Sock and process for the production thereof

a technology for socks and sock soles, applied in the field of socks, can solve the problems of insufficient slip prevention effect, slipping of the heel side of the elastic welt of an ankle-length sock, and discomfort while wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

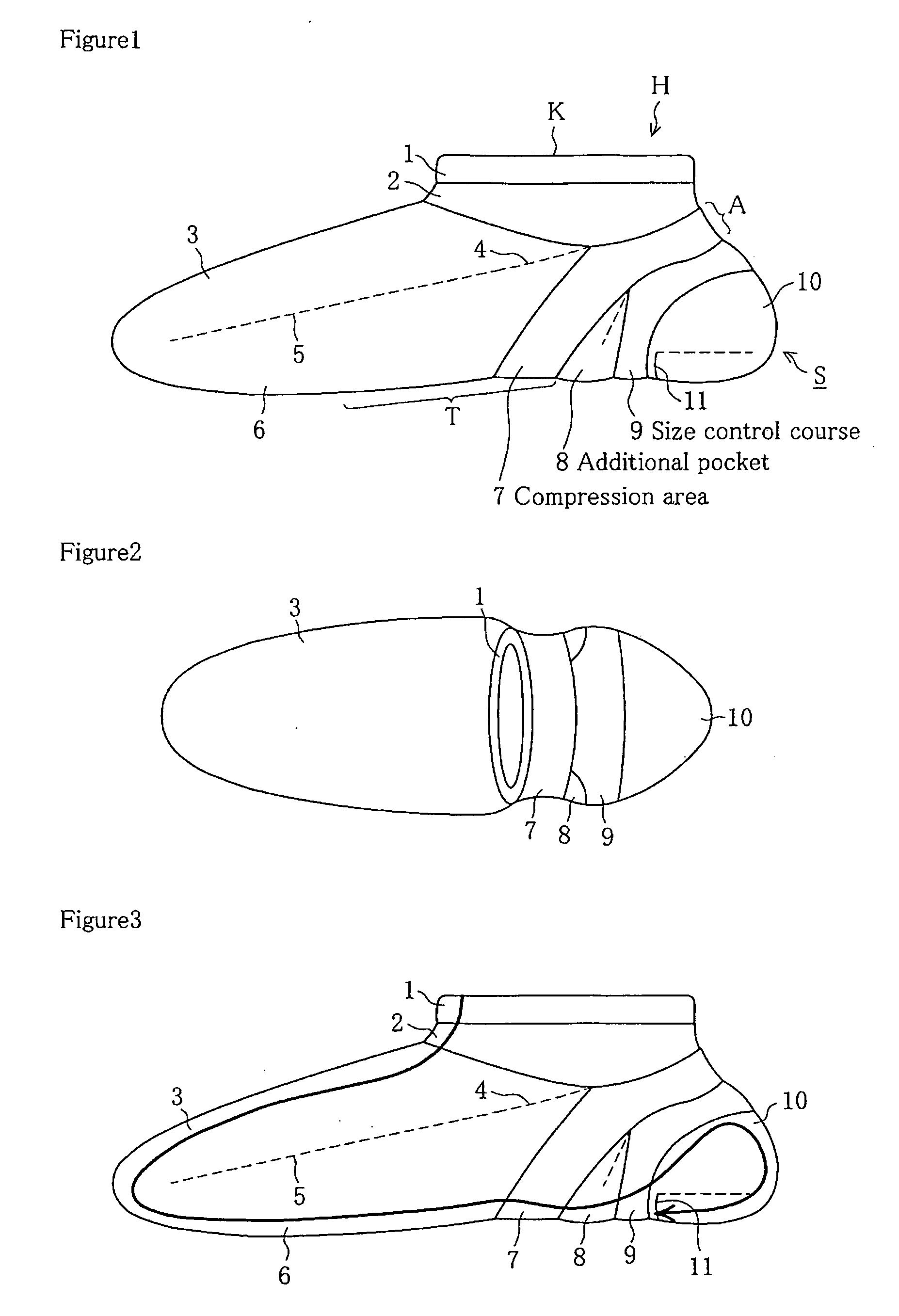

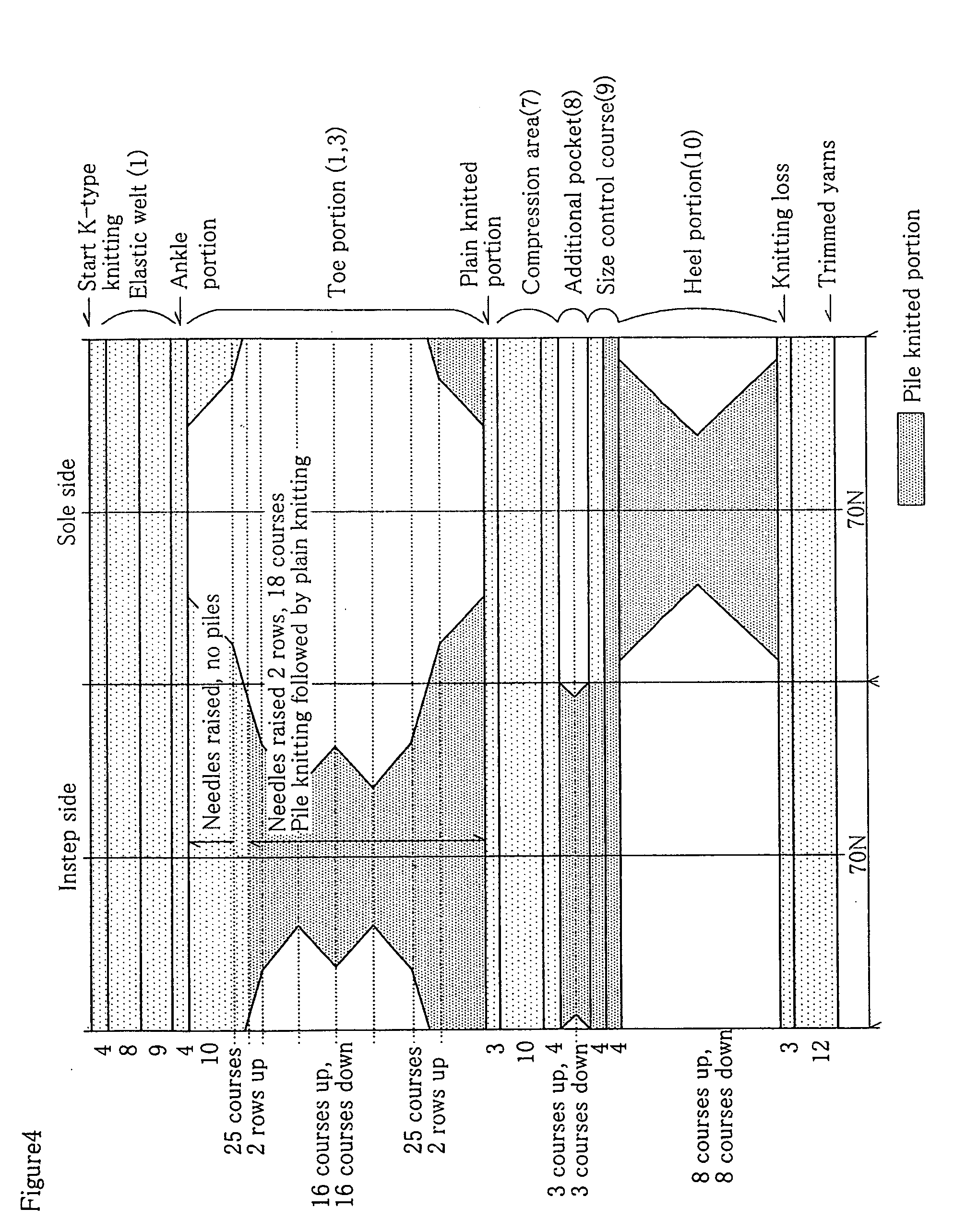

[0041]The sock of the present invention is now explained in further detail on the basis of examples. FIG. 1 is a drawing illustrating a sock of the present invention viewed from the side.

