Shoe structure and fabricating method of the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

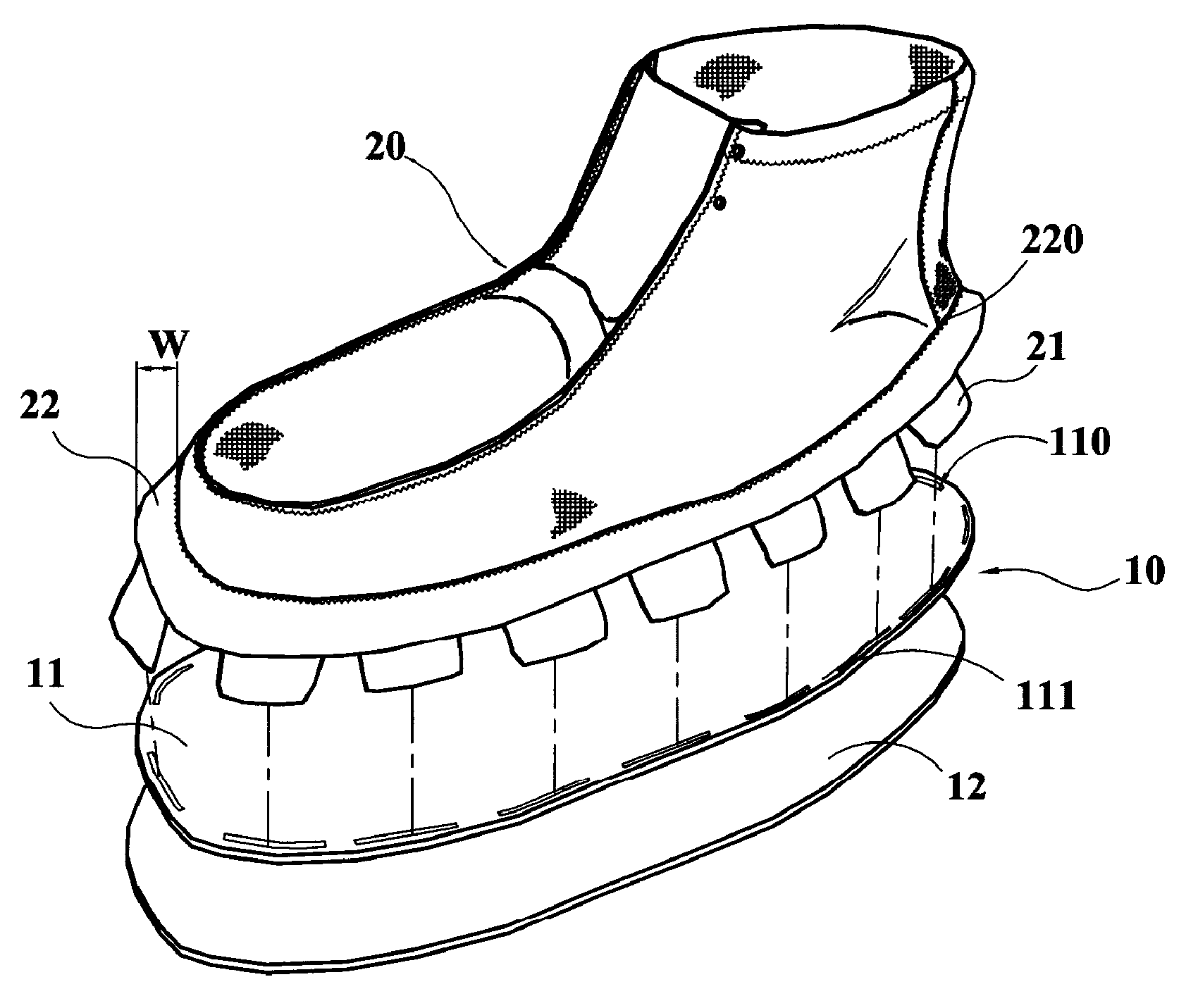

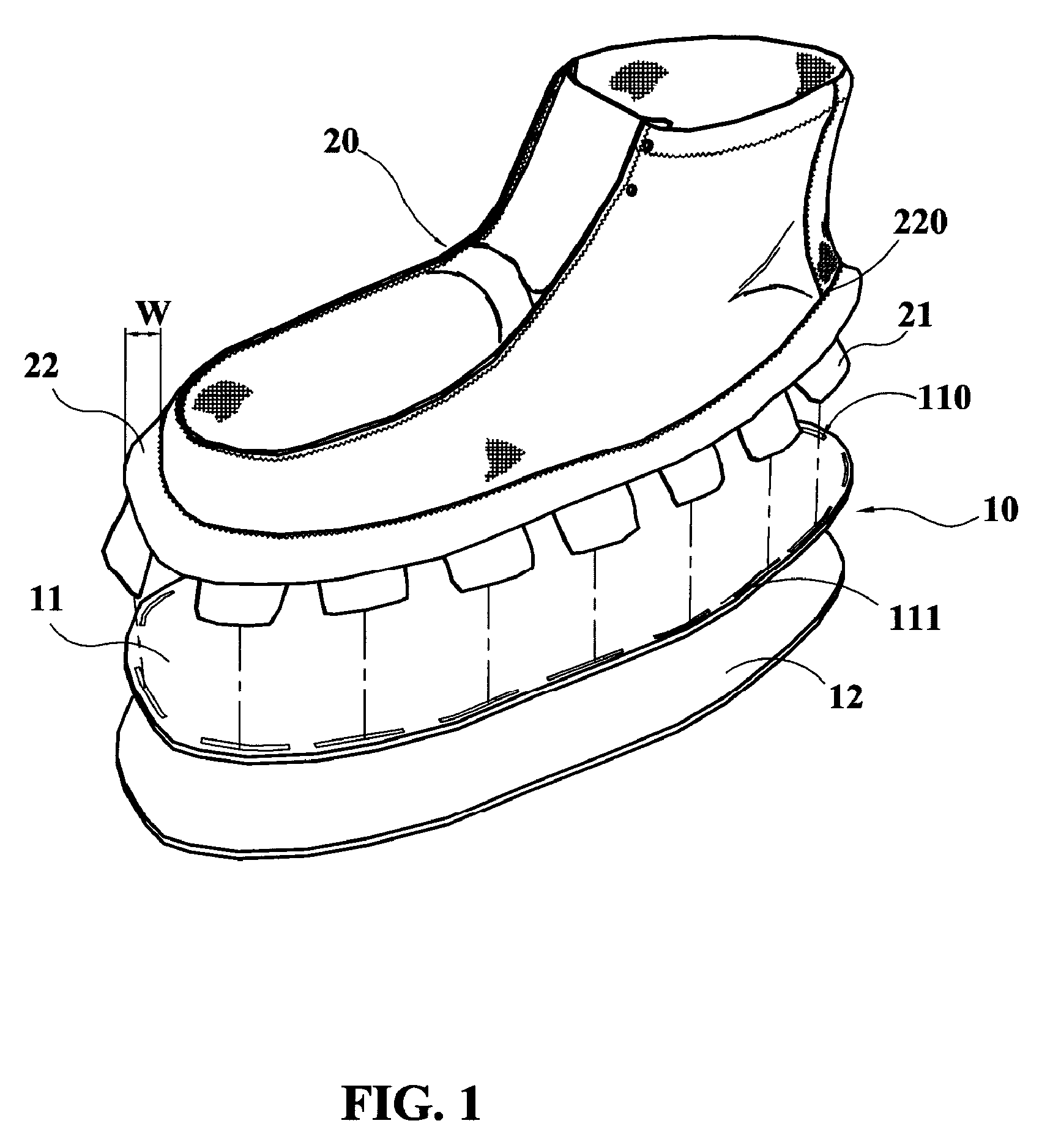

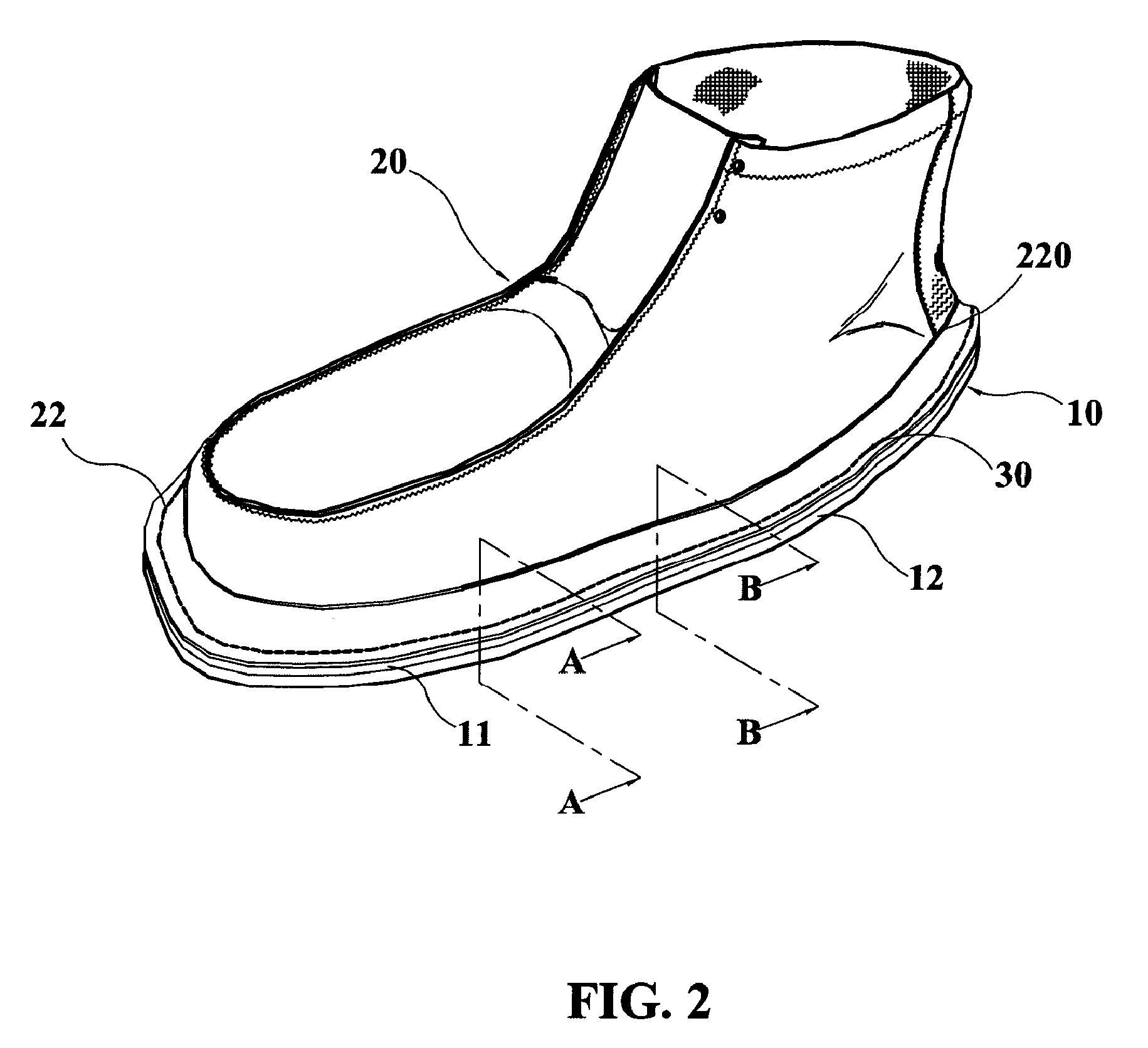

[0027]Referring to FIGS. 1 to 4, a shoe structure embodiment according to the present invention includes a sole 10 and an upper 20. The sole 10 includes at least an insole 11 and an outsole 12. The sole 10 maybe made of leather, plastic foaming material, such as EVA or the like.

[0028]The lower edge of the upper 20 is formed with a plurality of teeth-like extensions 21, and the peripheral edge 111 of the insole 11 is formed with a plurality of edge slits 110 for allowing the teeth-like extensions 21 to pass through thereby to be glued and bonded on the underside of the insole 11.

[0029]The shoe structure may further include a peripheral shielding band 22 which has a width W for connecting to the lower end of the upper portion 20 and the upper side of the peripheral edge 111 of the insole 11 by glue, adhesive and / or stitches 30 and 220 to cover the edge slits 110, so as to avoid rain, water, liquid or the like flowing into the sole 10 via the teeth-like extensions 21 and the edge slits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com