Structural insulated panel system including junctures

a technology of structural insulation and panel system, applied in the direction of building roofs, building components, pillars, etc., can solve problems such as complex construction and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

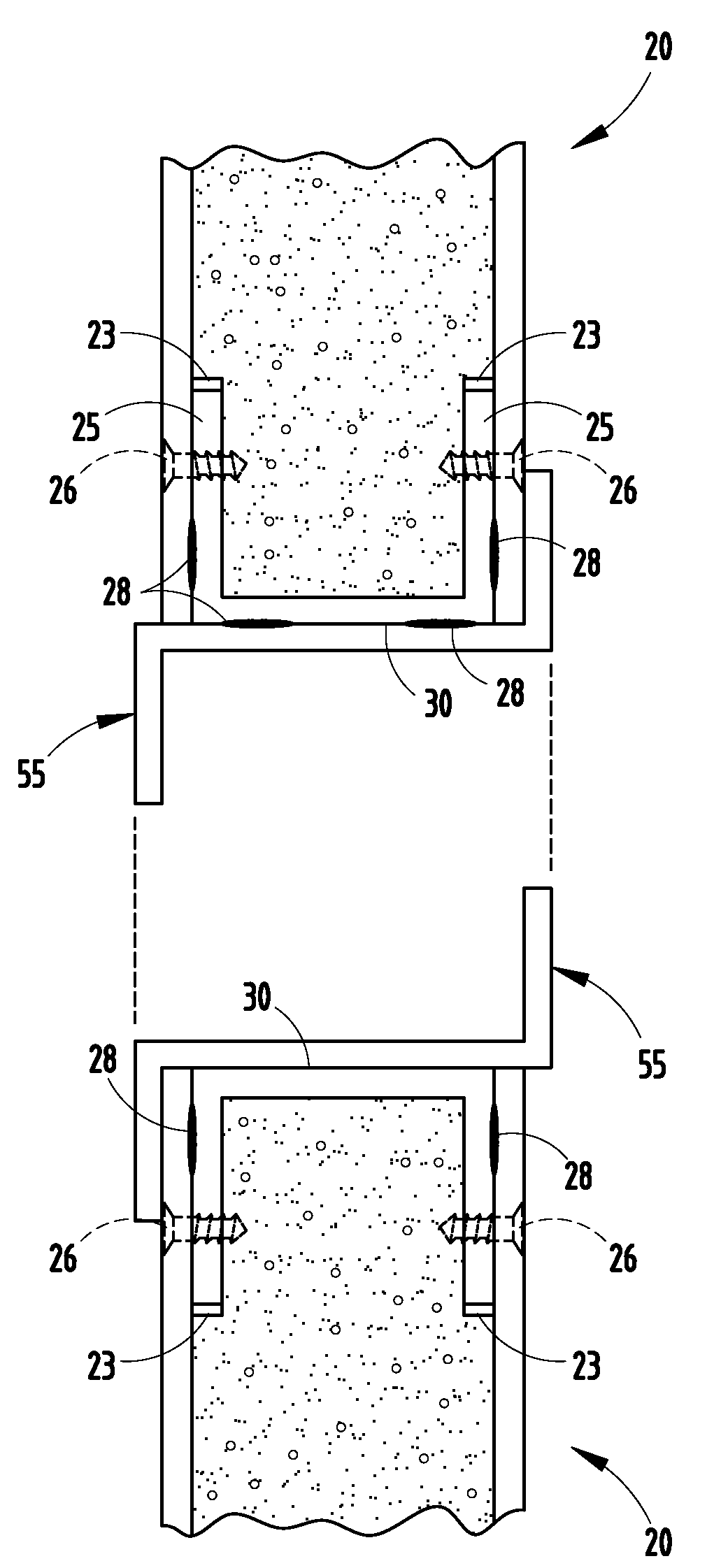

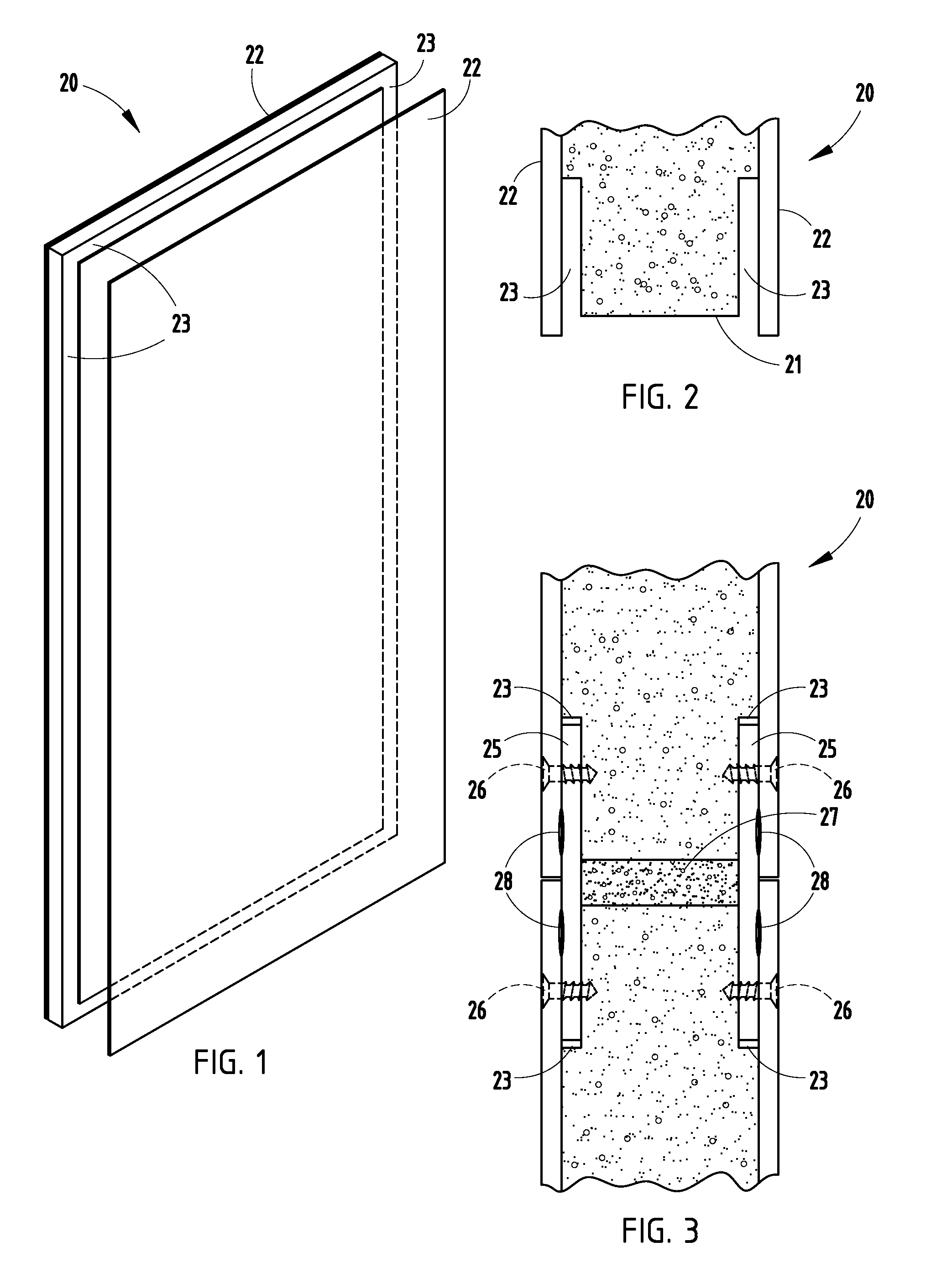

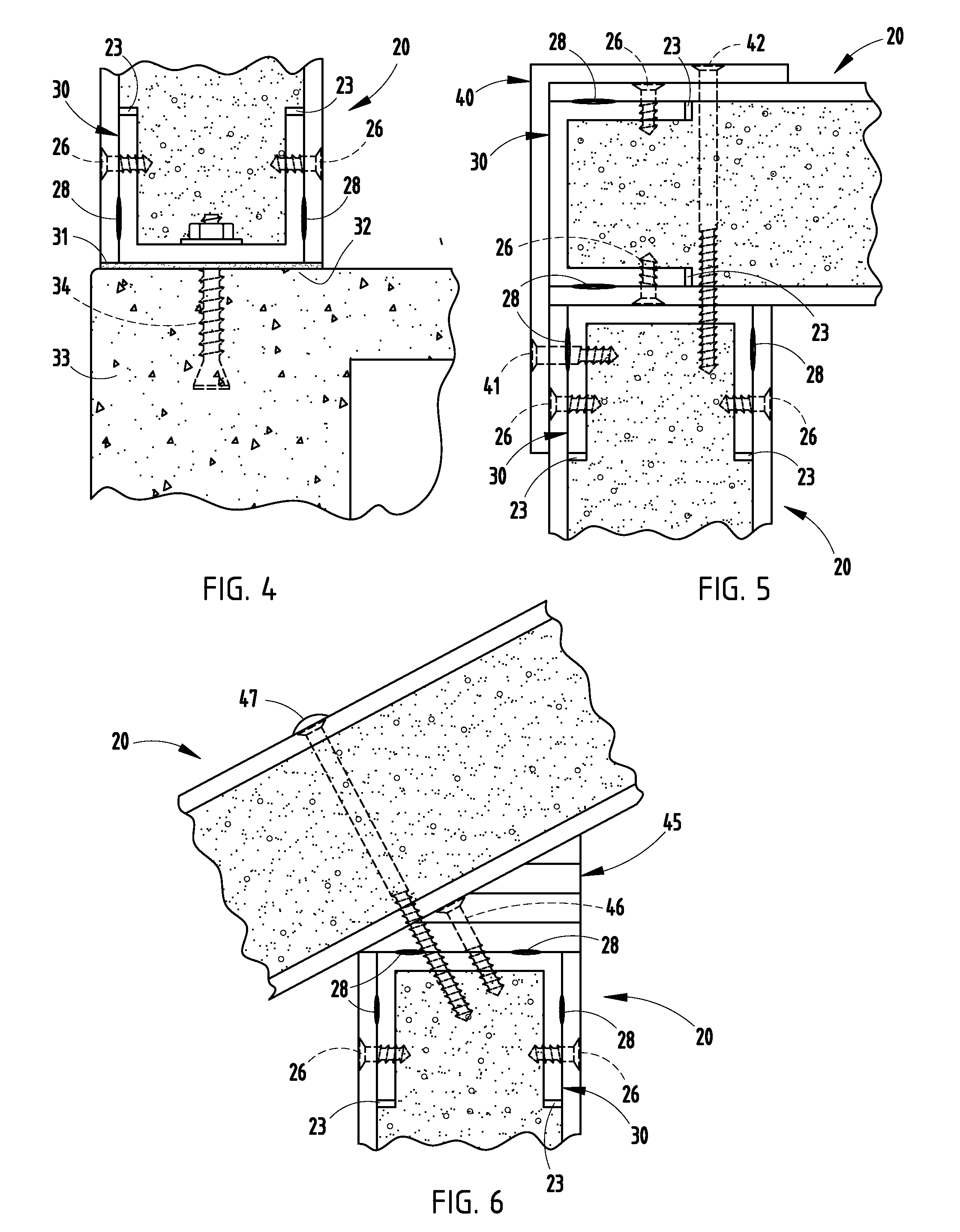

Embodiment Construction

[0012]The present concept includes the use of magnesium oxide (or other cementitious material) and fiberglass reinforcement for the juncture system that joins the SIP panels with inorganic faces. “Standard” shapes are used to make for a minimum of parts. Connecting shapes (also called “connecting junctures”) are made of magnesium oxide that is reinforced with the fiberglass for optimal strength, with a thickness of the shape being approximately the same thickness as the outside face used on the magnesium oxide SIP. It is contemplated that other cementitious materials may be substituted for the magnesium oxide shapes except the shapes may have thinner flanges, which can complicate construction. It is also contemplated that the reinforcement can be materials other than fiberglass, including metal, virgin plastic, plastic composite, recycled plastic, and / or recycled carpet.

[0013]Typical thickness for the magnesium oxide panel and connecting shape might be 8 mm (or 0.314 inches) and if ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com