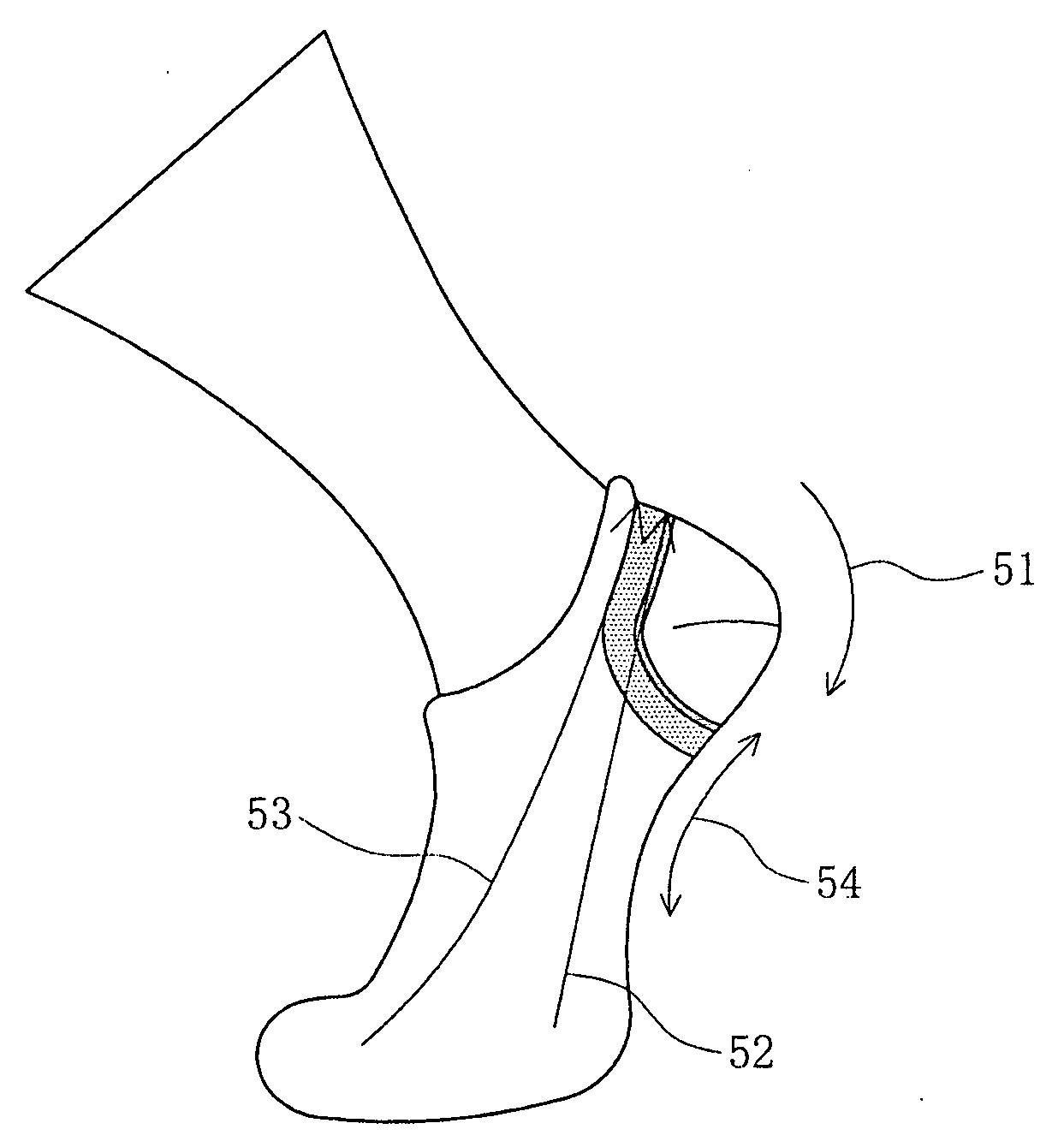

[0042]Sock S of this example is an ankle-length sock with a sock opening H and an opening welt K positioned in the vicinity of the ankle of the wearer. An elastic welt 1, which suitably tightens around the periphery of the ankle due to rubber yarns embedded in knitted ground yarns, is knitted into the opening welt K.

[0043]Reference Numeral 2 is an ankle portion, and in the ankle-length sock of this example, the vertical length thereof is extremely short.

[0044]The most characteristic feature of the present invention is that a compression area 7 with high elasticity and high compressive force is disposed in an area extending from behind an arch portion T to an Achilles tendon portion A above a heel portion 10 in a diagonal direction from the lower left to the upper right, when the sock S is viewed fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com