Residential fireplace insert system improvements

a technology for insert systems and fireplaces, applied in the field of improvements to the system of residence fireplace inserts, can solve the problems of drying out carbon dust particles up the chimney, all models “leak” air volumes into the combustion chamber without real heat or fuel consumption control, and achieve the effect of sufficient room heating and suitable consistant oxygen burning ratio for consuming fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

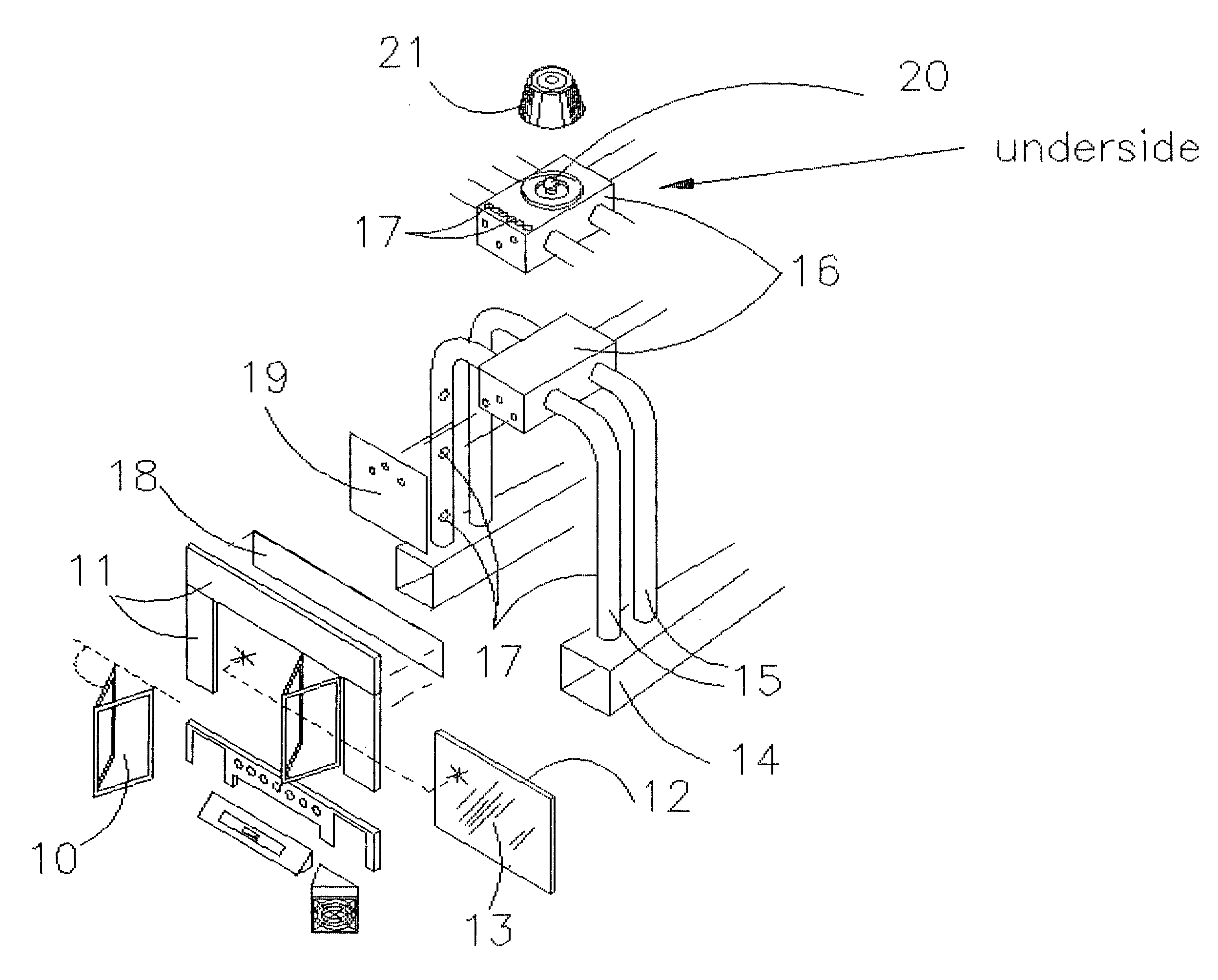

[0010]FIG. 1 is a plan top view identifying manifold 16.

