Work seat apparatus

a work seat and seat technology, applied in the field of work seat apparatus, can solve the problem that the operation is not readily performed on the ceiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

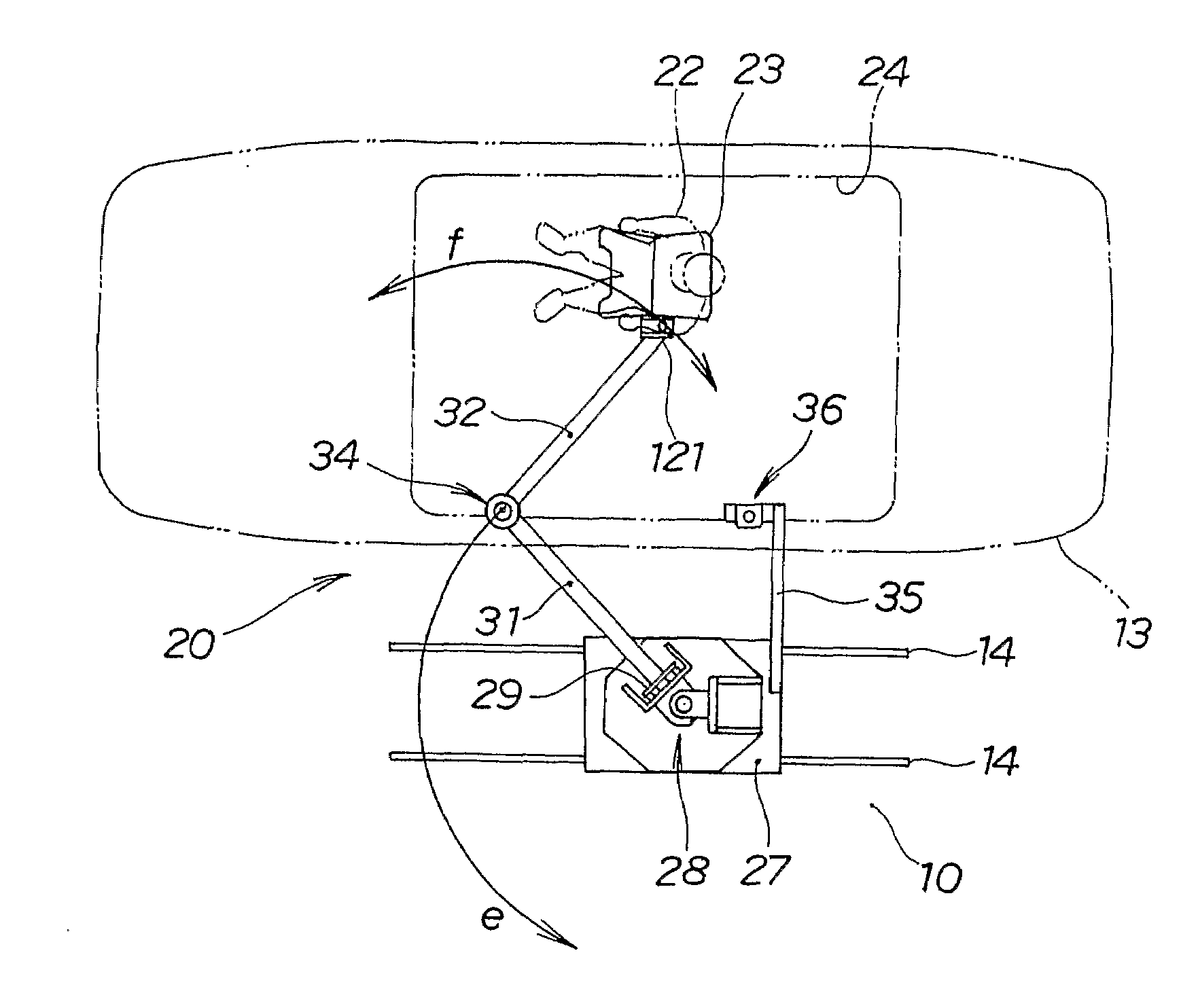

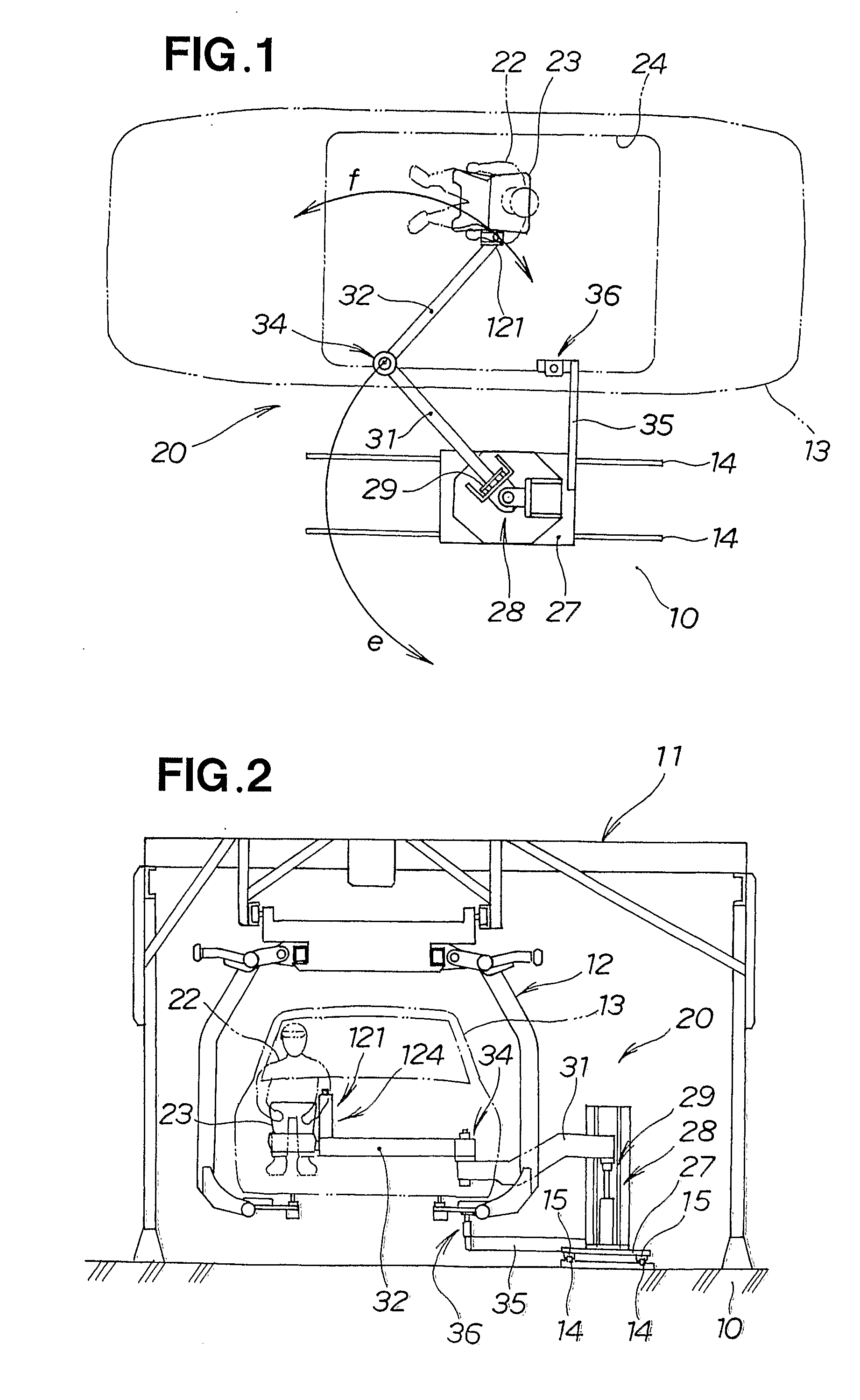

[0043]An overhead conveyer 11 for conveying a vehicle and a conveying hanger 12 that is provided to the overhead conveyer 11 and that is used as a conveying mechanism to convey a vehicle are provided to an automobile assembly line, as shown in FIGS. 1 and 2. A vehicle 13 is mounted on the conveying hanger 12 as a workpiece. In the automobile assembly line, components and the like are attached while the vehicle 13 is moved.

[0044]Rails 14, 14 are disposed to sides of the vehicle 13 along a movement direction of the vehicle 13 above the floor, stage, or other anchoring object 10. A work seat apparatus 20 that is provided for tasks in an interior of the automobile is provided to the rails 14, 14 via wheels 15, 15.

