Press line system and method

a technology of press line and press brake, applied in the field of press line, can solve the problems of press delay, extra wear, wear of motor brakes, etc., and achieve the effect of simple and cheaper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

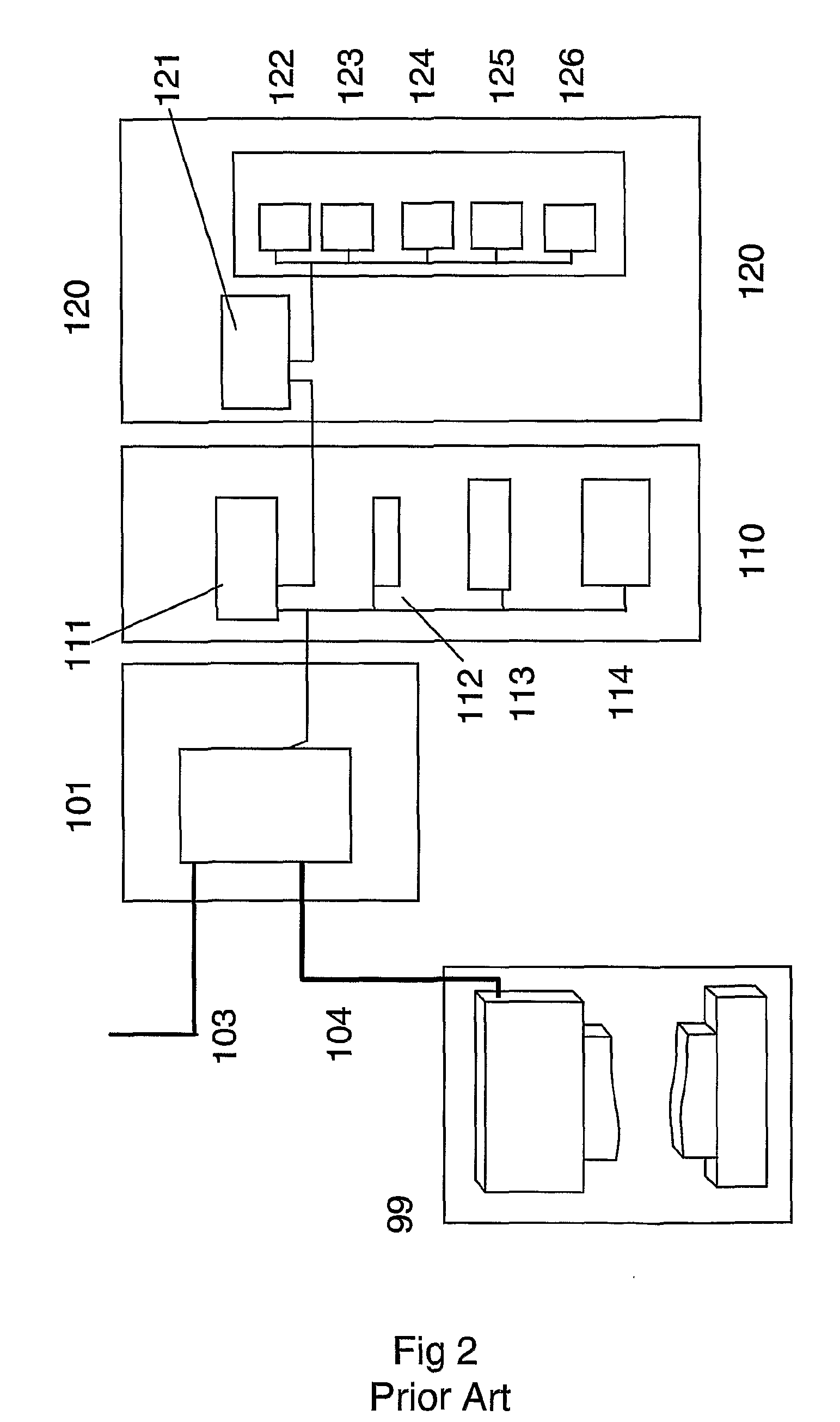

[0063]FIG. 2 shows a press line layout according to the Prior Art, as mentioned above. The layout of this Prior Art arrangement will first be described in order to simplify explanation of the improvements according to the invention. FIG. 2 shows a press 99 arranged with a drive 101 (or electrical drive controller 101) for the main electric drive motor of the press. The motions of the press are controlled by a press controller 110. Press controller 110 comprises a press controller 111 PLC (PLC, Programmable Logic Controller). Press controller 110 controls power to the drive 101, may receive inputs from distributed I / O devices 112, from encoders 113 or sensors and may also be arranged with a press HMI 114 (Human machine interface), ie a press control panel or graphic press control panel.

[0064]A separate controller, press safety controller 120 is arranged connected to all the press safety switches, and emergency stop switches arranged on and around the press. The press safety controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com