Spring Tube And A Spring Pack For Spring Mattresses

a technology of spring mattress and spring tube, which is applied in the direction of seating furniture, sofas, and mattresses, can solve the problems of mattresses obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

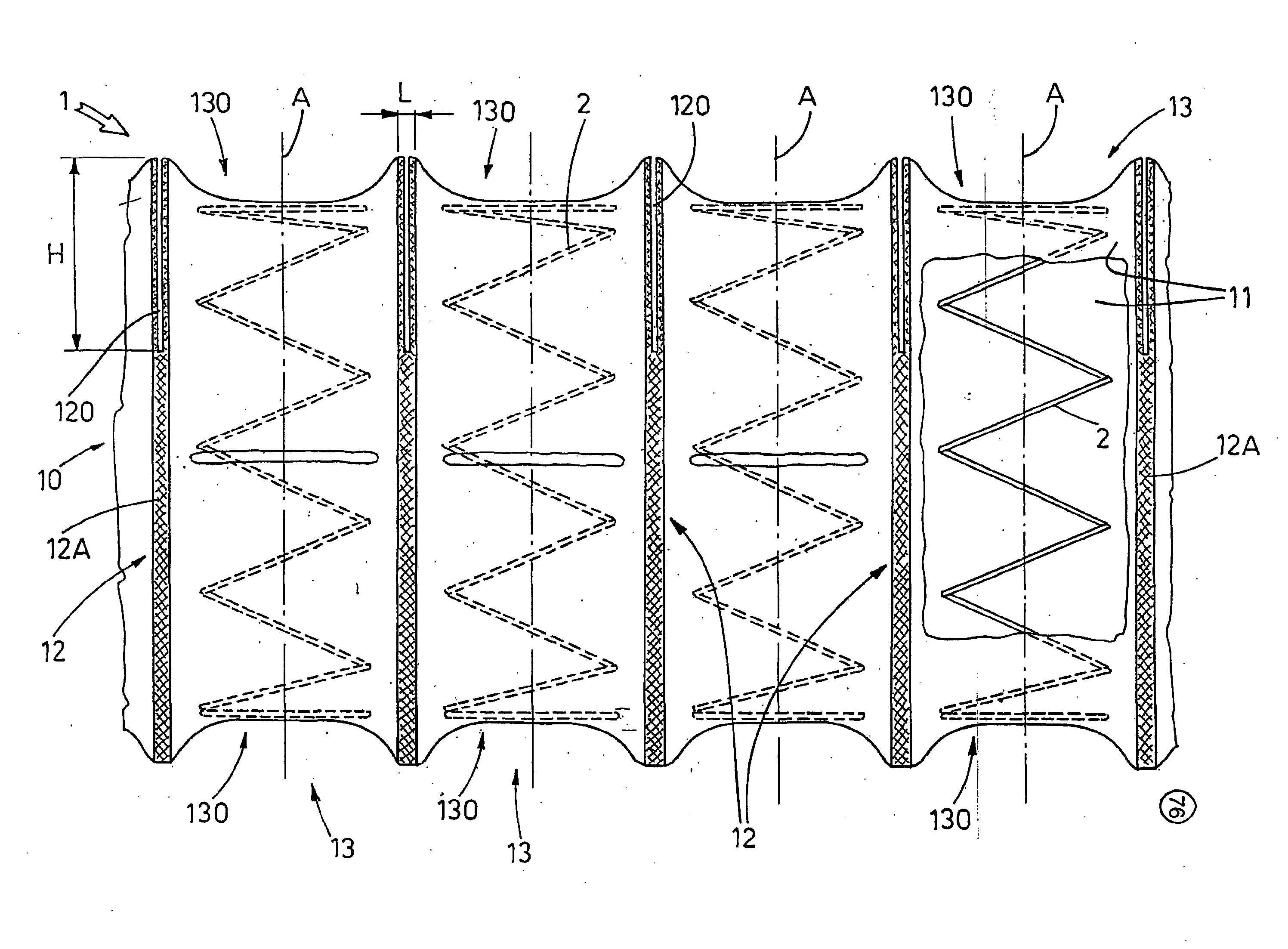

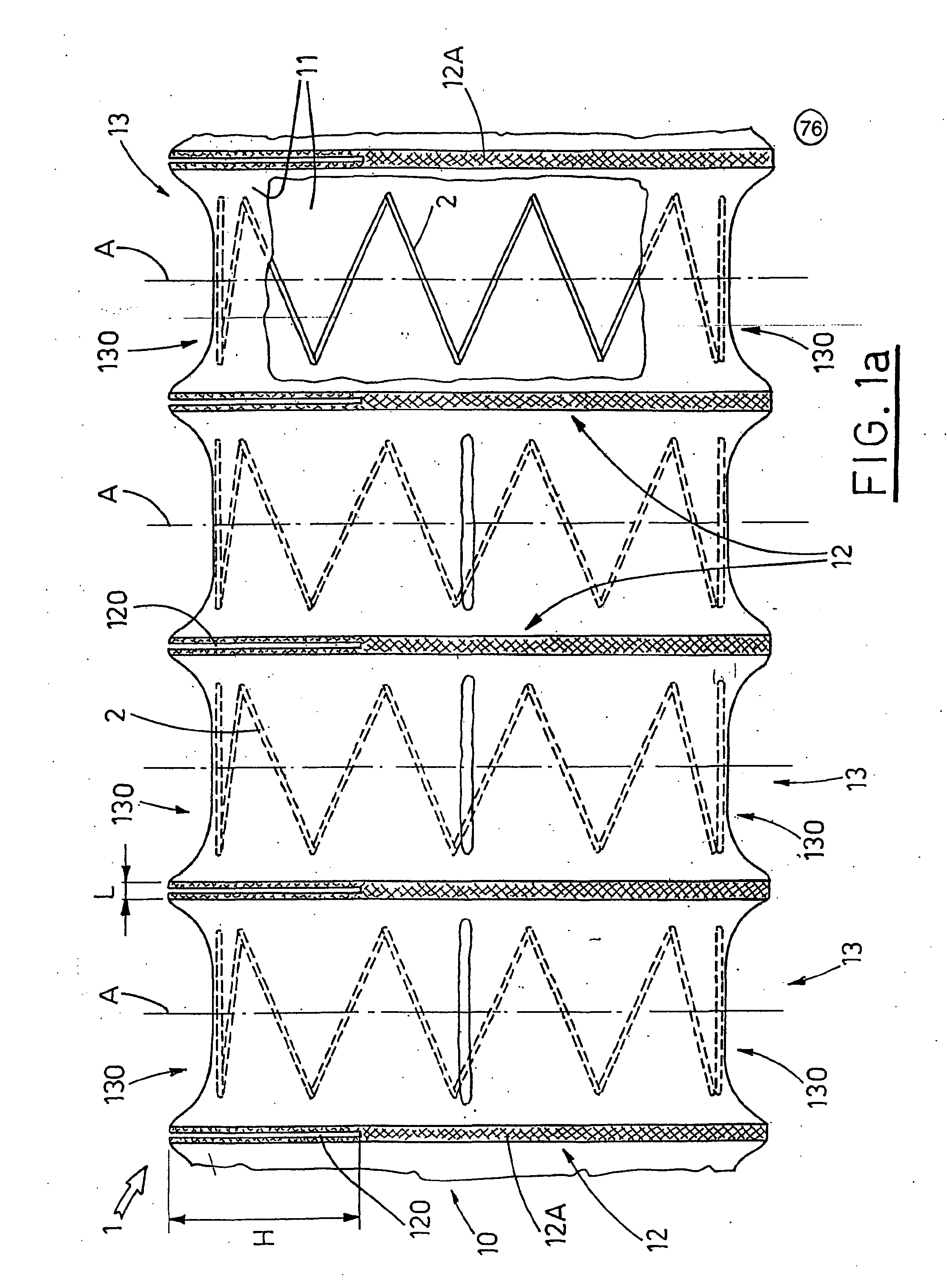

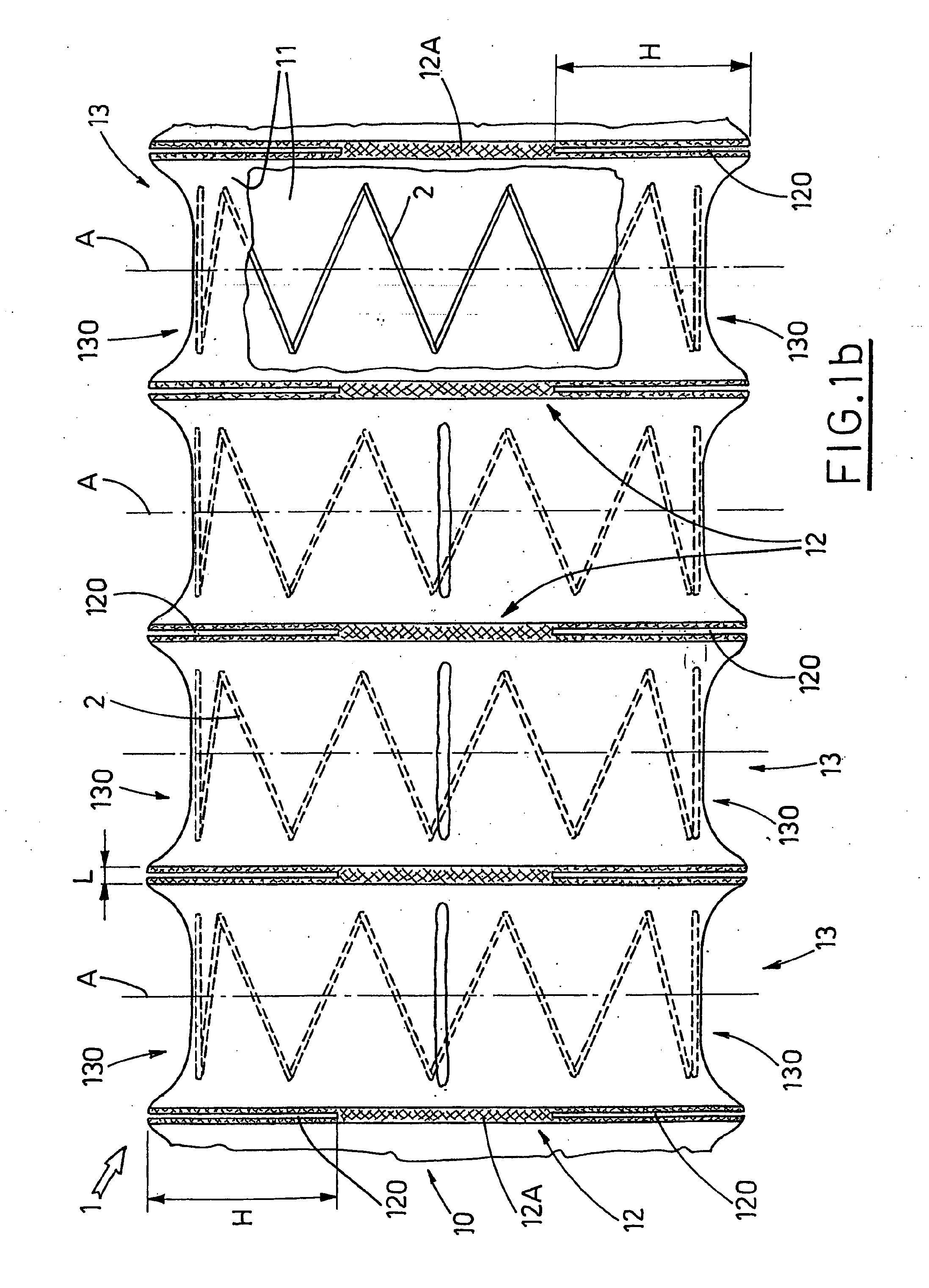

[0022]Referring to the above mentioned Figures, reference numeral 1 indicates the spring tube from which the spring pack for mattresses proposed by the invention is obtained.

[0023]The spring tube 1, like the known ones, includes a tube 10 of floppy plastic material, within which the springs 2 are enclosed and kept arranged side by side, at a selected distance.

[0024]The parts of the tube wall between one spring 2 and the subsequent one, are joined by welding lines 12, crossing the whole tube side to side, obtained e.g. by ultrasound welding. The welding lines are parallel to the axes A of the springs 2, so that each spring is contained within a closed portion 13 of the tube 10, separated from adjacent portions 13 (FIGS. 1a and 1b).

[0025]According to the invention, the welding lines 12 have a width L sufficient to assure the sealing of the portions 13 even after having done longitudinal cuts 120 along a center line of each portion 13.

[0026]According to a first preferred embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com