Cam lock for cantilever mounting device

a technology of mounting device and cam lock, which is applied in the direction of washstands, scaffold accessories, lightening support devices, etc., can solve the problems of rotating the adjustment dial, the tension pin the third cam cannot be rotated about the axis so as to increase or decrease the tension of the third joint, increase and reduce the tension of the first joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

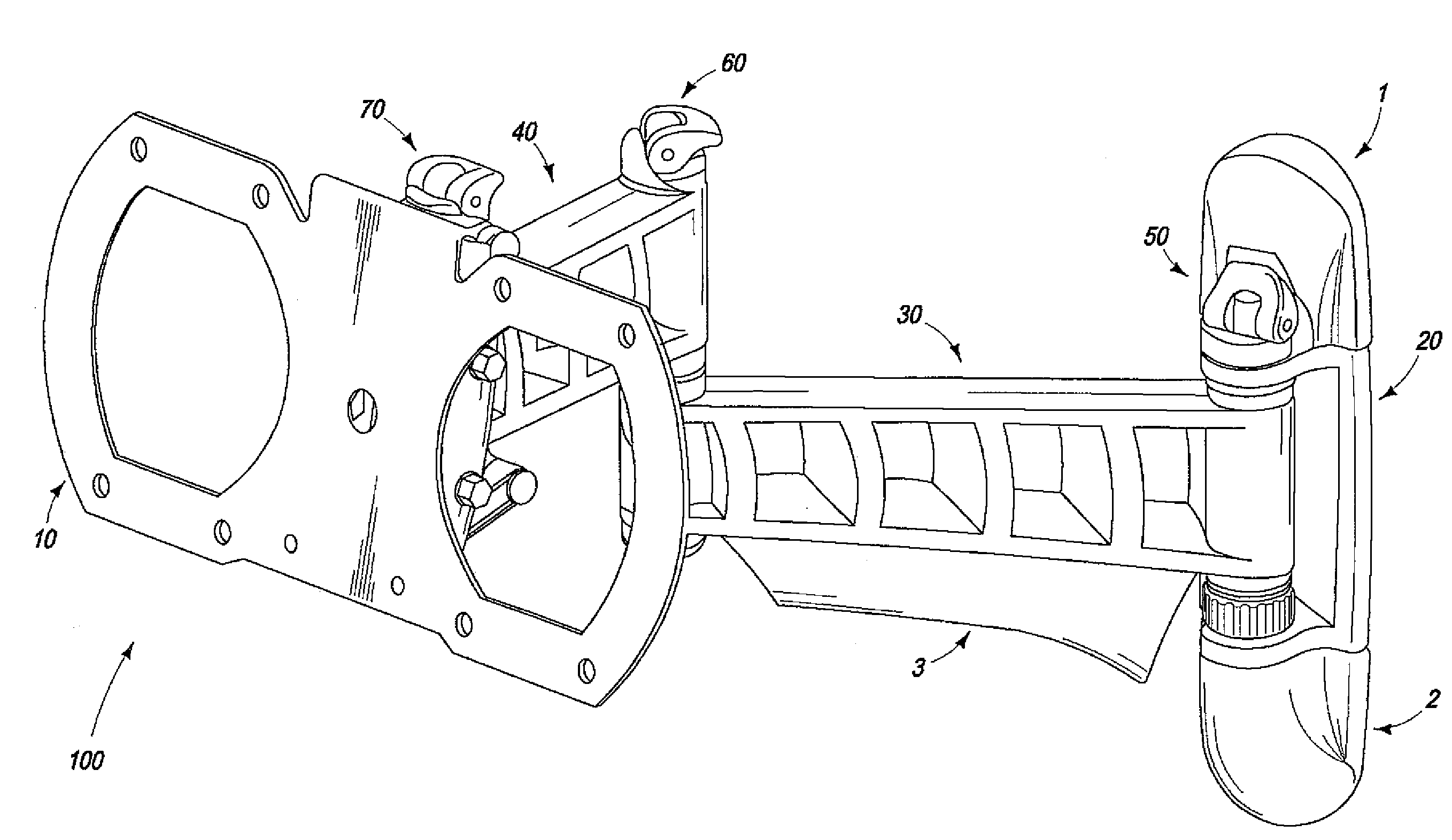

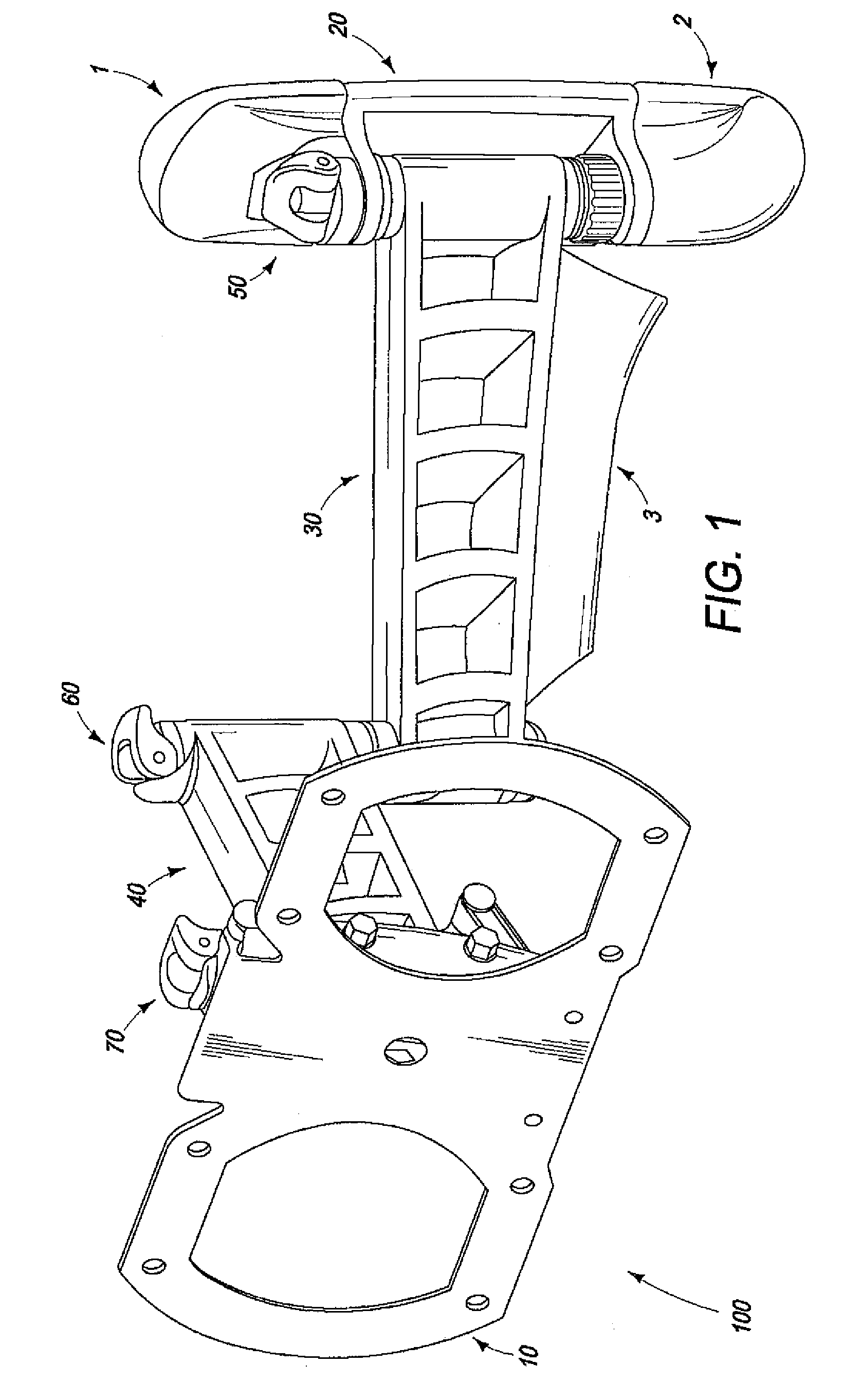

