Folding construction platform

a construction platform and folding technology, applied in the field of construction platforms, can solve the problems of expensive transportation and storage of items, and achieve the effect of efficient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

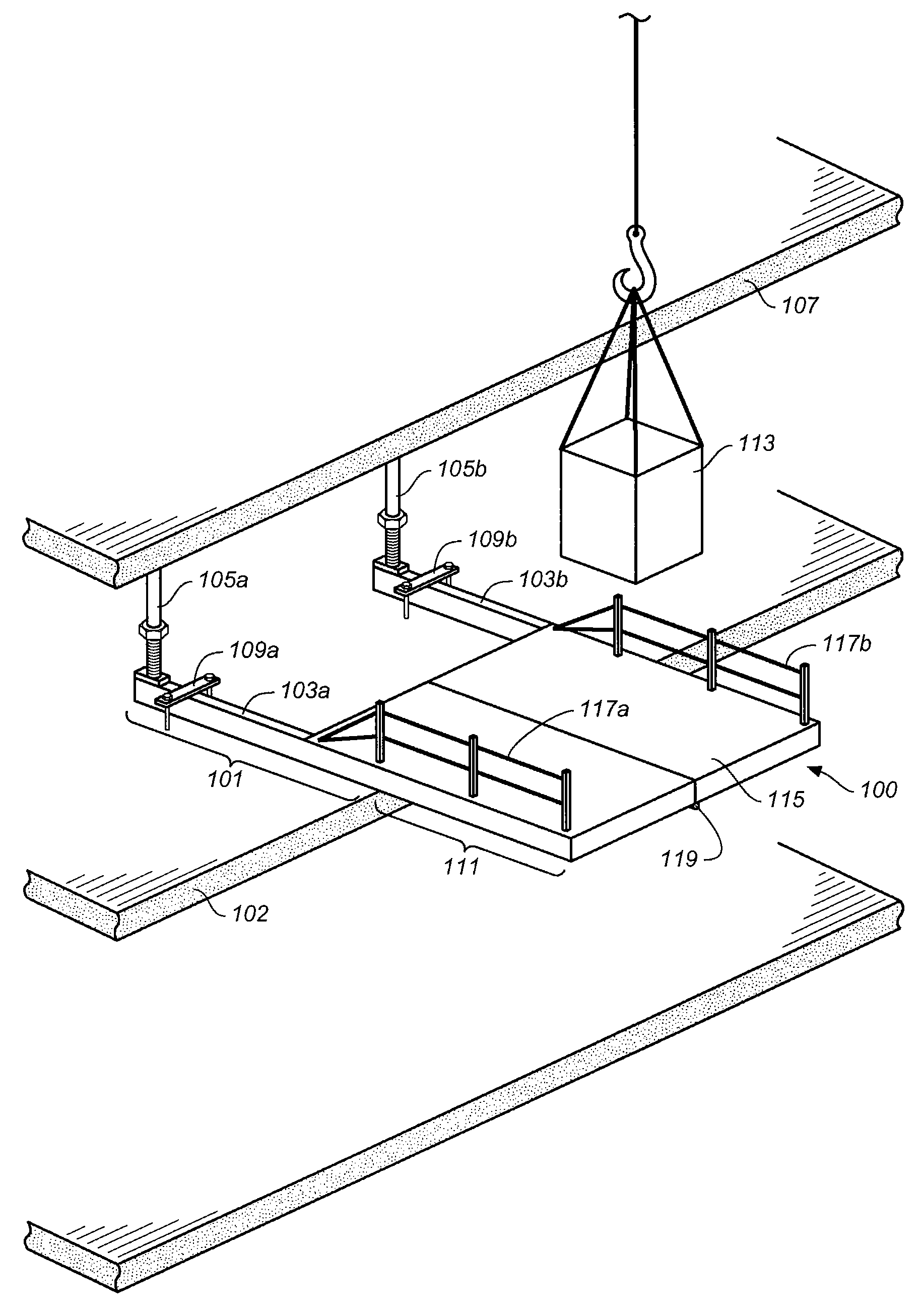

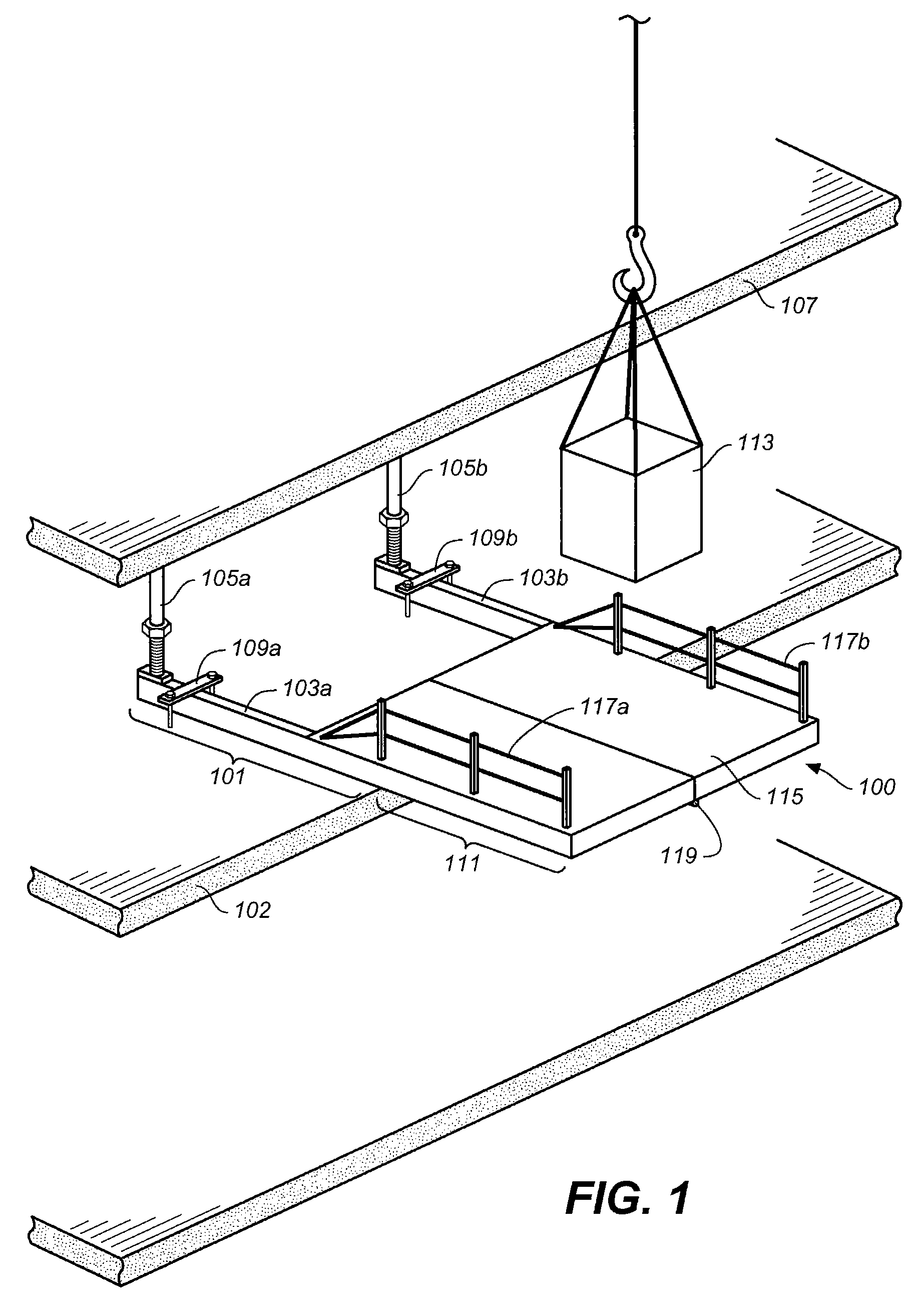

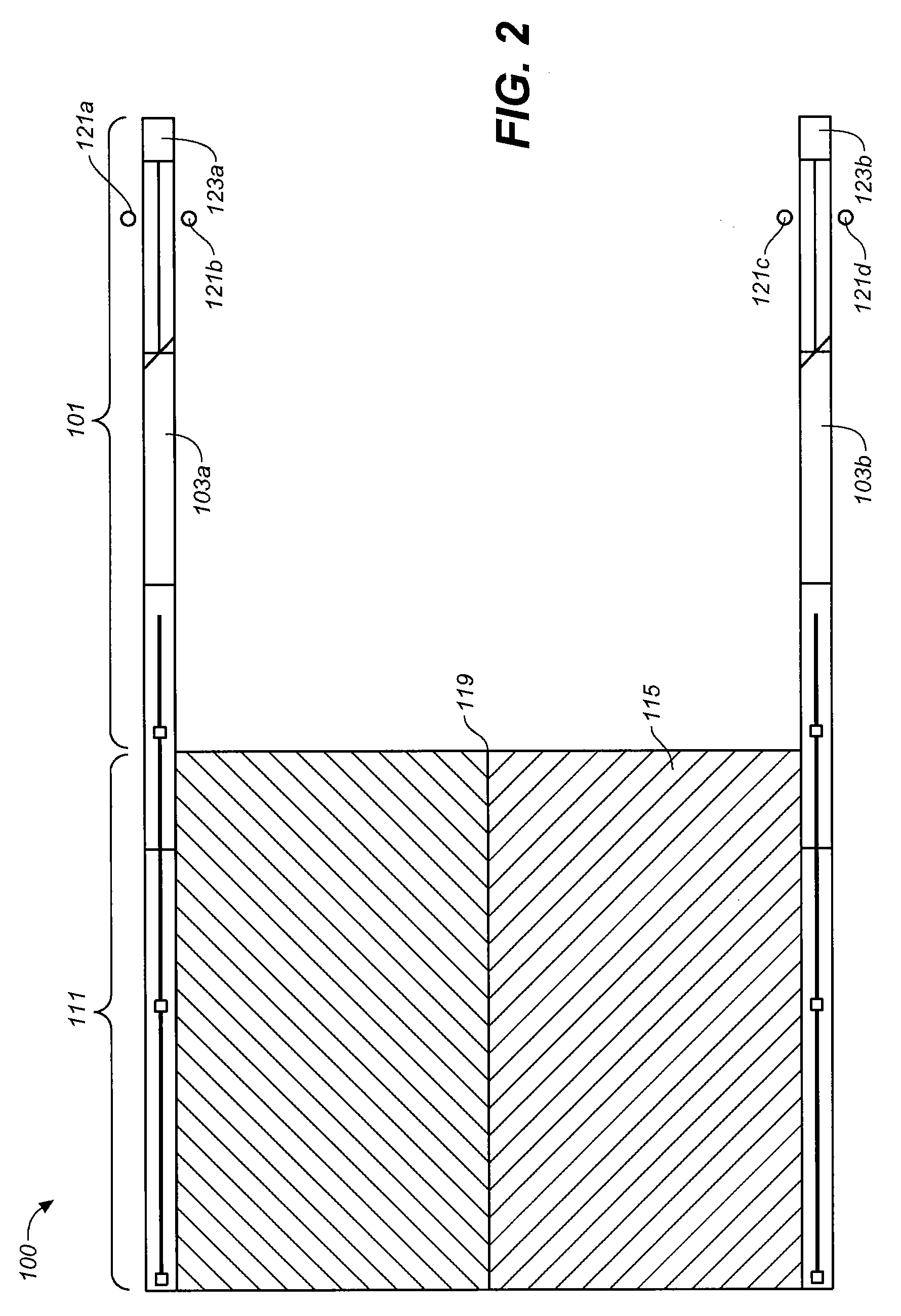

[0015]FIG. 1 shows a construction platform 100 according to an embodiment of the present invention. Construction platform 100 has an inboard portion 101 that extends over a floor 102 of building that is under construction. Inboard portion 101 includes two beams 103a, 103b that extend inwards from the edge of floor 102. Beams 103a, 103b are held against floor 102 using two mechanisms. Firstly, there are shoring posts 105a, 105b that extend from the inboard portion 101 to a floor above 107, so that they press inboard ends of beams 103a, 103b against floor 102. Secondly, there are clamp plates 109a, 109b that extend over beams 103a, 103b and the clamp plates 109a, 109b are bolted to floor 102. Thus, construction platform 100 is securely attached to floor 102 in a manner that allows a large mass to be supported on an outboard portion 111 of construction platform 100.

[0016]FIG. 1 shows a large object 113 being lowered by crane onto a landing deck 115 that is part of outboard portion 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com