System and method for vapor control in cryogenic freezers

a technology of cryogenic freezer and vapor control, which is applied in the field of cryogenic refrigeration and freezing systems, can solve the problems of increased costs of operating the cryogenic refrigeration system, inefficient cryogen usage, and water vapor deposition inside the freezer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]The following description sets forth the best mode presently contemplated for practicing the present cryogenic freezer system with vapor control. It is not to be taken in a limiting sense, but rather should be read in conjunction with the appended claims.

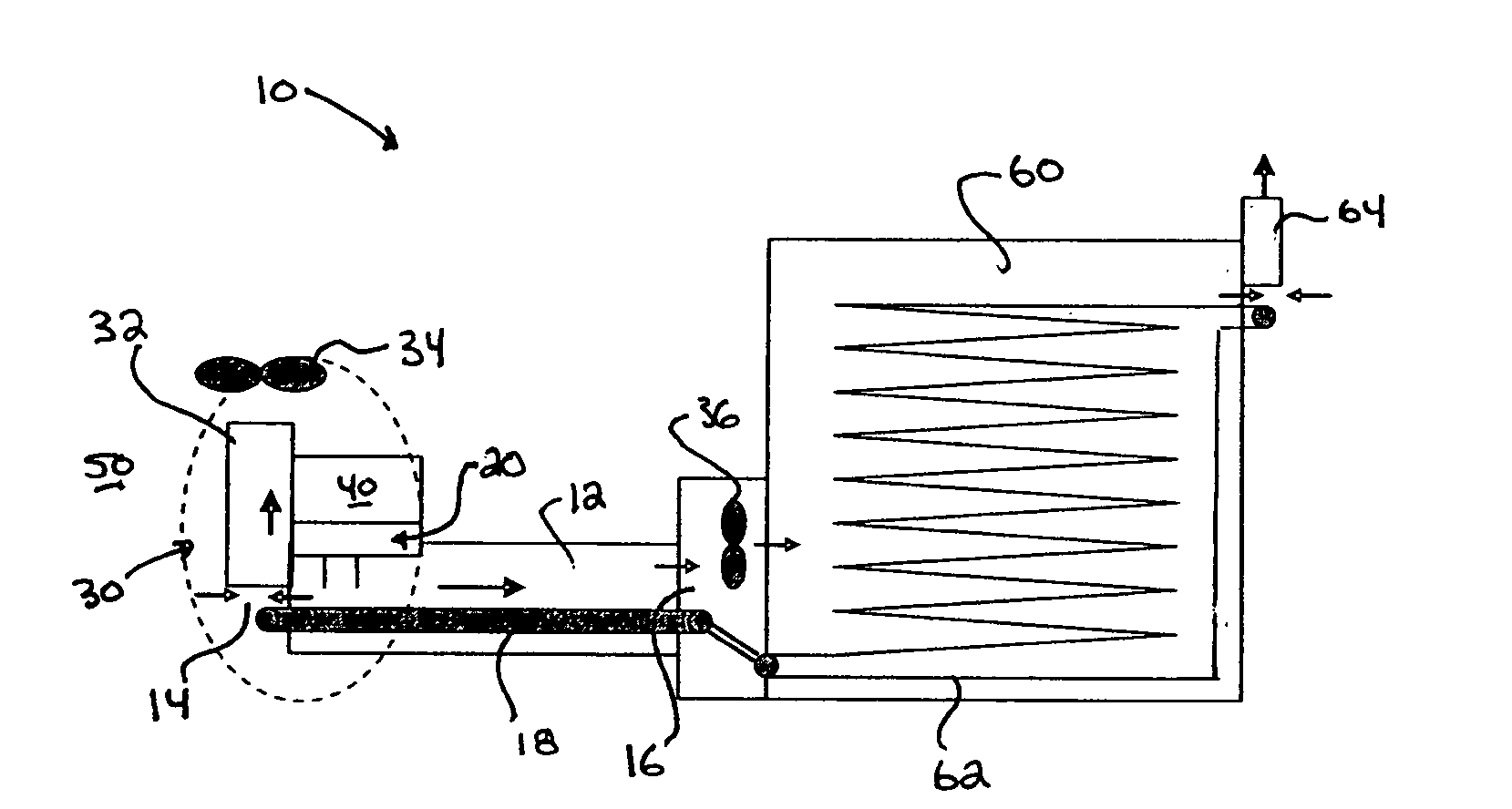

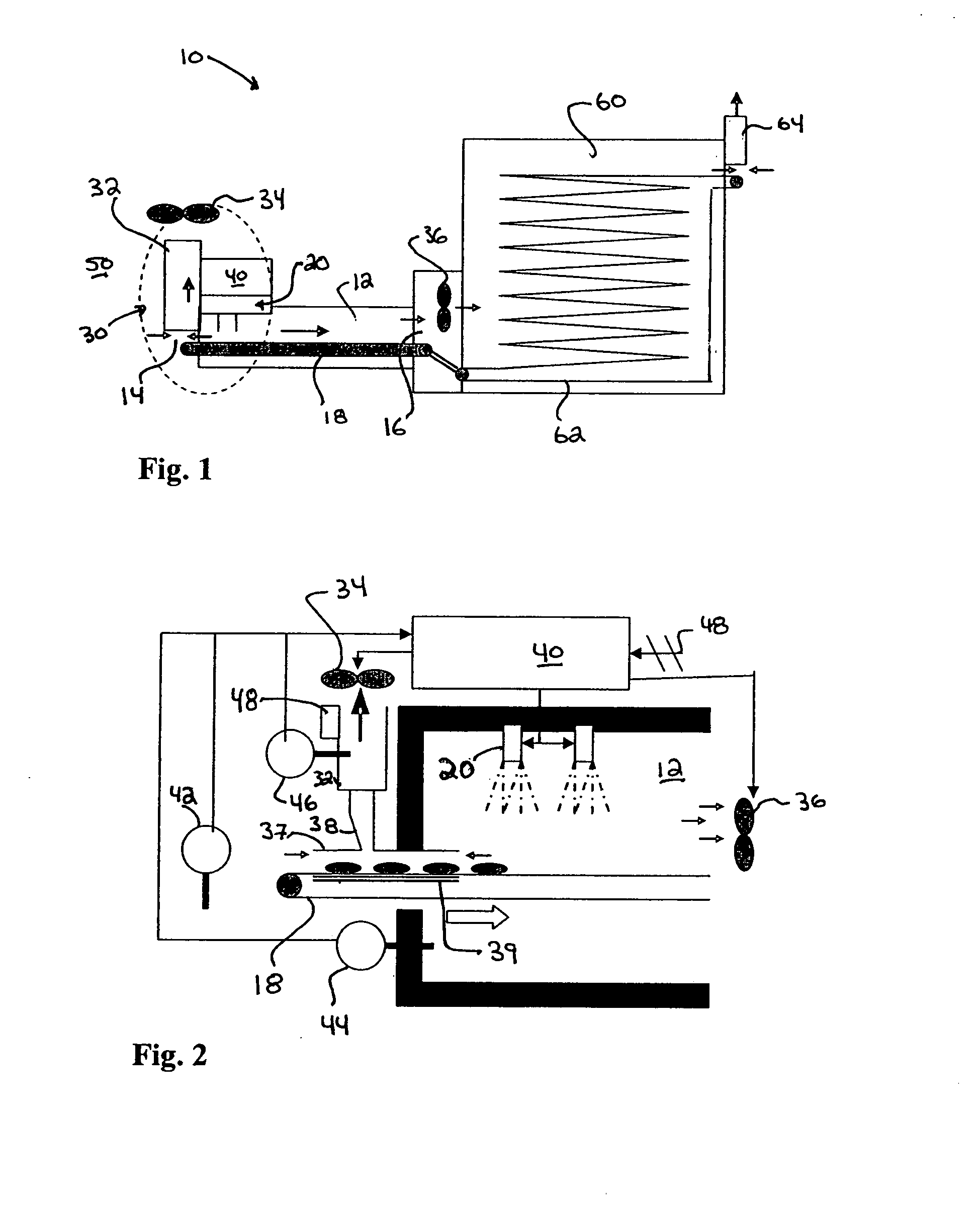

[0011]With reference to FIG. 1 and FIG. 2, there is shown an embodiment of the present cryogenic freezer system 10 with vapor control. As seen therein, the cryogenic freezer system 10 includes a first freezer compartment 12 having an entrance 14, an exit 16, and a conveyor 18 disposed therein for treating a food product. The freezer system 10 further includes a cryogen injection or supply subsystem 20 adapted to introduce a cryogen into the first freezer compartment 12 to treat the food product as well as an exhaust subsystem 30 and a vapor control subsystem 40. In the illustrated embodiment, the exhaust subsystem 30 preferably includes an exhaust duct 32 disposed proximate the entrance 14 of the first freezer compartment 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com