Lower hand guard with heat shield for use with a modular integrated rail system

a rail system and lower hand guard technology, applied in the direction of weapons, butts, weapon components, etc., can solve the problems of damage or destruction of attachments that are mounted in direct contact, insufficient space on the integrated rail provided on the upper receiver to accommodate all of the desired accessories, and limited space on the upper receiver rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

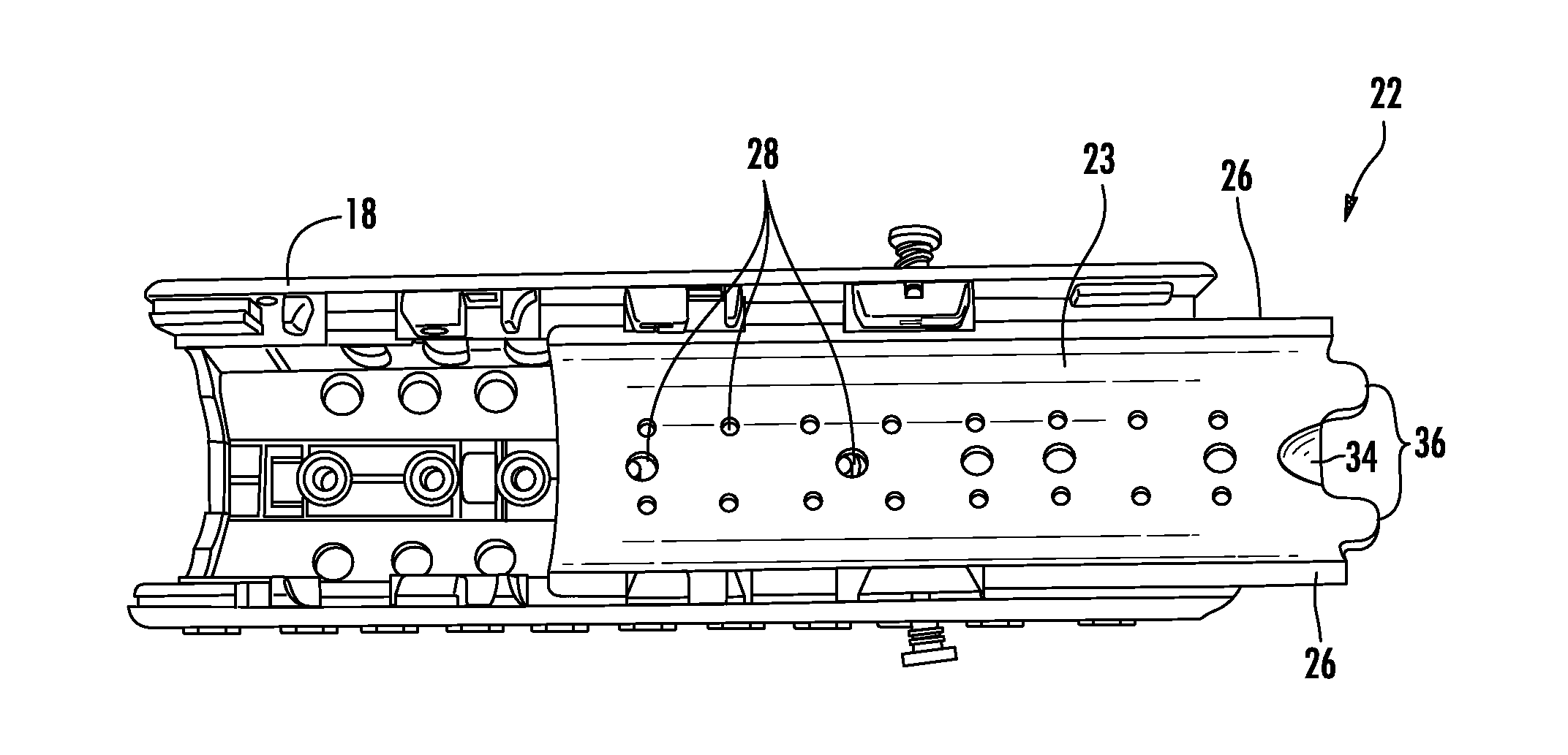

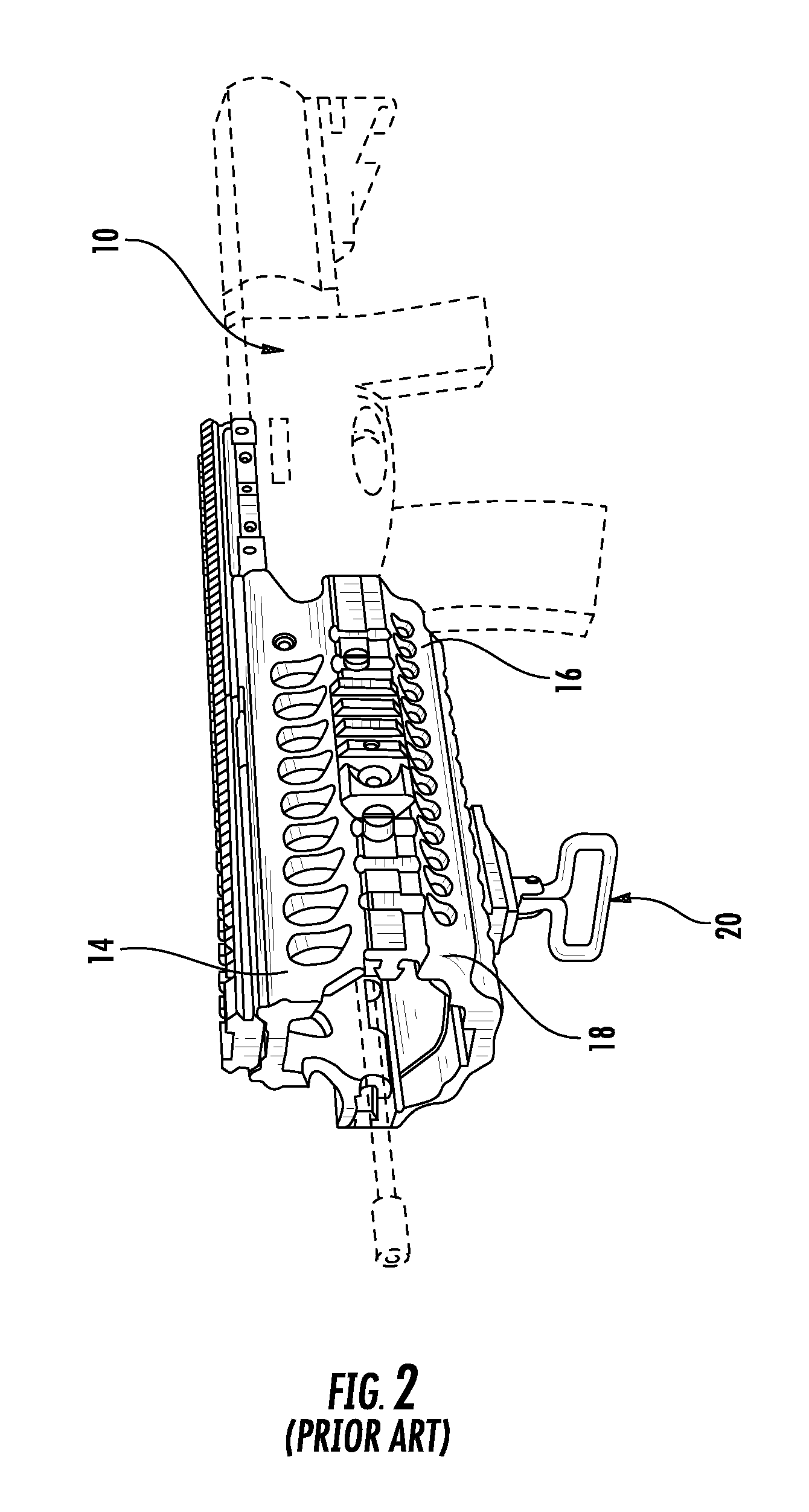

[0028]Now referring to the drawings, the heat shield of the present invention system is shown and generally illustrated at FIGS. 4-9. As can be seen, the present invention is directed to a metal heat shield insert 22 that is received into the lower hand guard 18. The heat shield 22 is received and supported in a pair of opposing mounting channels 24 that are formed on the inside of the lower hand guard 18. Generally, the heat shield 22 comprises an elongated metal sheet having a curved central body portion 23, and mounting flanges 26 extending along opposing side edges. The mounting flanges 26 are slidably received into the opposing channels 24 formed in the lower hand guard 18 to support the heat shield 22 within the interior of the lower hand guard 18. The body 23 of the heat shield 22 includes a plurality of venting holes 28 to permit air to flow through the heat shield 22. It should be noted that when the heat shield 22 is installed in assembled relation with the lower hand guar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com