Clamp for plural wire harnesses

a technology of wire harnesses and clamps, applied in the field of clamps, can solve the problem of low cost of each clamping devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

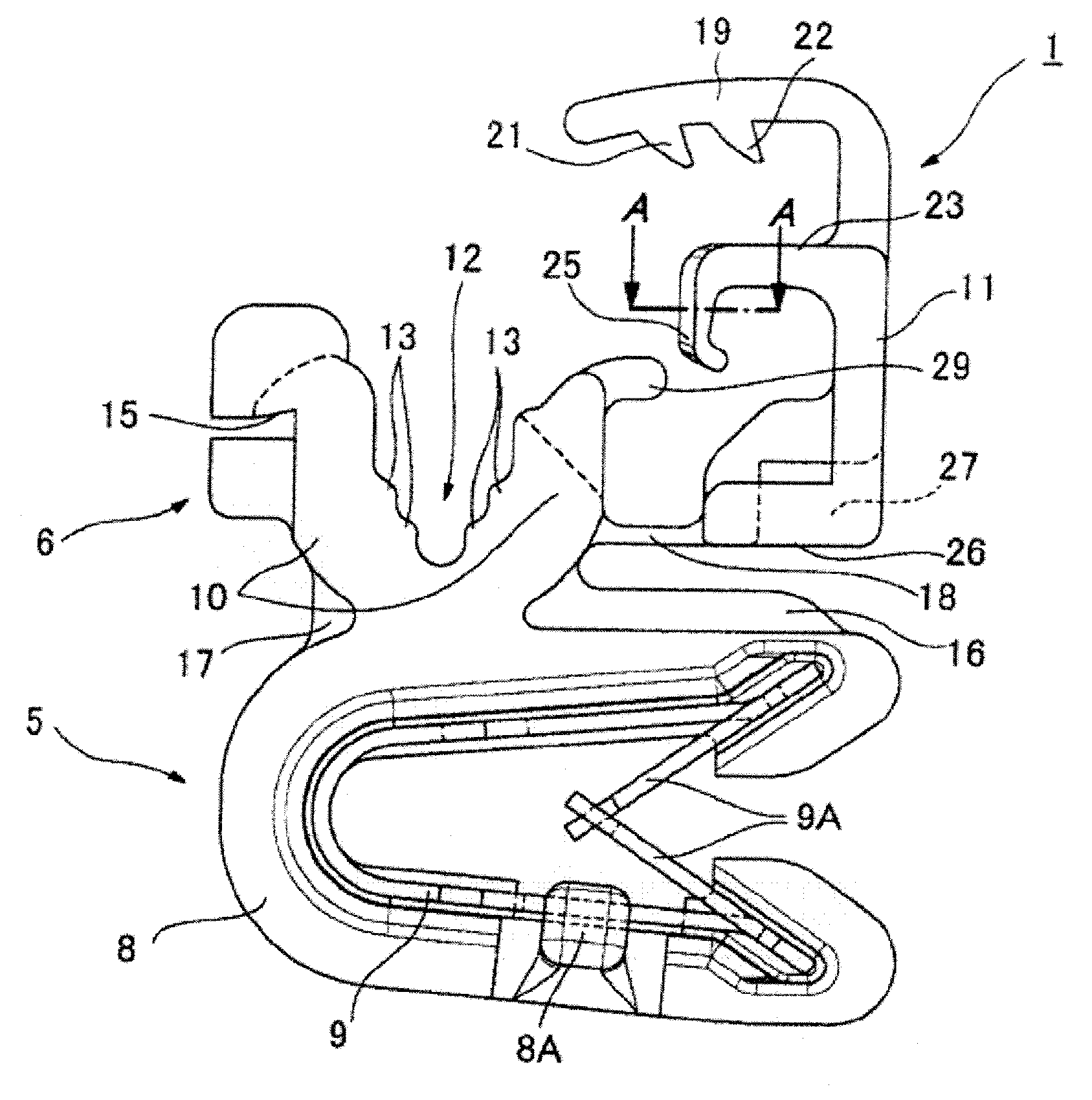

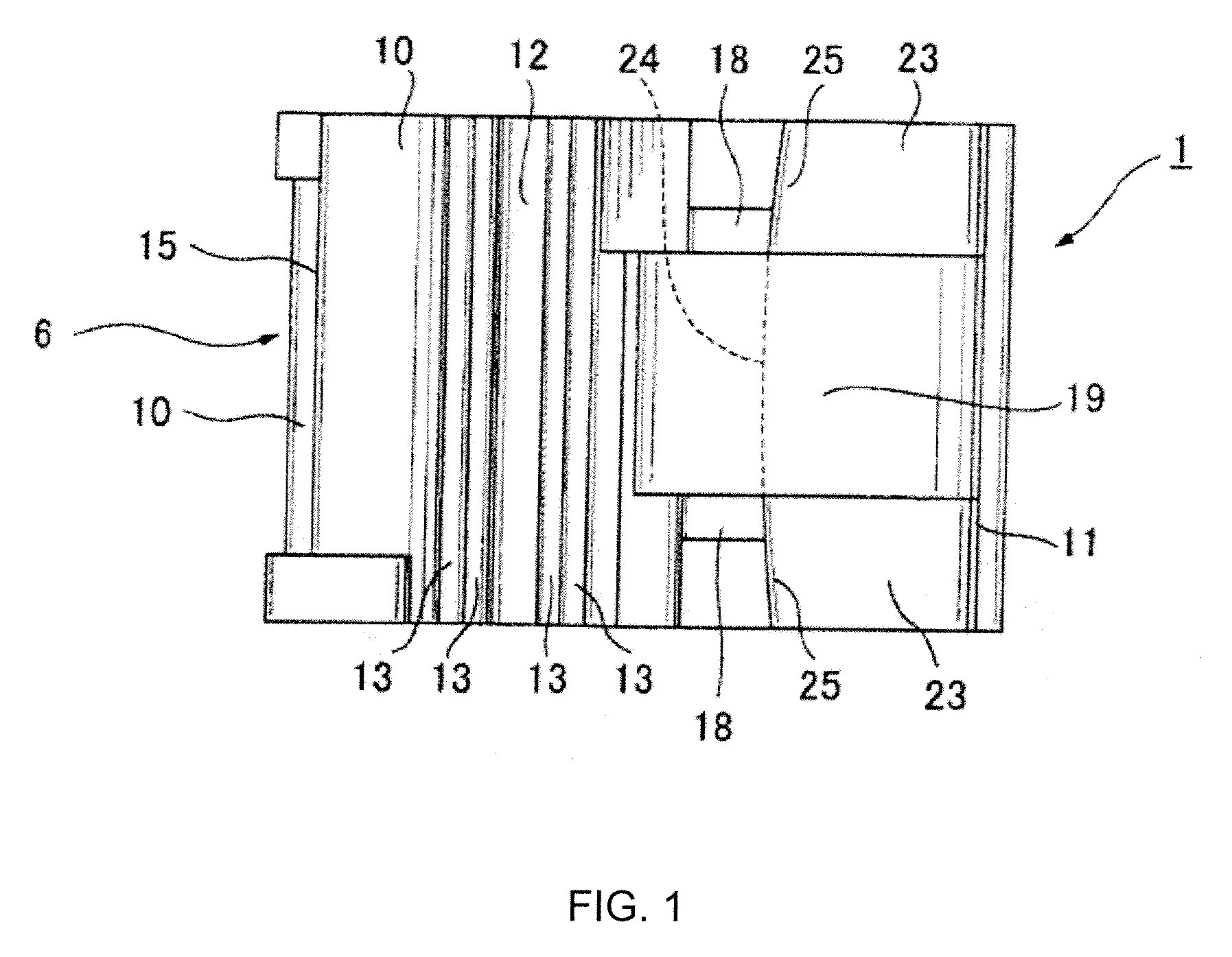

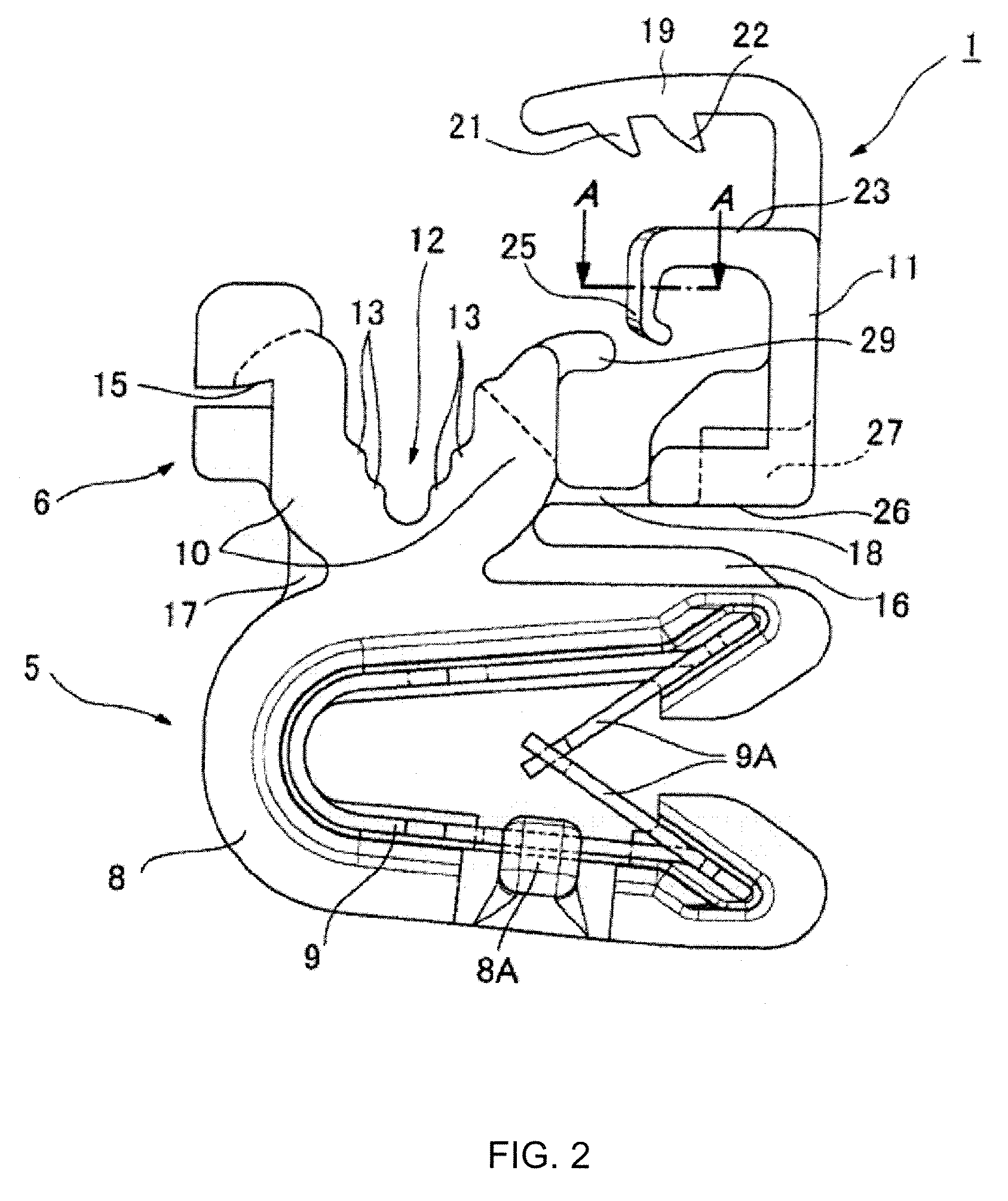

[0024]The following is an explanation with reference to the figures of the clip for a plurality of wire harnesses in an exemplary embodiment of the present invention. FIG. 1, FIG. 2 and FIG. 3 are a plan view, front view and side view of the clamp 1, and FIG. 4 is a cross-sectional view of the clamp 1 from A-A in FIG. 2. The entire clamp 1 is integrally molded using a hard plastic except for the metal holding tab 9 in the panel fixing portion 5. The metal holding tab 9 is connected to the panel fixing portion 5. In FIG. 5, three wire harnesses 3 are attached to a panel 2 mounting component using the clip 1. In FIG. 6, six wire harnesses 3 are held in the clip 1.

[0025]The following is an explanation of the configuration of the clip 1 with reference to FIG. 1 through FIG. 4. The clip 1 comprises a panel fixing portion 5 and a wire harness holding portion 6. The panel fixing portion 5, as shown in FIG. 5, holds a plate-shaped mounting portion 7 standing erect from the panel 2. In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com