Internal assembly for a faucet

a technology for internal assembly and faucets, which is applied in the direction of water supply installation, transportation and packaging, mechanical equipment, etc., can solve the problems of compromising durability and installation of cartridges, affecting the performance of conventional single-handle water faucets, and affecting the durability and cost of manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

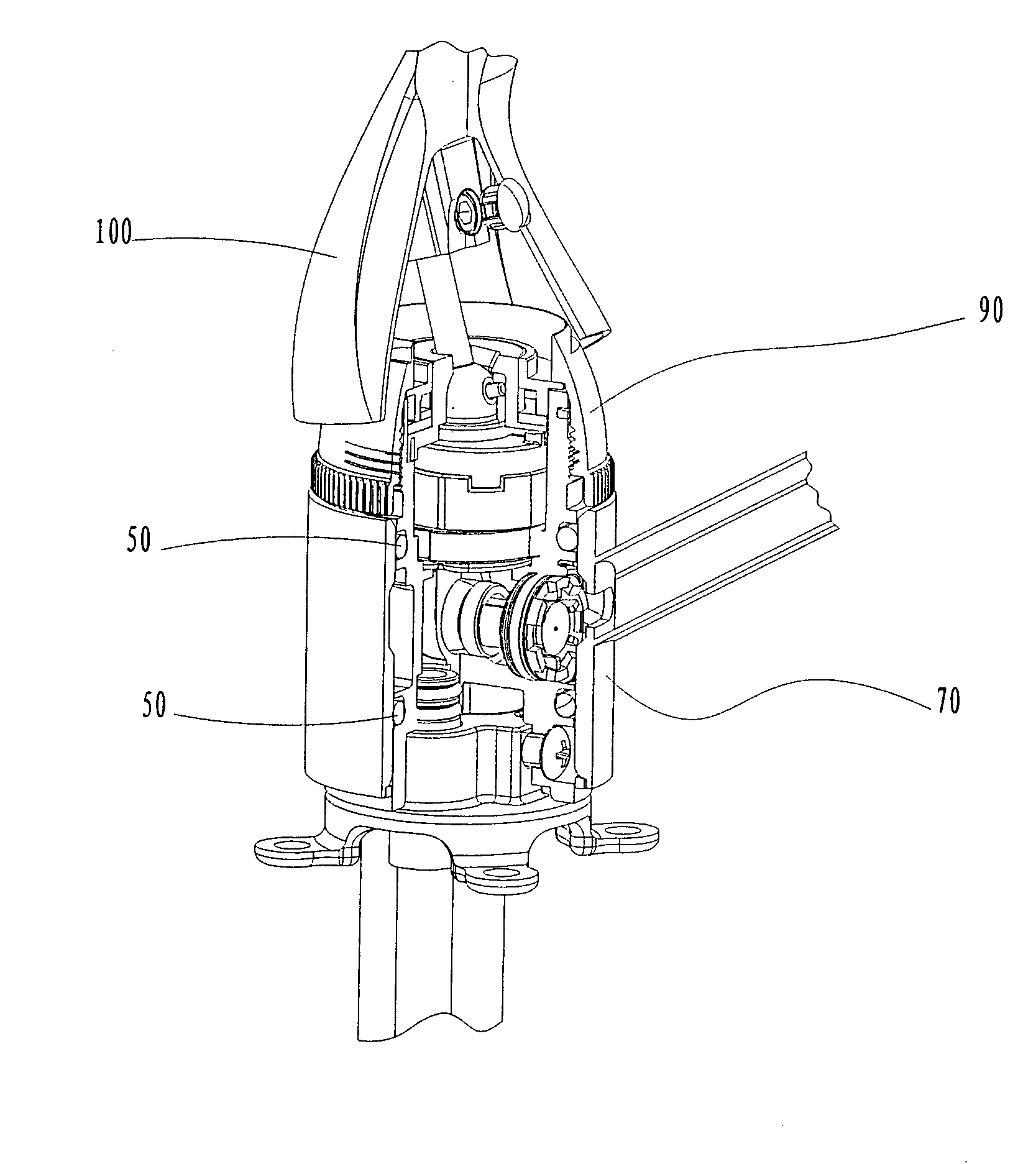

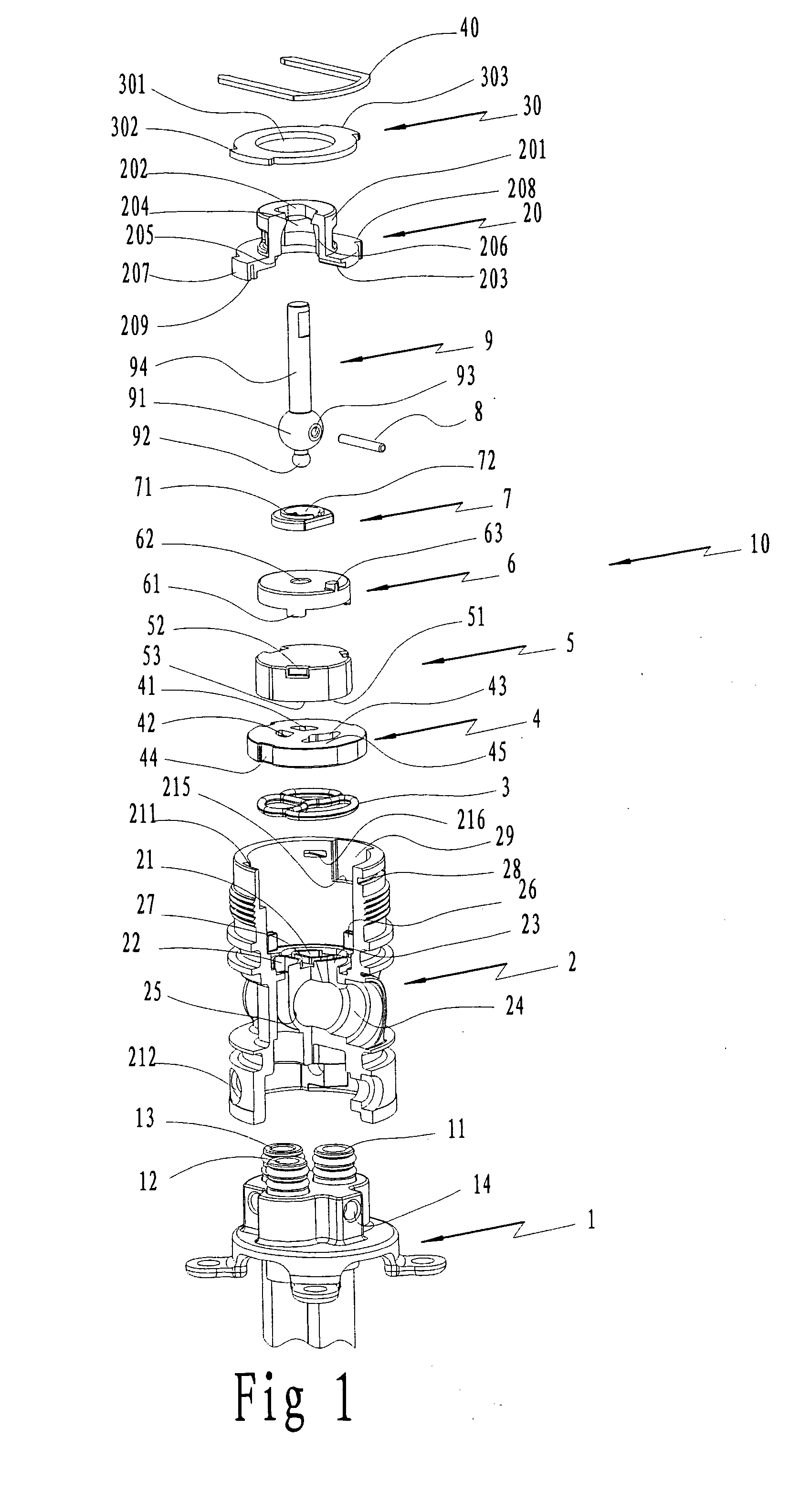

