Tracked vehicle road wheel puller

a technology for pulling wheels and vehicles, applied in vehicle components, metal-working hand tools, metal-working apparatus, etc., can solve the problems of wheel being forcibly disjoined from its associated hub, wheel being removed by force, wheel rust or other chemical erosion, etc., to achieve the effect of quick and efficient removal of road wheels, without inflicting undue damage to wheels, hubs or tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

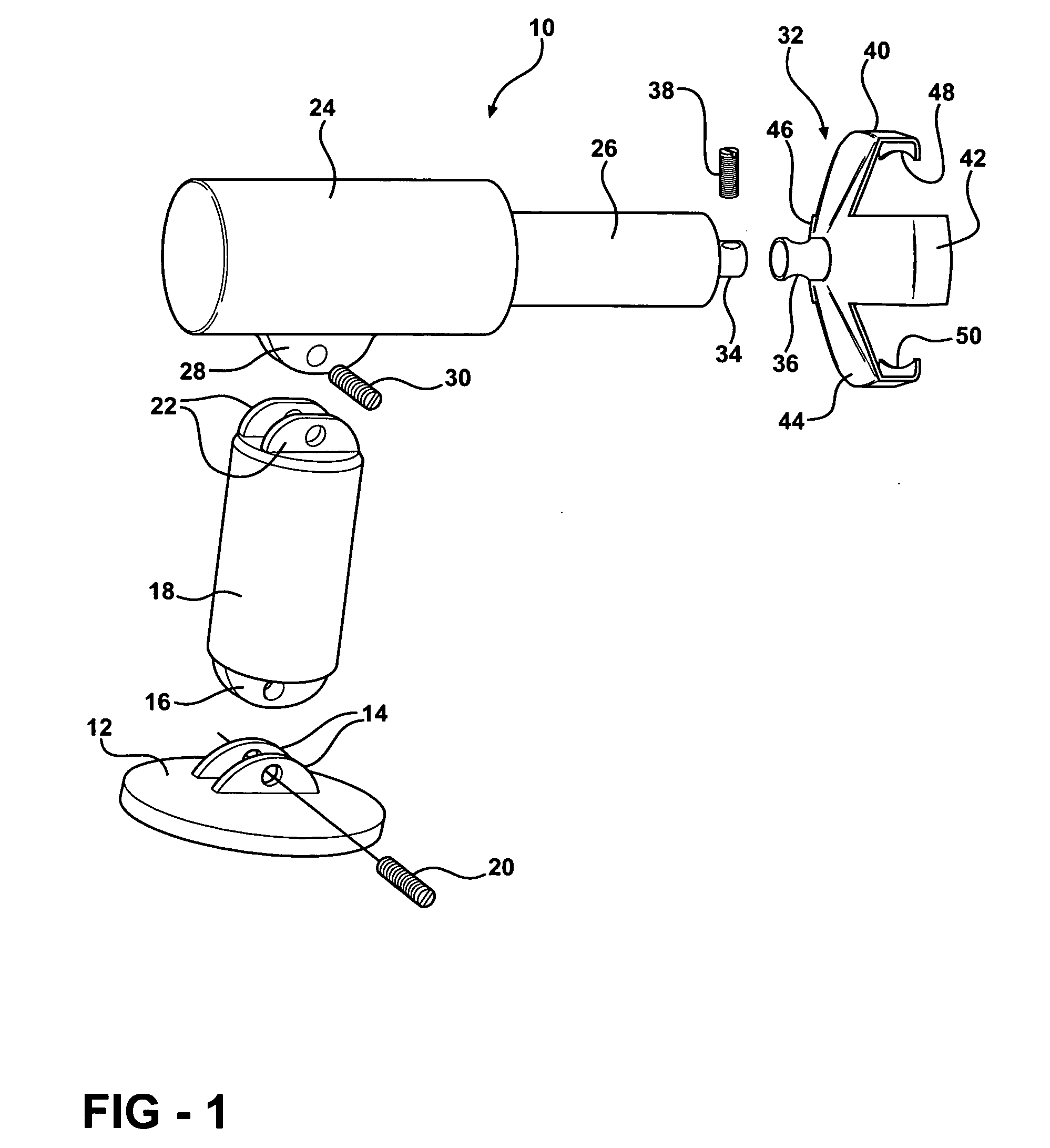

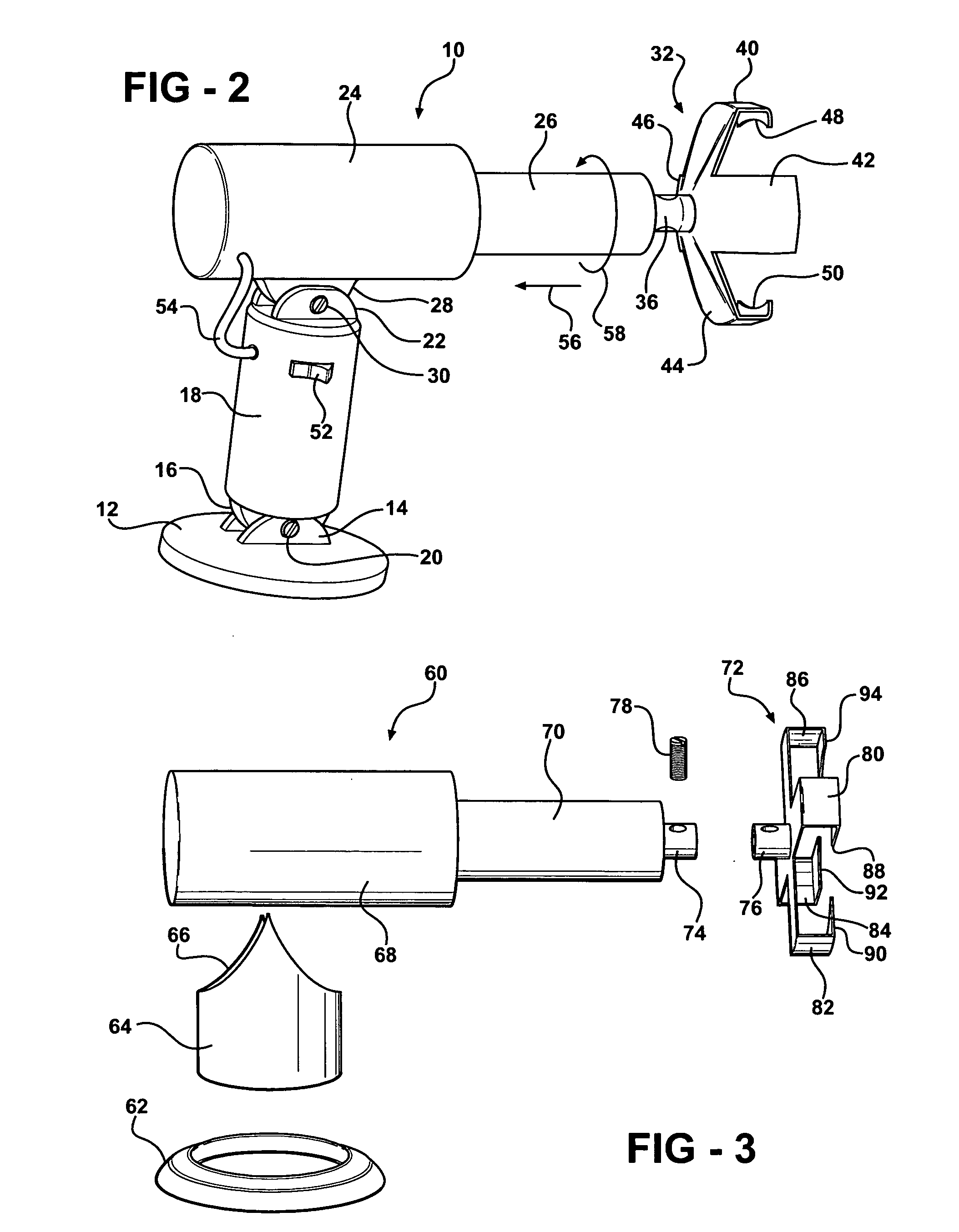

[0026]Referring now to FIG. 1, a powered road wheel puller device is illustrated at 10 according to a first preferred embodiment of the present invention. As previously described, the wheel puller device 10 teaches a ground supported, powered and articulated device exhibiting a clamp fixedly secured to a location of the road wheel and for forcibly removing the wheel from its axle by applying a combined pulling and twisting force.

[0027]As illustrated in FIGS. 1 and 2, the components of the wheel puller assembly 10 include the provision of a base plate 12, such having a substantially flattened and annular overall shape. A pair of spaced apart guide members 14 project from an upper surface of the base plate 12 and locate therebetween a downwardly projecting and seating member 16 associated with a cylinder leg 18. A pin, shown at 20 in FIGS. 1 and 2, seats through the aligning apertures established by the guide members 14 and sandwiched seating member 16.

[0028]A further pair of spaced a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twisting force | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com