Collapsible freestanding body armor support stand

a freestanding, article technology, applied in the direction of stands/trestles, dummies, show hangers, etc., can solve the problems of one or more components of the support stand failing, adding to the overall size, complexity and cost of the support stand, and not being particularly robus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

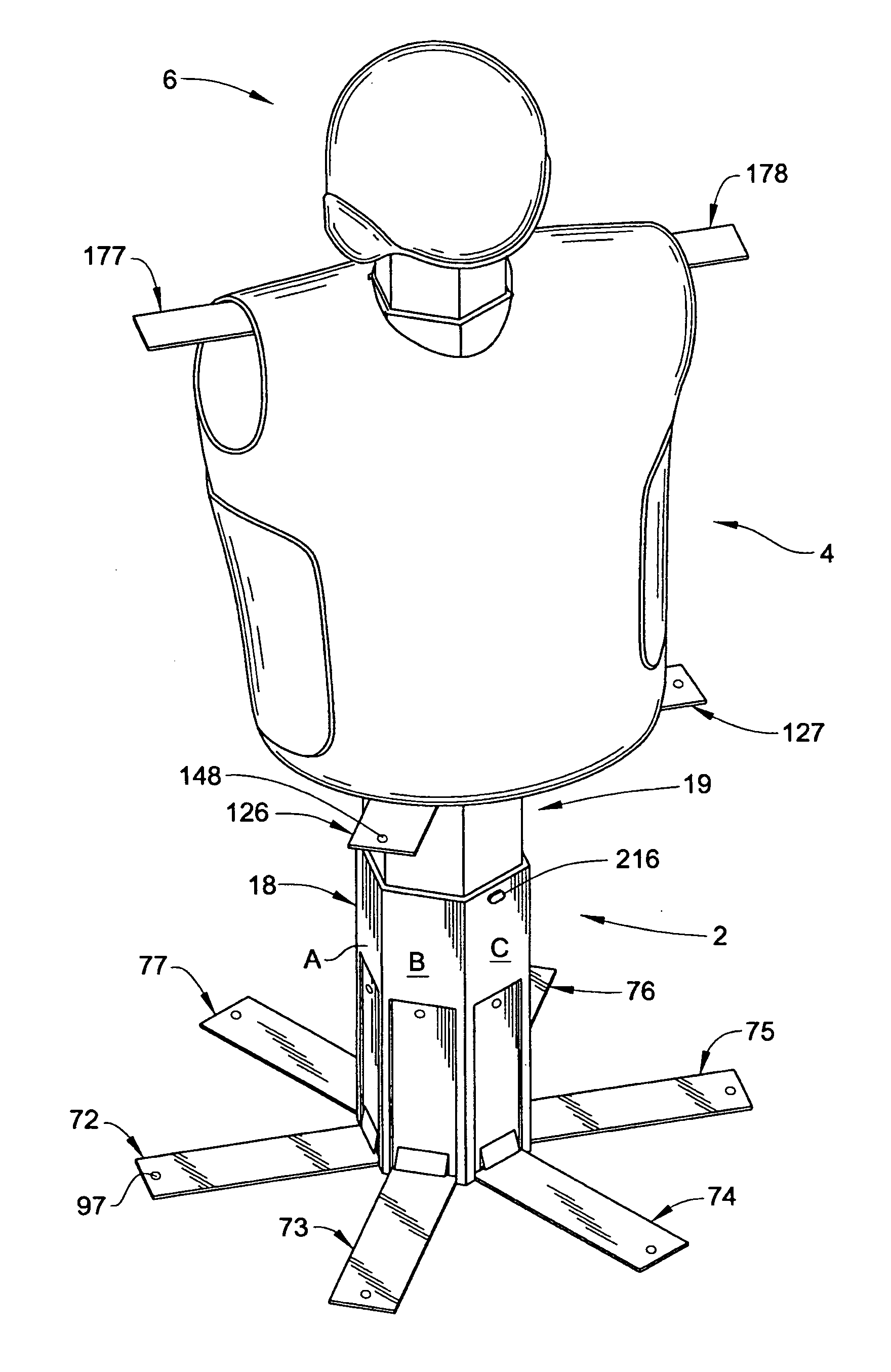

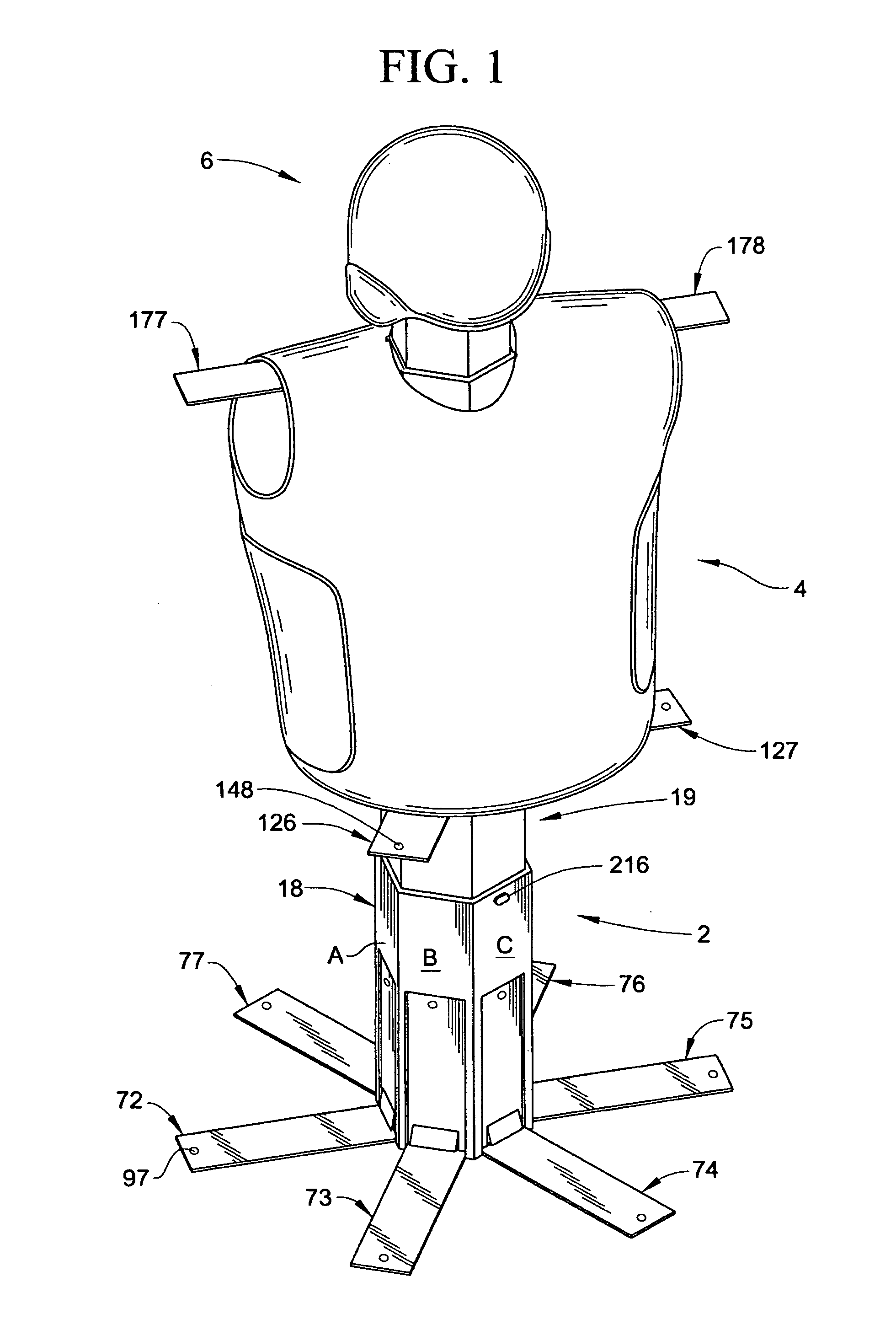

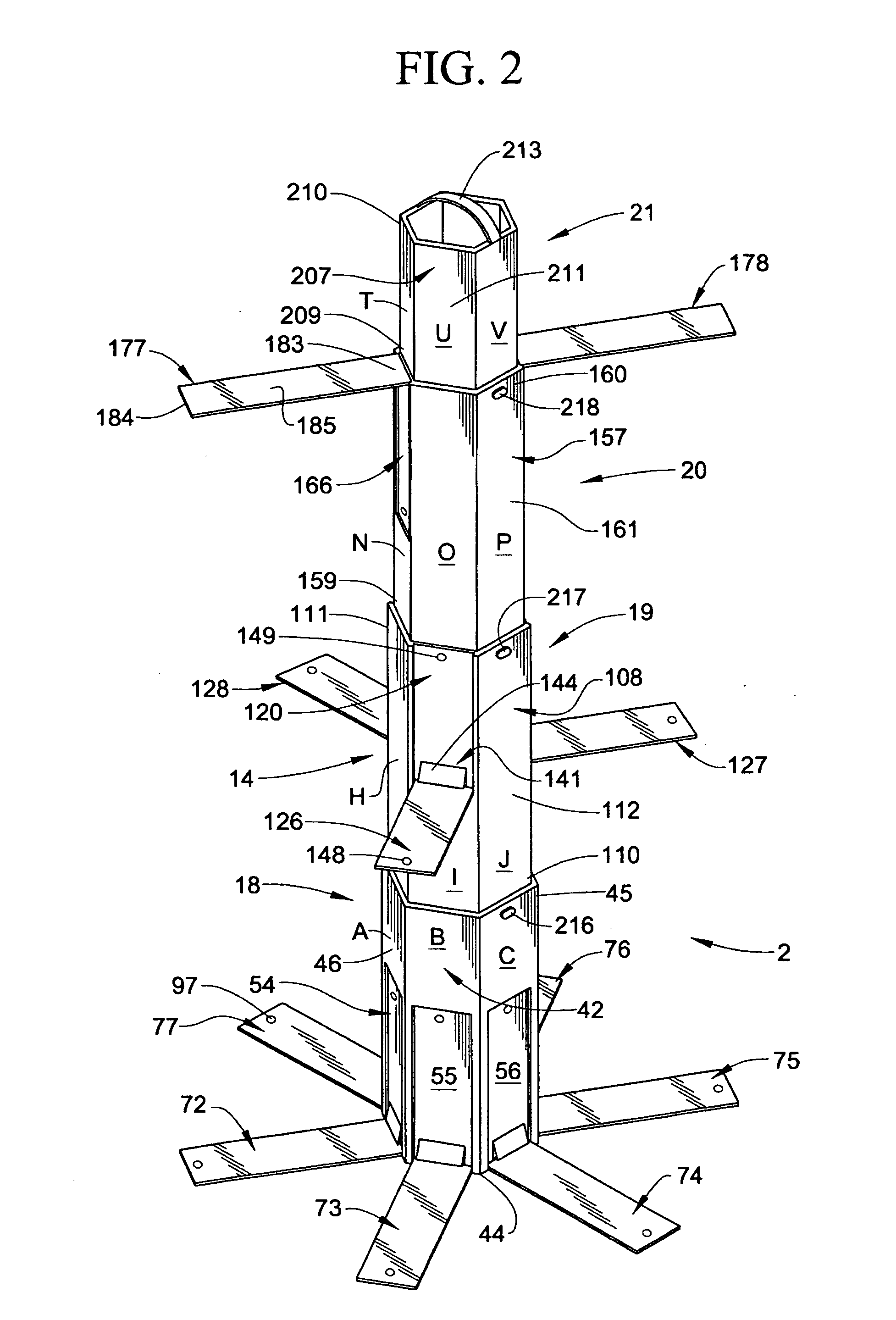

[0021]With initial reference to FIGS. 1 and 2, a collapsible, freestanding body armor support stand constructed in accordance with the present invention is generally indicated at 2. Support stand 2 is shown, in FIG. 1, supporting body armor 4 and a tactical helmet 6. Of course, support stand 2 could support various other items of gear, tactical or otherwise, such as web gear, uniforms, weapons, sunglasses and the like. As best shown in FIG. 2, body armor support stand 2 includes a main support member 14 formed from a plurality of telescoping, multi-faceted support sections. More specifically, main support member 14 includes a first support section 18, a second support section 19, a third support section 20 and a fourth support section 21. In the embodiment shown, each support section 18-21 is hexagonal in shape. However, various geometric shapes would also be acceptable.

[0022]Reference will now be made to FIGS. 2 and 3 in describing first support section 18 constructed in accordance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com