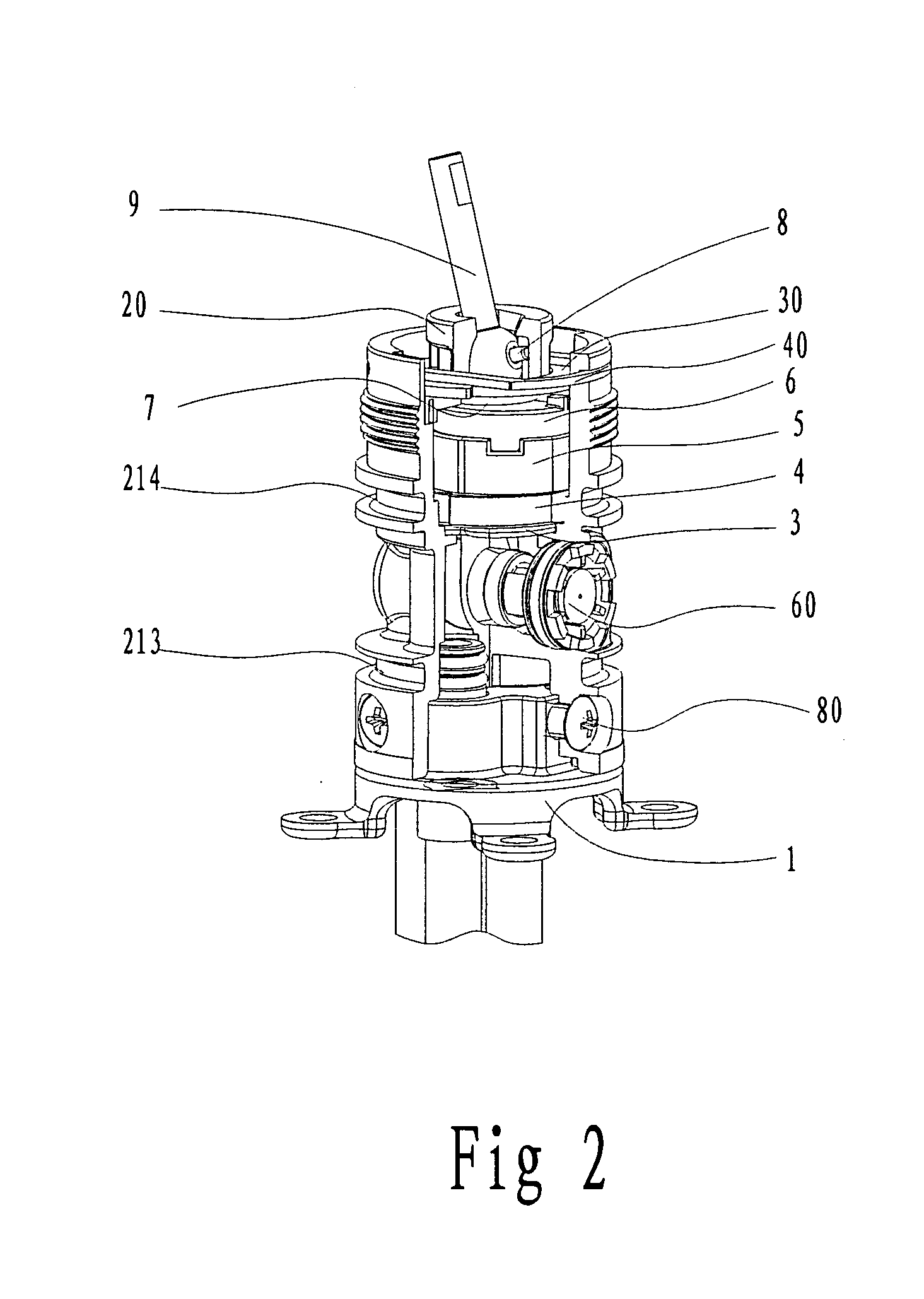

[0019]FIG. 1 depicts one embodiment of an internal assembly 10 for a faucet of the present invention. The internal assembly 10 includes an independent base 1, a main body 2, a sealing element 3, a lower disk 4, an intermediate disk 5, an upper disk 6, a fixing element 7, a post 8, a joystick 9, a seat 20, an annulus 30, and a retaining U-ring 40.

[0020]A cold water inlet 11, a hot water inlet 12 and a water discharge line 13 may be connected to the independent base 1. The sidewall of independent base 1 includes at least one screw hole 14.

[0021]The main body 2 includes a cold water inlet hole 21, a hot water inlet hole 22, a mixed water outlet hole 23, a spout discharge hole 25, and optionally, a hole 24 for installing a change valve 60.

[0022]The inner wall of the main body 2 includes projections 26. A groove 27 is located around the cold water inlet hole 21, hot water inlet hole 22, and mixed water outlet hole 23. Groove 27 receives sealing element 3.

[0023]The top wall of the main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com