Interlocking Hollow Tanks

a hollow tank and interlocking technology, applied in the field of hollow tanks, can solve problems such as the inability to overcome the inability to use conventional tanks, and achieve the effect of reducing the amount of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

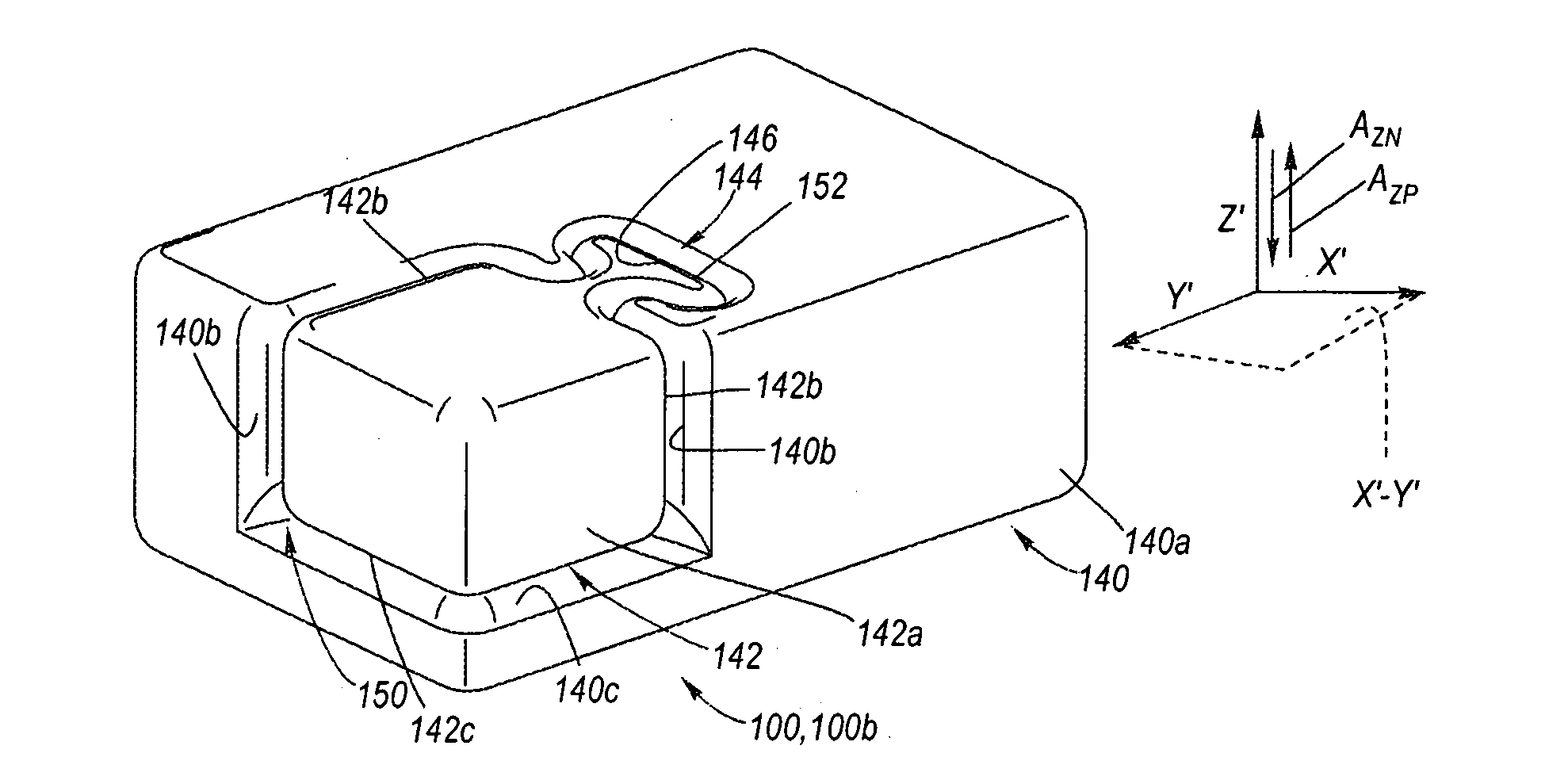

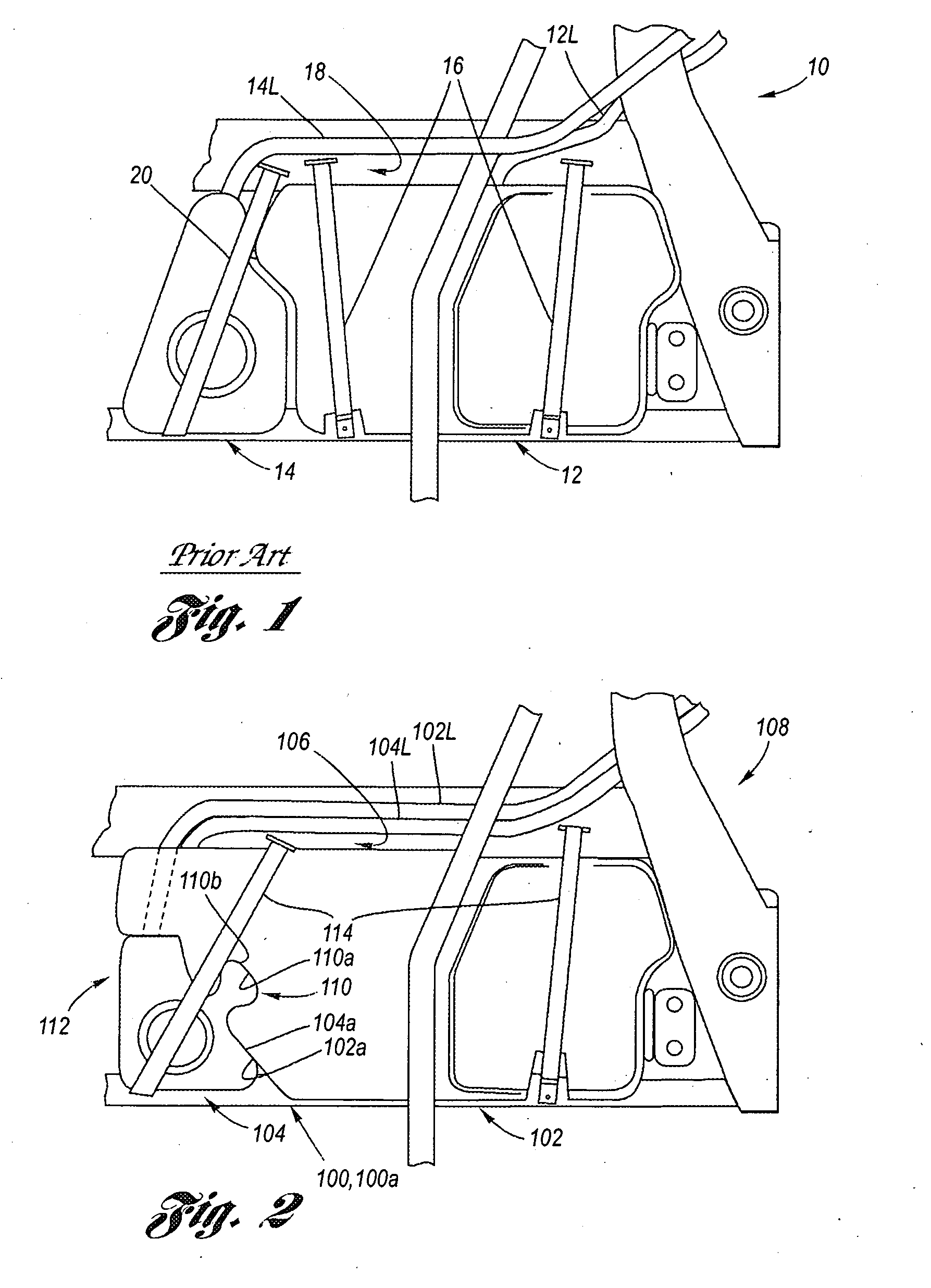

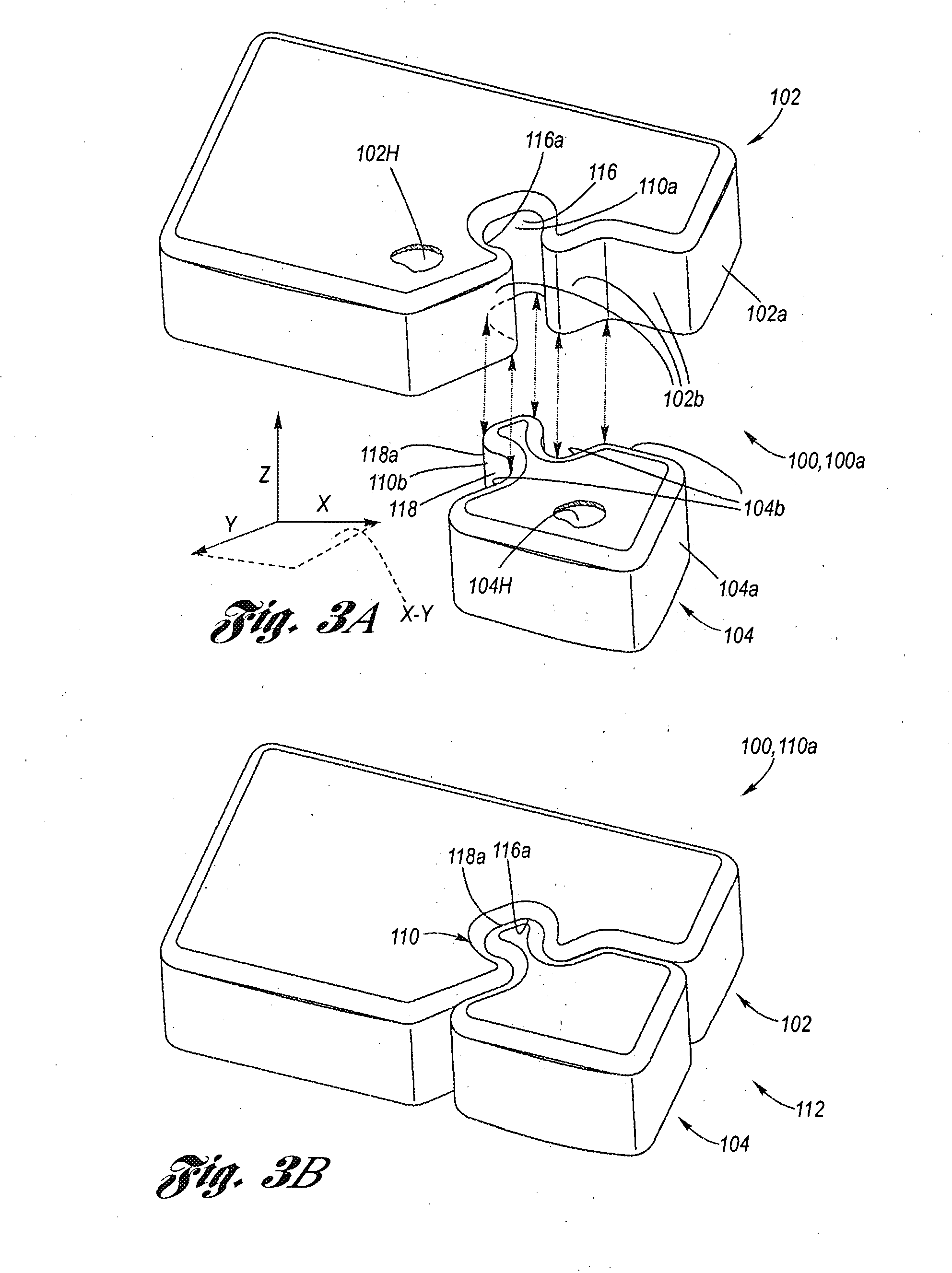

[0018]Referring now to the Drawing, FIGS. 2 through 4C depict examples of a set of interlocking tanks 100 according to the present invention.

[0019]An example of a motor vehicle application for a set of interlocking tanks 100, 100a according to the present invention is depicted at FIG. 2, wherein a diesel fuel tank 102 for holding within the hollow 102H thereof diesel fuel is interlocked with respect to its companion urea tank 104 for holding within the hollow 104H thereof urea. The diesel and urea tanks 102, 104 are shown disposed at the underbody 106 of a motor vehicle (shown in part) 108. The diesel fuel tank 102 has a sidewall 102a defining the hollow 102H of the diesel fuel tank and the urea tank 104 has a sidewall 104a defining the hollow 104H of the urea thank, wherein the sidewalls have cooperating interlock features 110 formed inclusive with the hollow of the tanks which are mutually correlated and reciprocally shaped so that a first interlock feature 110a of the diesel fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com