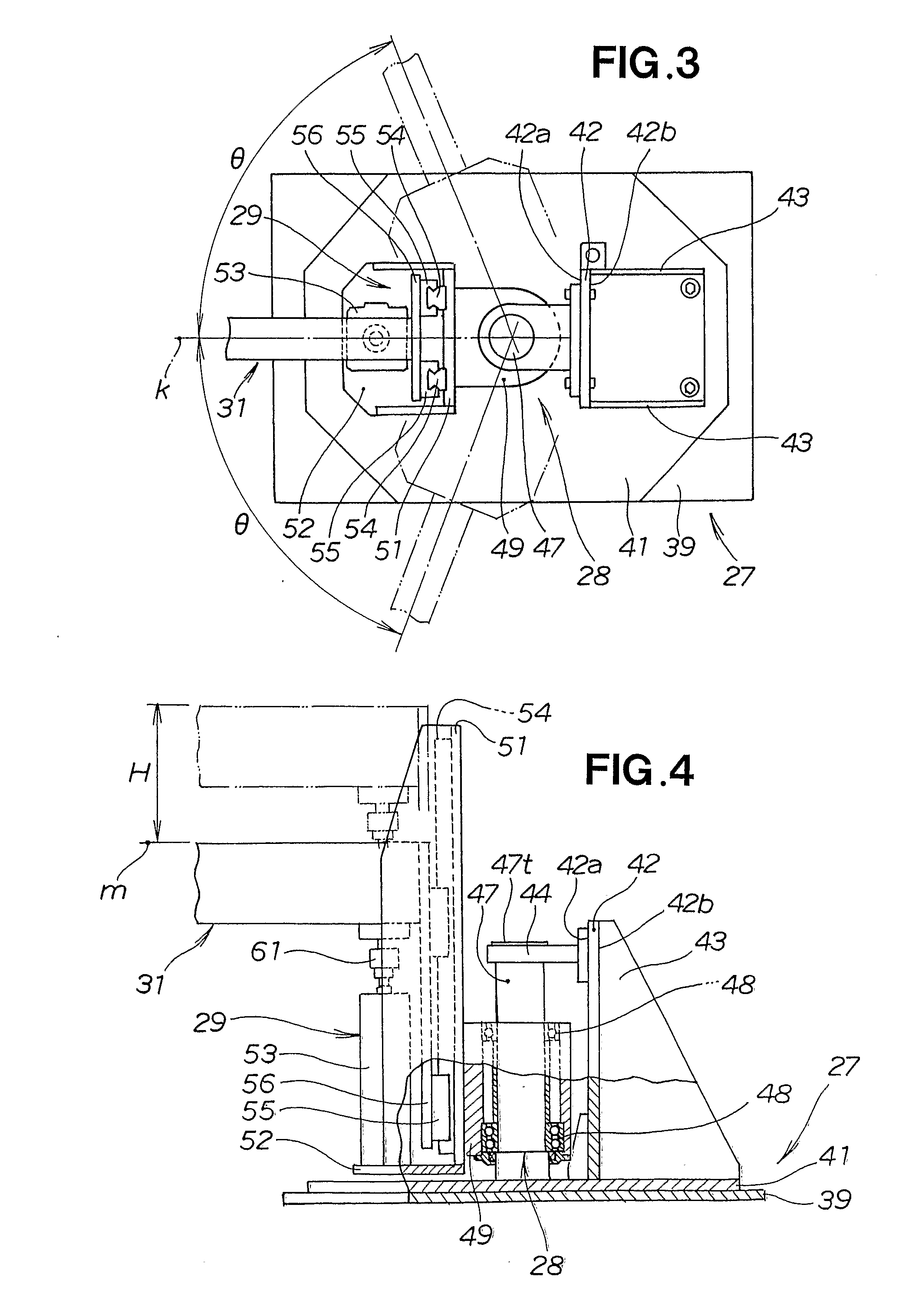

[0045]The work seat apparatus 20 is characterized in comprising a base part 27 provided to an anchoring object 10 in a manner that allows horizontal movement; a rotating support part 28 provided to the base part 27 in a manner that allows rotation about a vertical shaft; a rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com