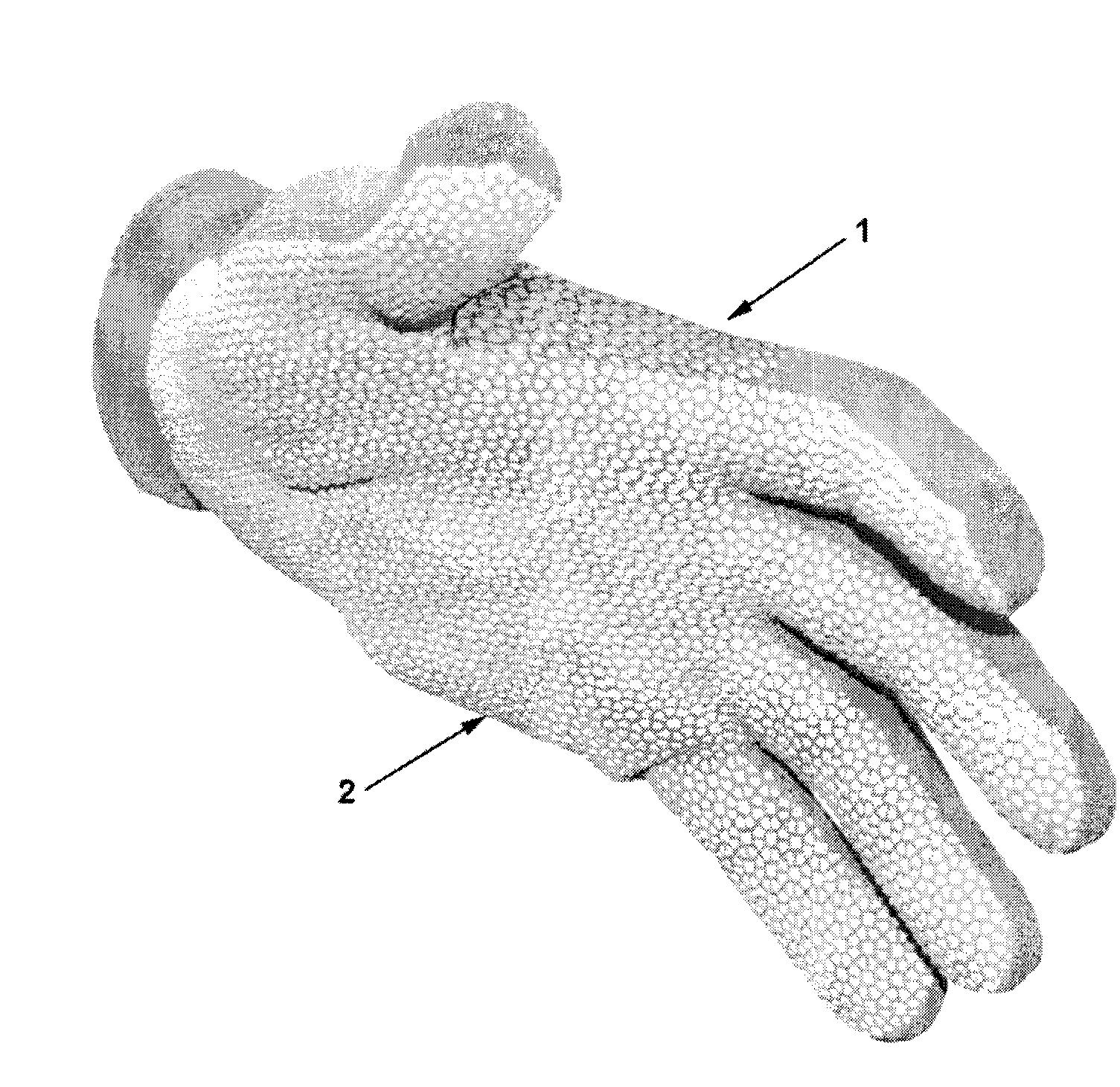

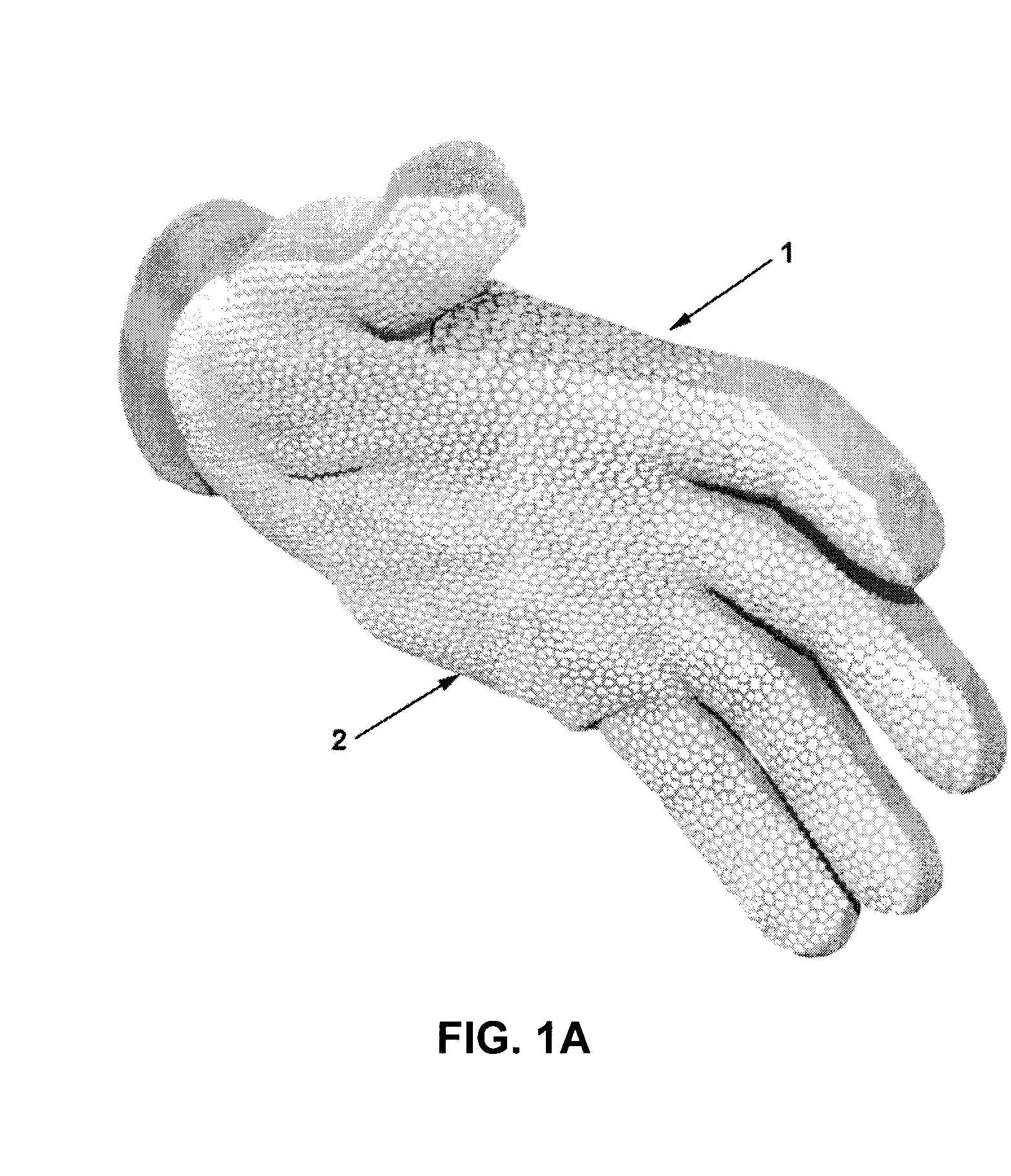

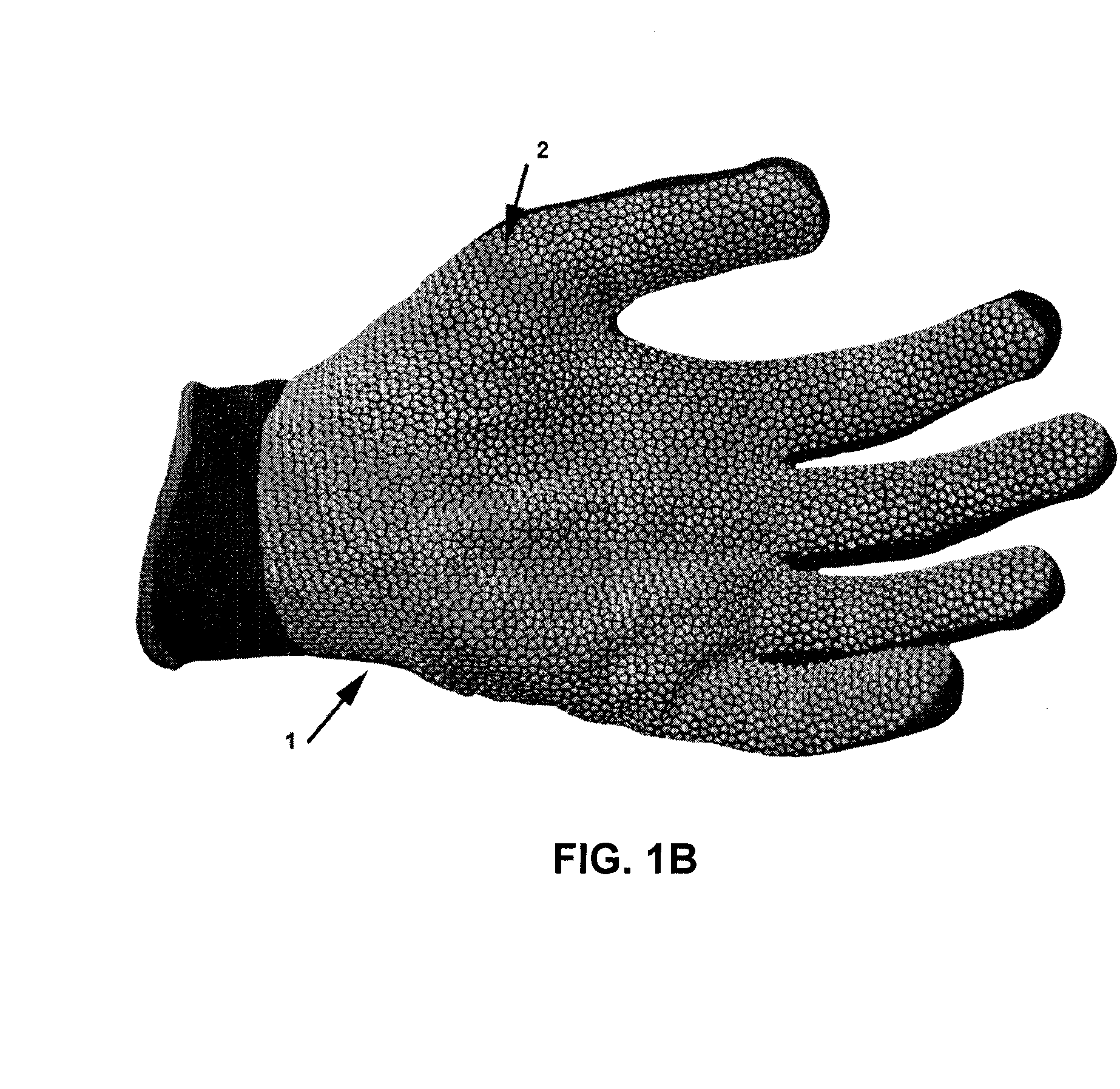

[0024]FIG. 1A shows a front view of one embodiment of the glove assembly of the present invention where guard plates 2 between the thumb and forefinger region are visible. As shown in FIG. 1A, guard plates 2 cover the generally planar palm side of the glove assembly 1, including the palm side of the fingers. The portion of the glove assembly 1 with guard plates 2 between the thumb and forefinger is effectively on the side of the forefinger and in the crotch between the forefinger and thumb, surfaces that are effectively non-coplanar and non-parallel with the guard plates on the palm of the glove assembly. The edges of the guard plates 2 on the side of the forefinger and in the thumb crotch are positioned adjacent to the edges of the guard plates on the palm. FIG. 1B shows the palm side of glove assembly 1. FIG. 1C shows glove assembly 1 from the side of the back of the hand. An array of guard plates 2 is shown on the sides of the thumb and forefinger and in the crotch of the forefin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com