Controls for ventilation and exhaust ducts and fans

a technology of control and ventilation duct, which is applied in the direction of ventilation systems, heating types, and domestic stoves or ranges, etc., can solve the problems of increased power consumption, ineffective or inefficient fume and/or smoke extraction, and excessive use of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

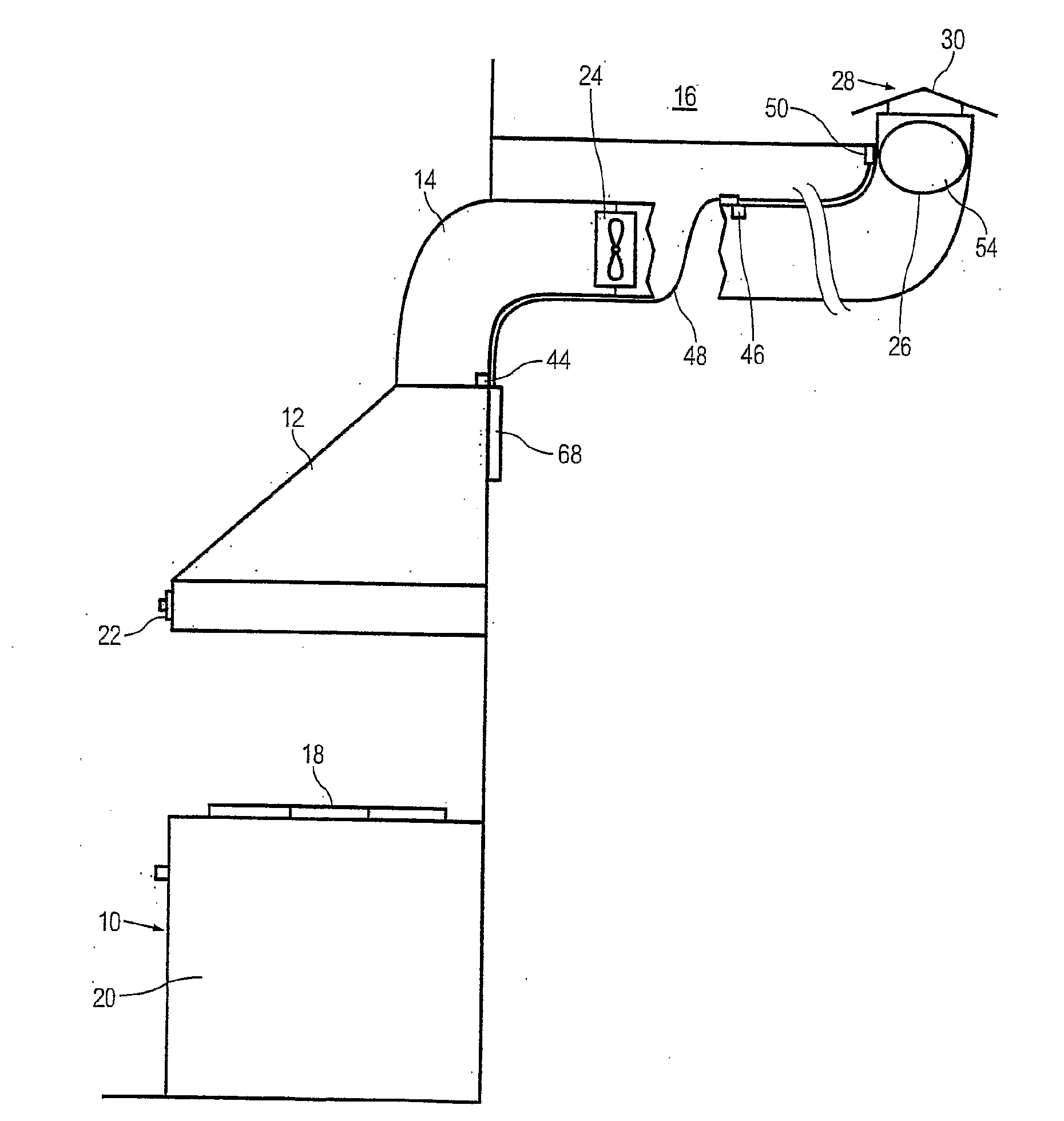

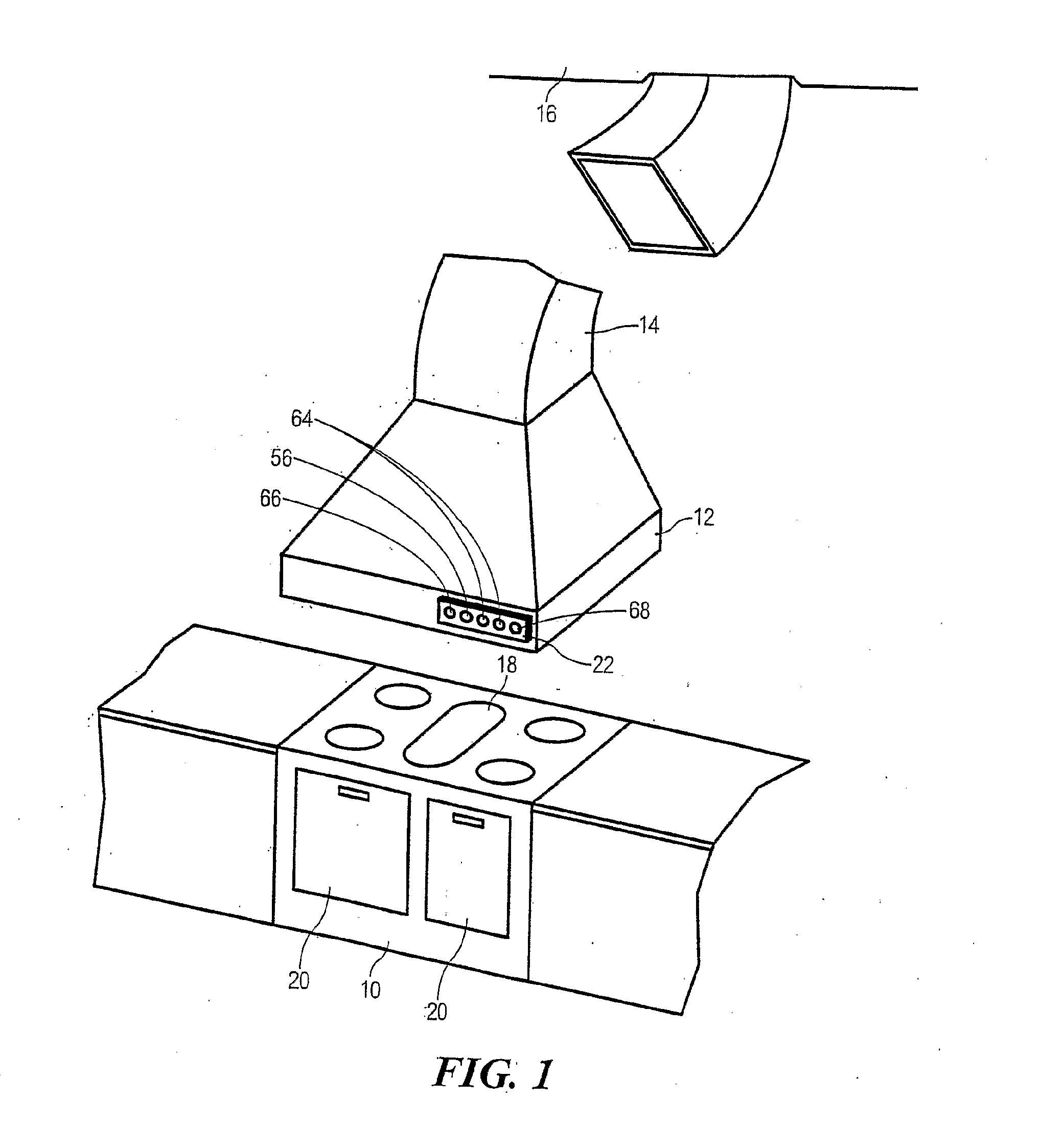

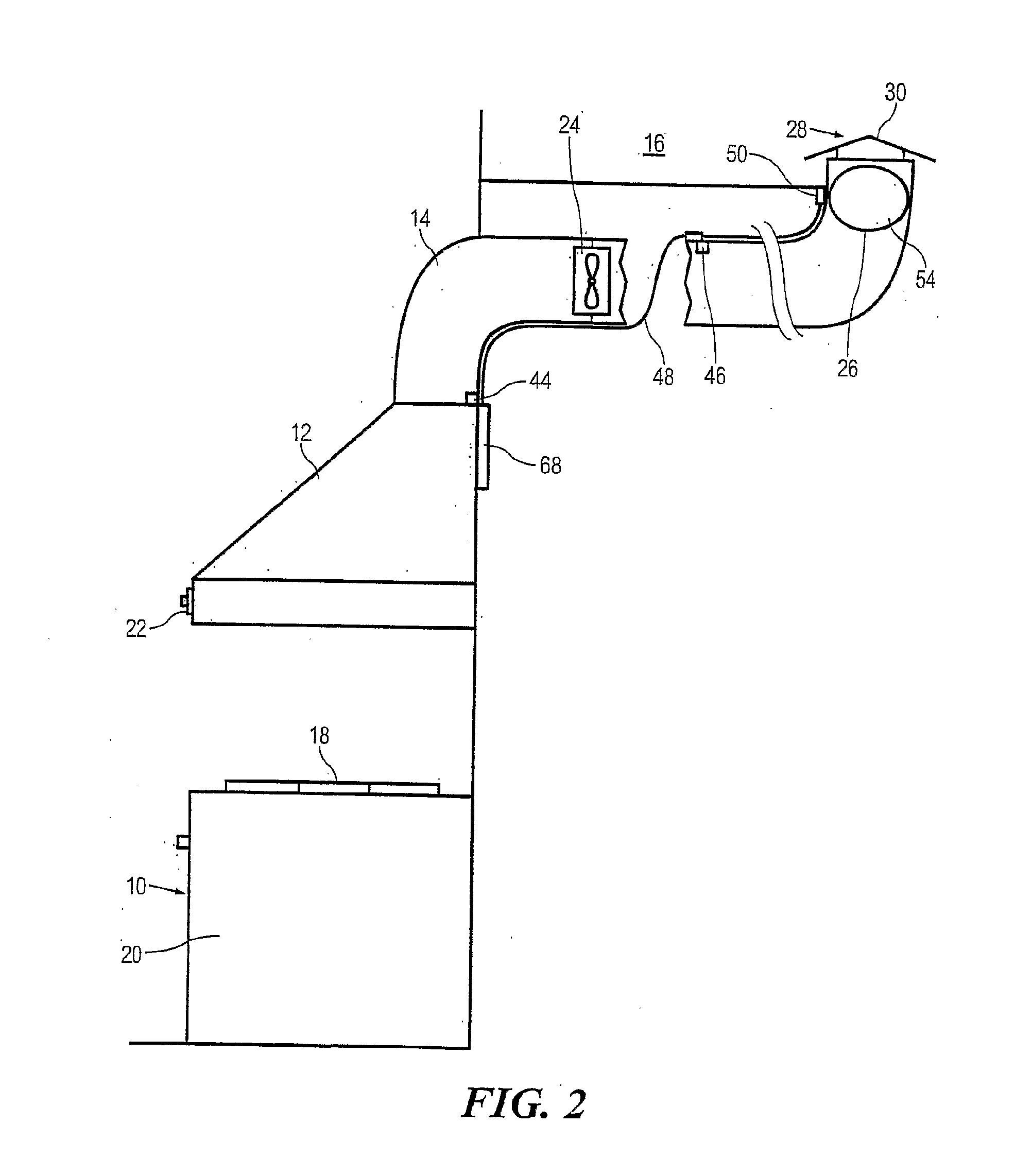

[0046]To refer to FIGS. 1 and 2, there is illustrated a commercial stove 10 with an exhaust hood 12. Ducting 14 connects the exhaust hood 12 to the outside atmosphere 16. Although a stove 10 is shown, it could be any commercial or industrial equipment that produces or uses smoke and / or fumes and / or noxious gasses, a car park for removing vehicle exhaust fumes, and so forth.

[0047]The stove 10 has hobs 18 for use in the cooking of food, and are or more ovens 20 also used in the cooking of food.

[0048]The exhaust hood 12 has a control panel 22 for controlling the operation of the exhaust hood 12, including the operation of a fan assembly 24. Although a single fan assembly 24 is shown, there may be two or more fan assemblies. The fan assembly 24 may be of any suitable form or nature. Preferably, the fan assembly 24 is multiple speed.

[0049]Also in ducting 14 is a valve 26 that is shown in the open position in FIG. 2, and which is adjacent the outlet end 28 of the ducting 14. The outlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com