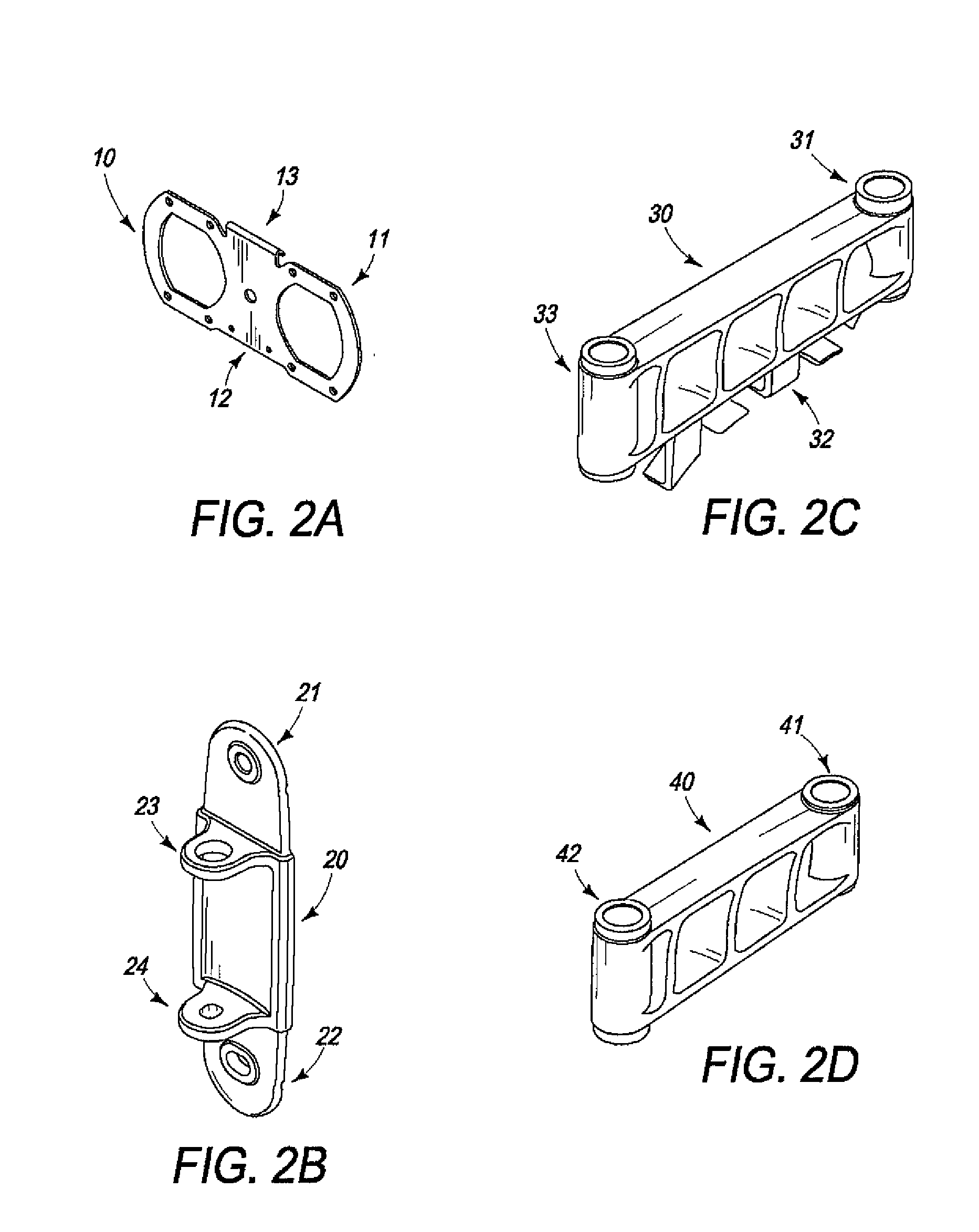

[0032]One embodiment of a mounting device 100 is illustrated in FIG. 1 and can be used to display a flat panel television against a wall in a home entertainment center. Mounting device 100 is a cantilever style device that includes a front member such as a front plate 10 for mounting a flat-panel display, electronic device, or any other object suitable for mounting. Opposite front plate 10 is provided a back member or back plate 20 for attaching mounting device 100 to a support structure able to bear the weight of mounting device 100 and mounted object. The support structure is preferably a wall but can be any load-bearing structure. Plastic caps 1 and 2 are provided to cover the top and bottom portions of back plate 20. Caps 1 and 2 conceal screws (not shown) provided to attach back plate 20 to a wall, and will be discussed in more detail with respect to FIG. 2B. A lower arm cap 3 is optionally provided below lower arm 30 to conceal back plate 20 from view.

[0033]Mounting device 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com