Heat dissipation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

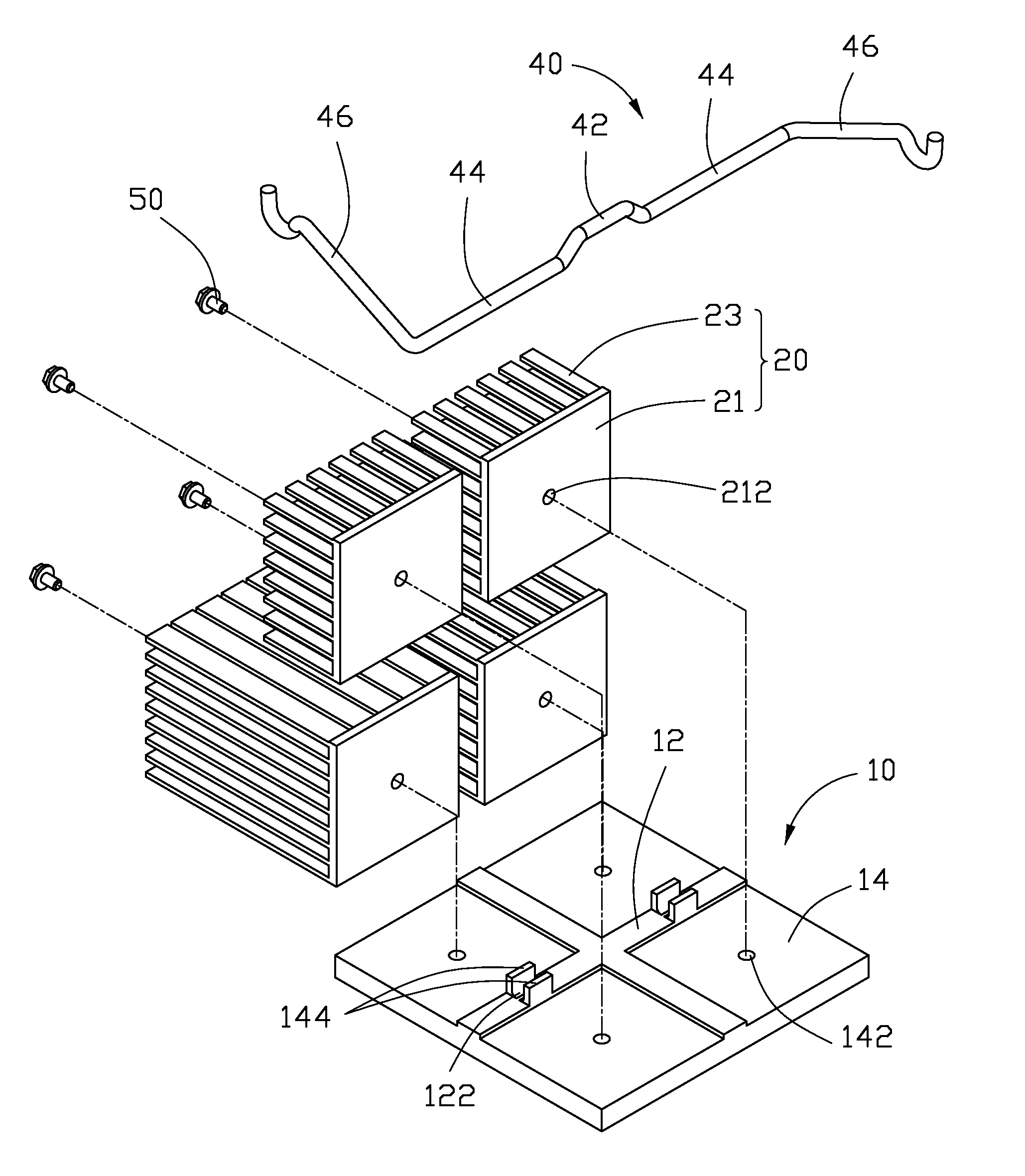

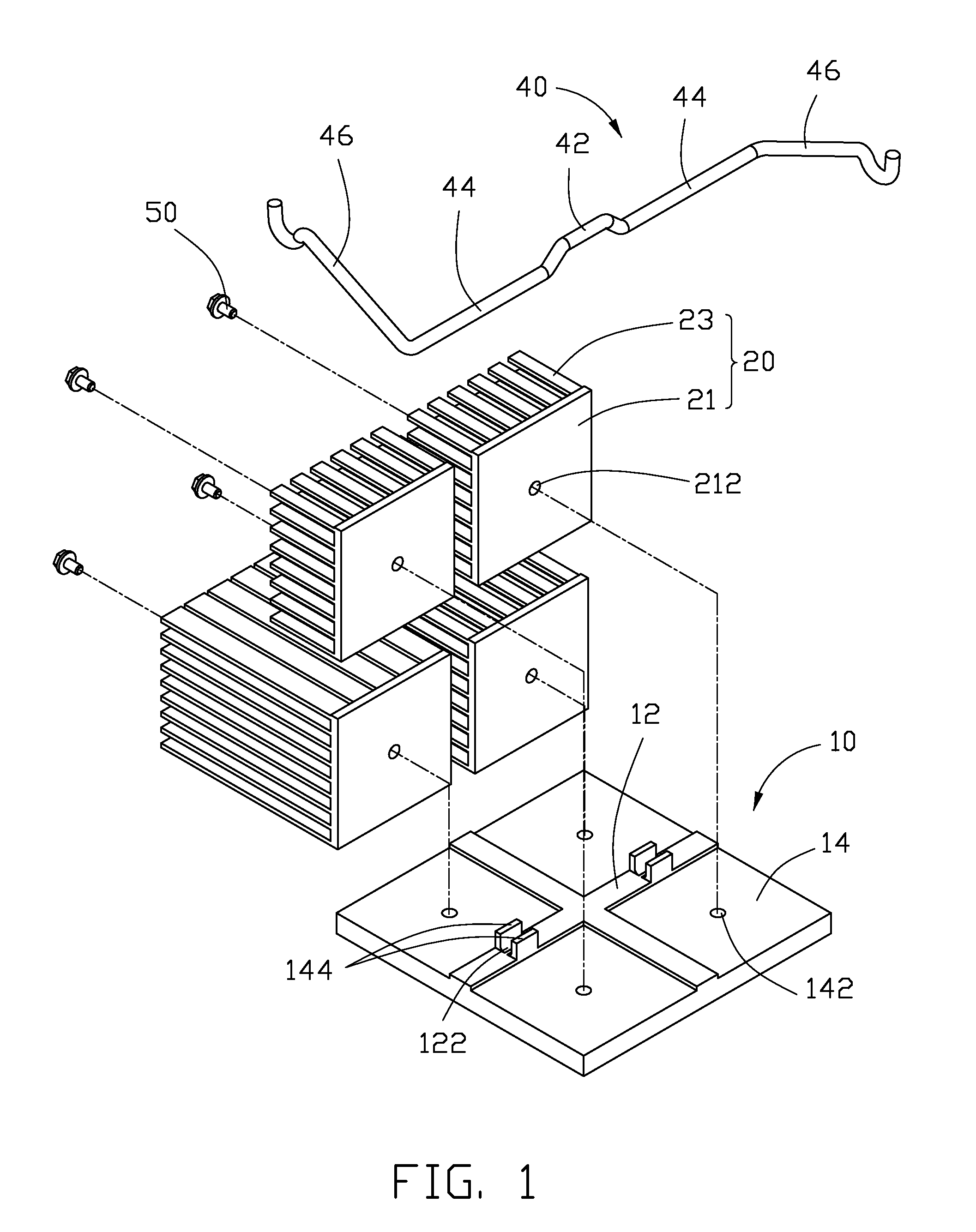

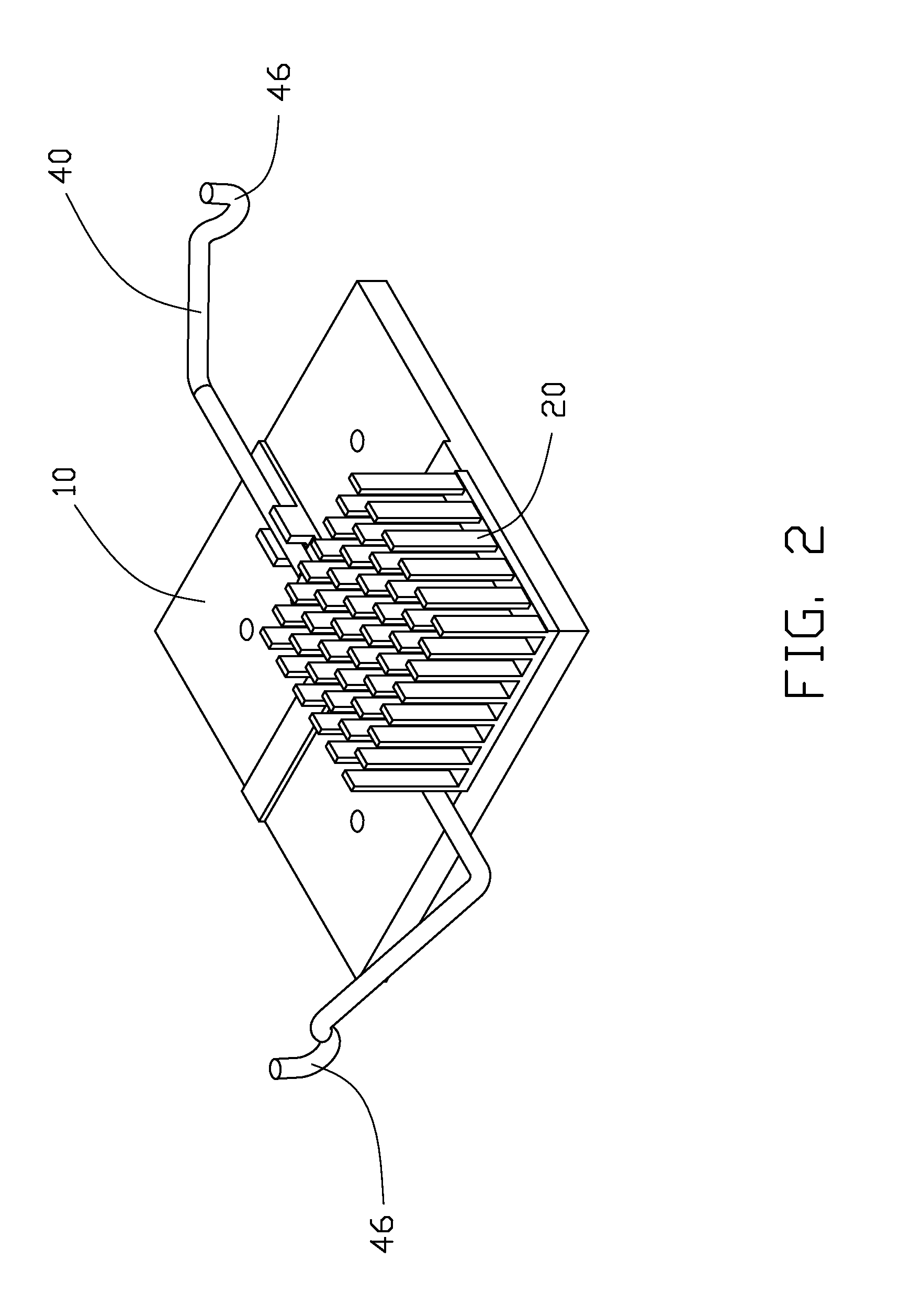

[0009]Referring to FIG. 1, an exemplary embodiment of a heat dissipation device includes a square plate 10 to be located on a top of an electronic element, such as a bridge chip of a circuit board. Four heat sinks 20 mounted on the plate 10 to absorb heat from the electronic element. A clip 40 made of resilient material to fix the plate 10 on the circuit board, and four fasteners 50, such as four screws, to mount the heat sinks 20 to the plate 10.

[0010]Each heat sink 20 includes a base 21 and a plurality of parallel fins 23 extending perpendicular from the base 21. A fixing hole 212 is defined in a center of the base 21. In one embodiment, the bases 21 of the heat sinks 20 are the same, while heights of the plurality of fins 23 of each heat sink 20 differ. Size of the base 21 and height of the plurality of fins 23 of each heat sink 20 can be predetermined according to need. The number of the heat sinks 20 can be selected according to heat dissipation requirement of the electronic el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com