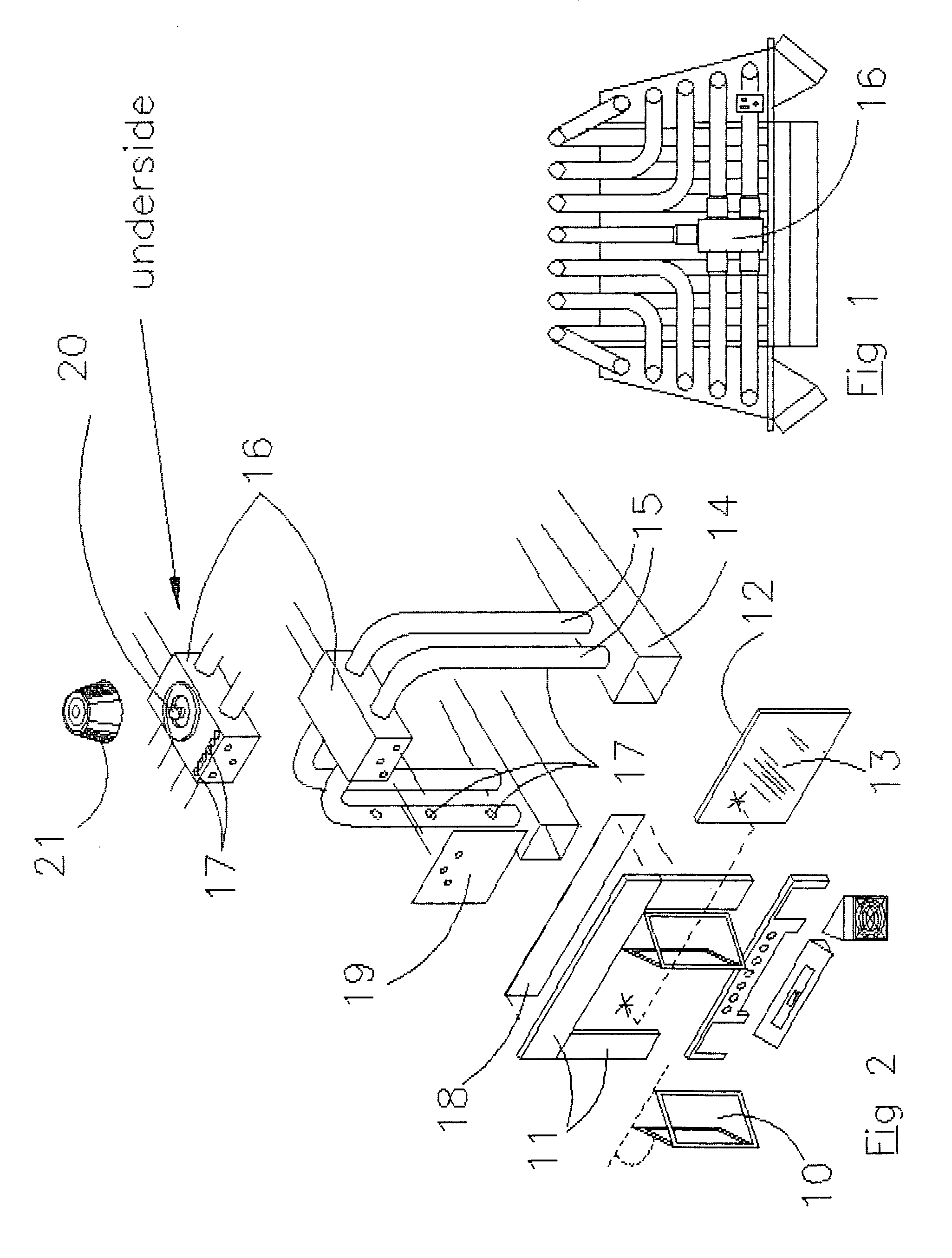

[0011]FIG. 2 is an exploded front quarter-view of the fireplace insert FIG. 1. The hinged door closures 10 are mounted onto the surround 11 in a customary way and can be completely opened wide as indicated. A thin rigid metal frame 12, on which a temperature-tolerant plastic film 13, is stretched and mounted has nearly the same overall dimensions as the said hinged door closures 10 and is able to be stored behind the closed said door closures 10. Attached to the back side of the said surround 11 is a soot deflector 18, a narrow, thin-gage panel of metal

attached to shield the top three or four inches of the said surround 11 opening from soot accumulation. The said soot deflector 18 and deflector 19 help generate a “swirling” air purging action with assistance from a plurality of small openings called air purges 17. These said air purge holes 17 are especially located in the tubular means 15 which contain moving columns of air un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap