Physiologically harmonized tricuspid annuloplasty ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

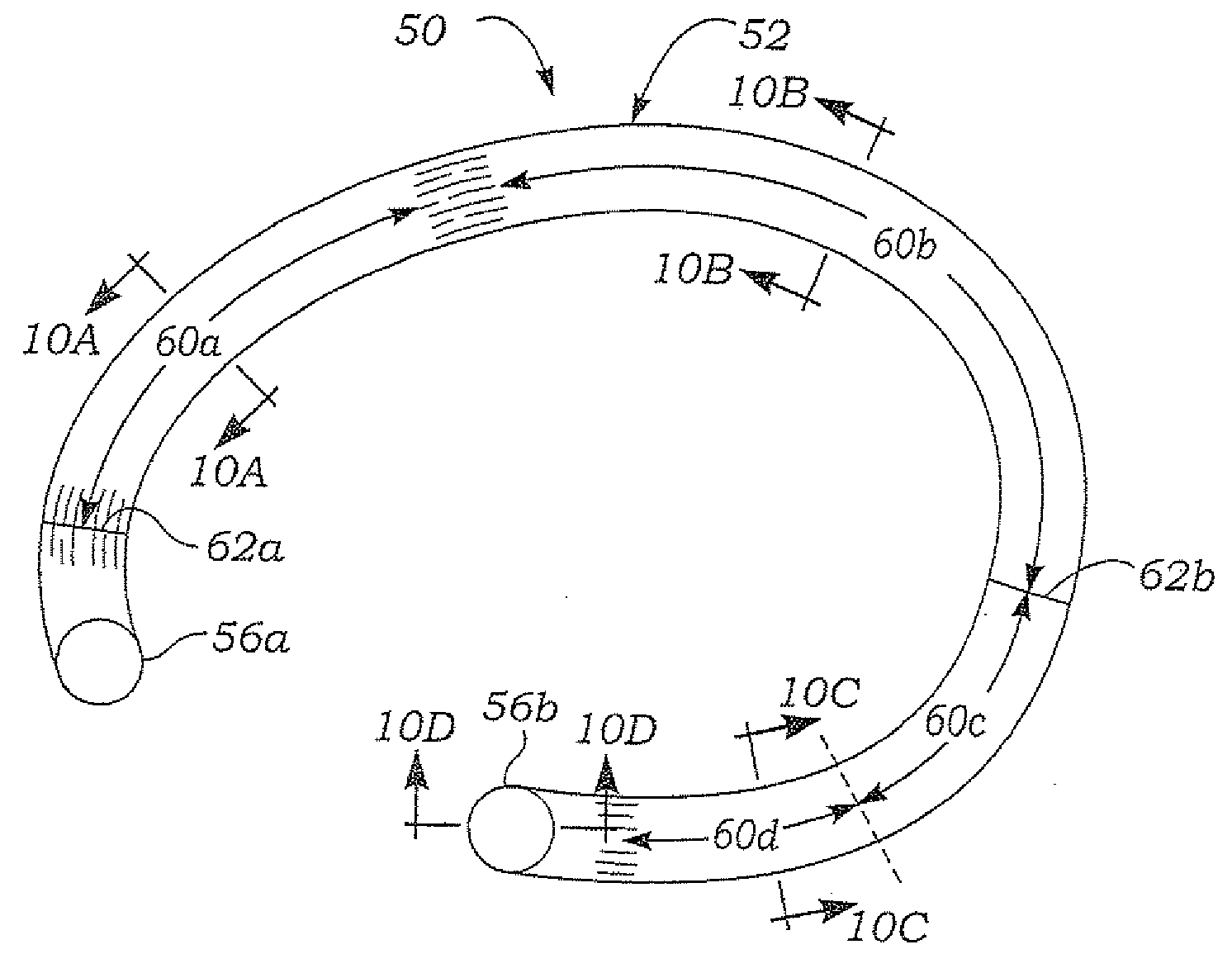

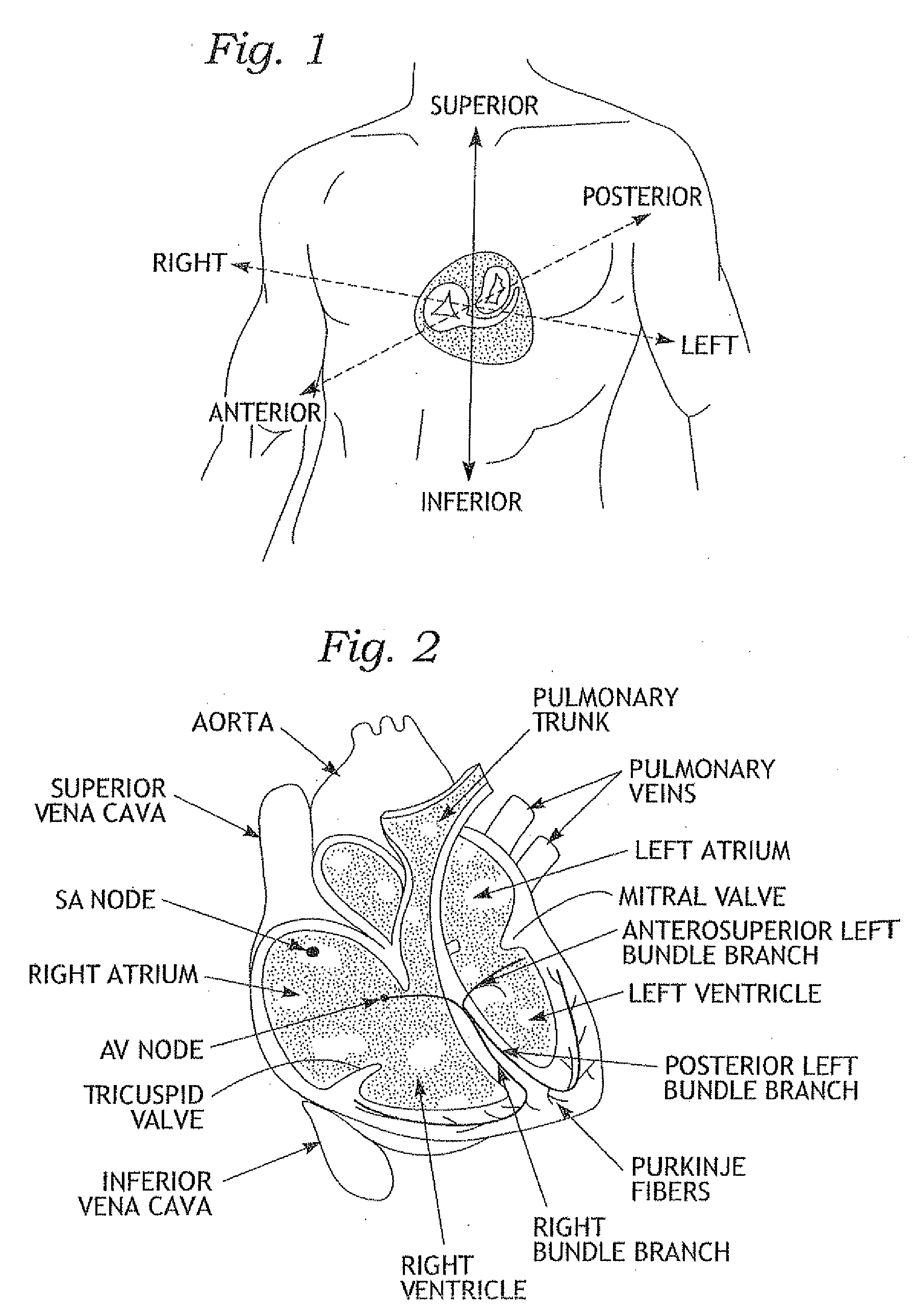

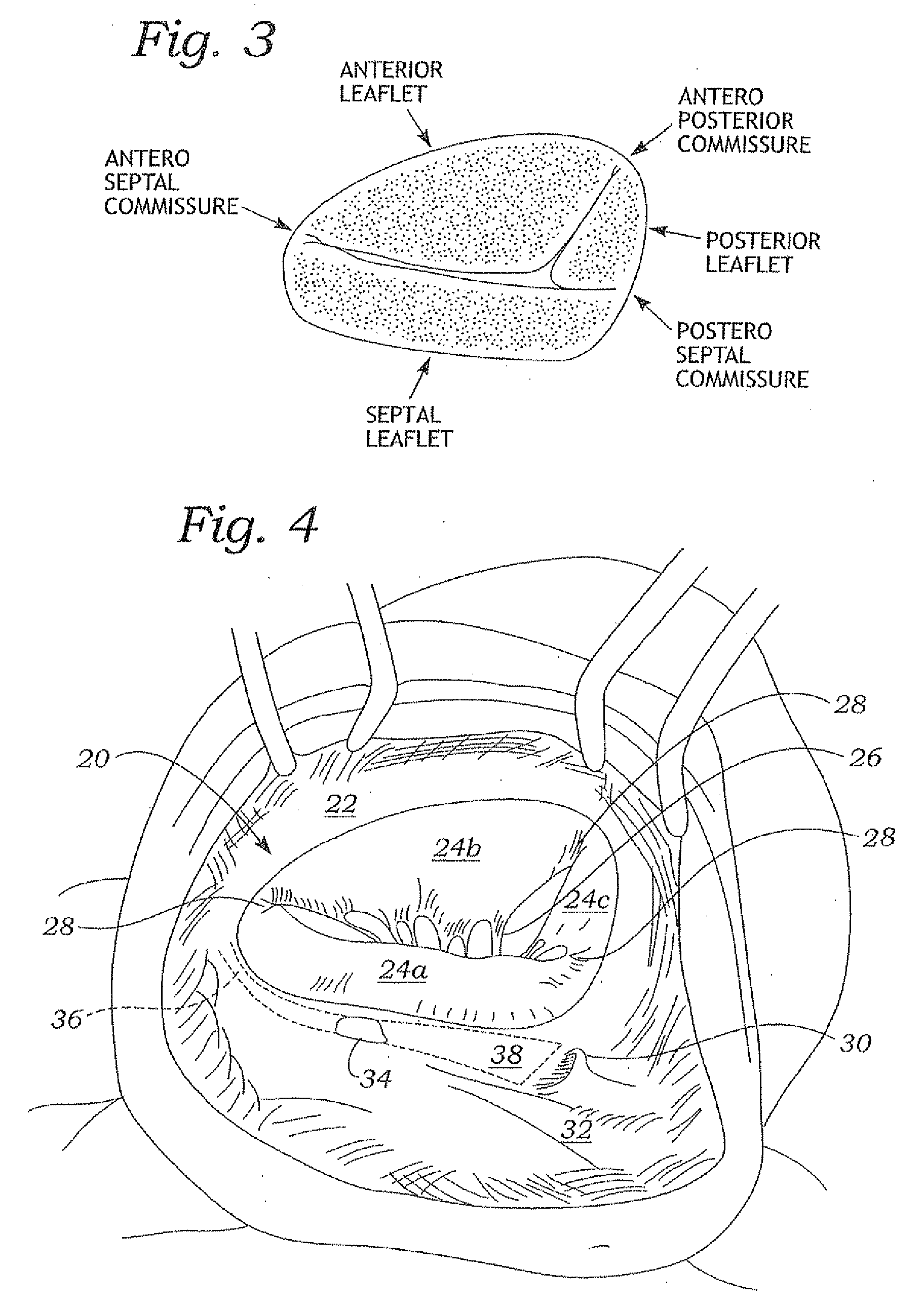

[0038]The present invention provides an improved tricuspid annuloplasty ring that better conforms to the native annulus and is shaped to protect certain features of the surrounding anatomy. The ring of the present invention is designed to support a majority of the tricuspid annulus without risking injury to the leaflet tissue and heart's conductive system, such as the AV node 34 and bundle of His 36 (see FIG. 4). Additionally, the present ring is contoured to better approximate the three-dimensional shape of the tricuspid annulus; specifically, the ring is substantially planar but includes a bulge in the inflow direction at the location of the bulge created by the adjacent aorta. The bulge helps reduce stress between the ring and surrounding tissue, and thus the potential for tearing or ring dehiscence.

[0039]Another feature that matches the present tricuspid ring with the physiological features of the annulus is a variable flexibility from a relatively stiff first segment to a relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com