Transformable structure for producing a multi thread single line stitch and method and machine for its realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

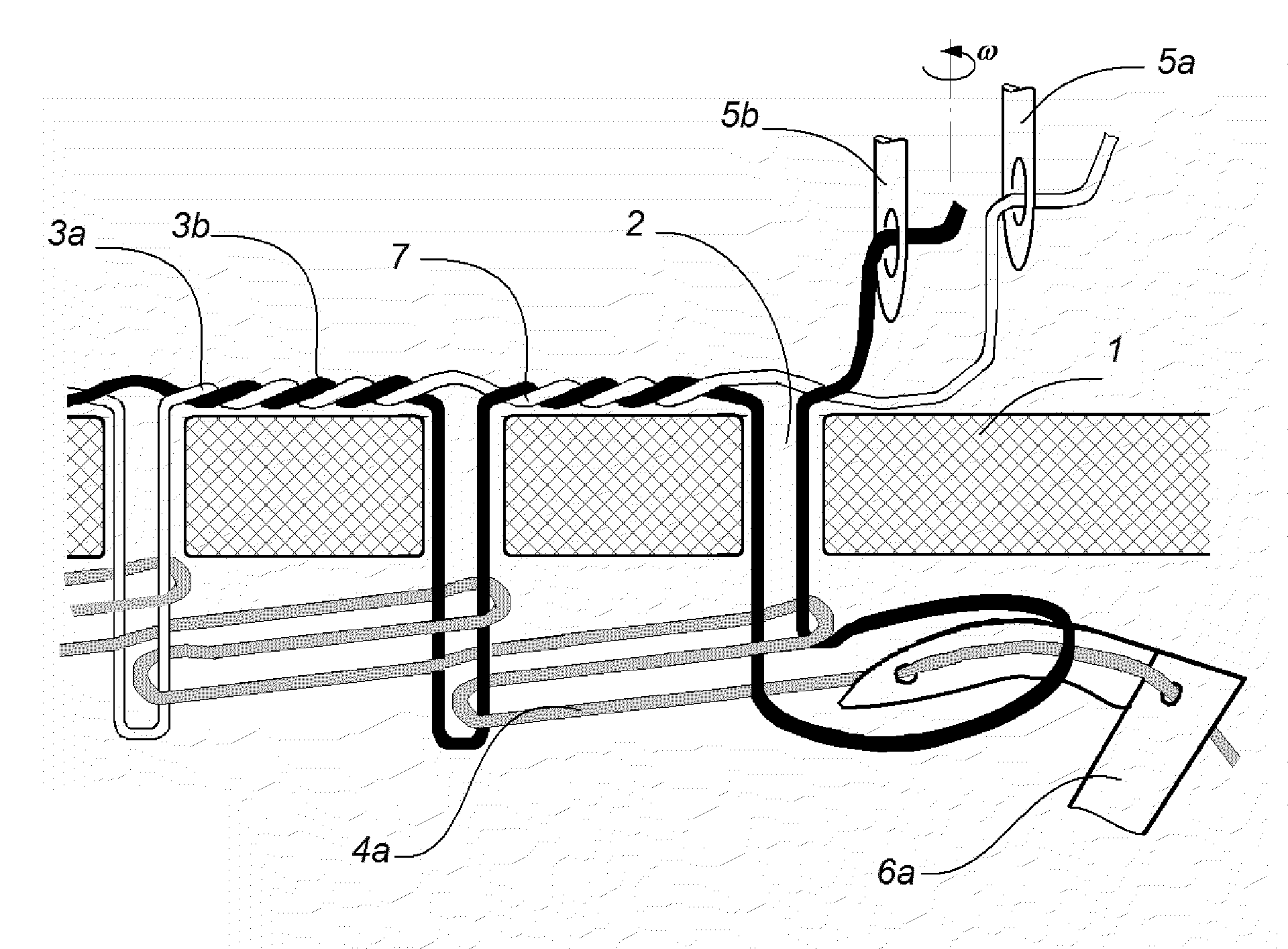

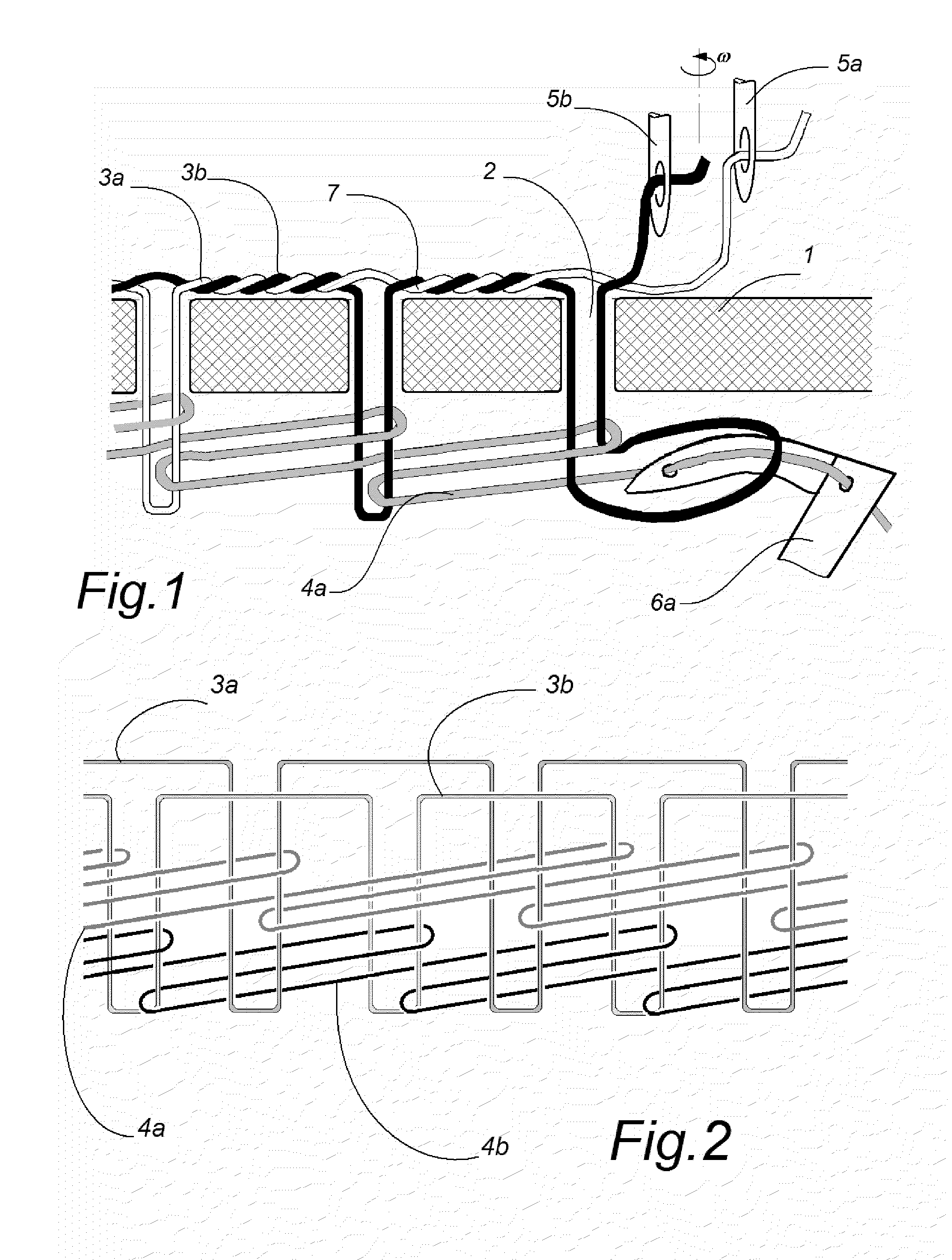

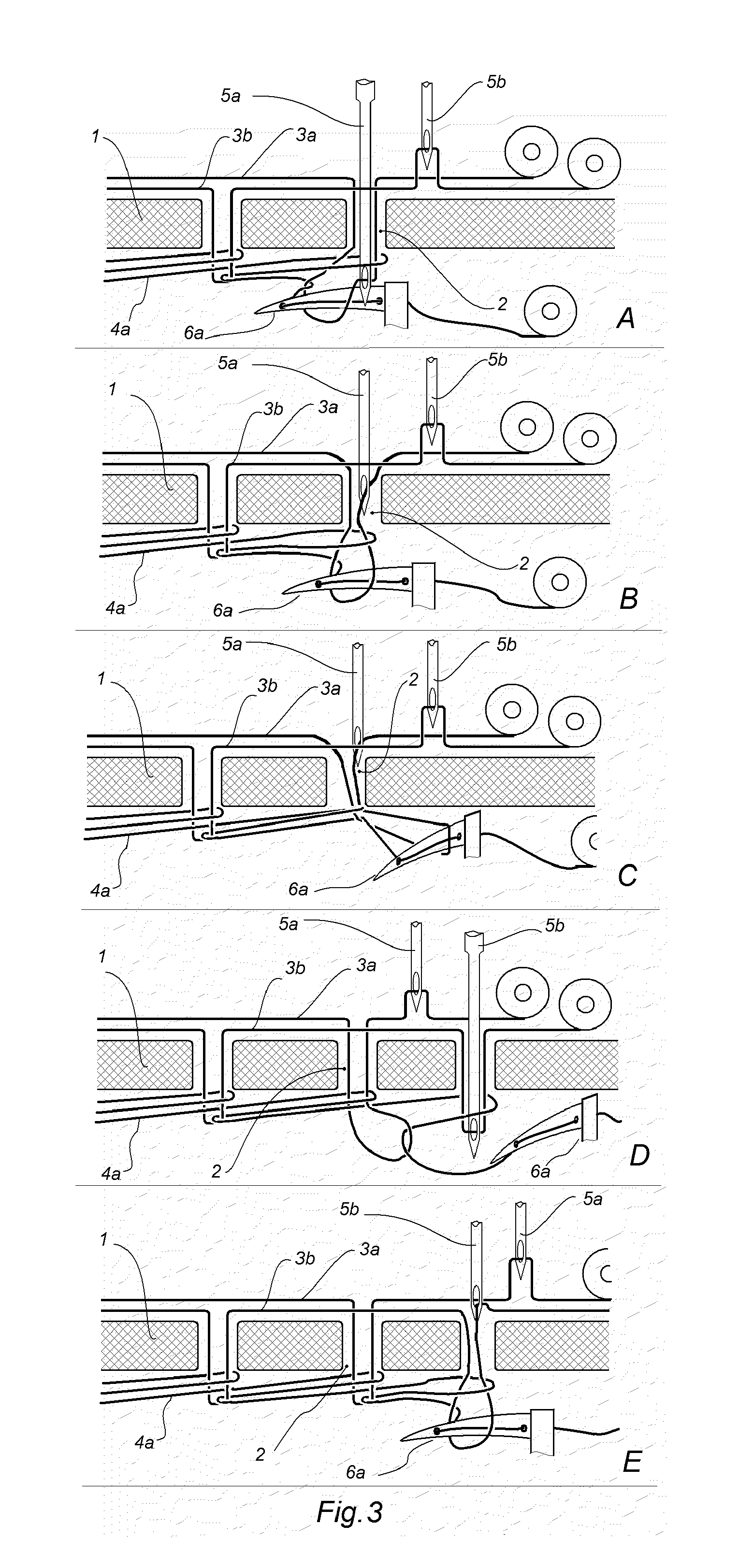

[0066]FIGS. 1-11 disclose: 1—sewn material; 2—perforation; (p#1, p#2, p#3, p#4, p#5—numbers of perforations); 3a—first top thread; 3b—second top thread; 3c—third top thread; 4a—first bottom thread; 4b—second bottom thread; 5a—first top thread needle; 5b—second top thread needle; 5c—third top thread needle; 6a—first bottom thread looper; 6b—second bottom thread looper; 7—thread intertwining; 8—needle unit (needle revolver); 9—looper unit (looper revolver); 10—mechanism for discrete rotation of the needle revolver (e.g. Geneva wheel); 11—mechanism for discrete rotation of the looper revolver (e.g. Geneva wheel); 12—needle bar (12a—first needle bar; 12b—second needle bar); 13—needle bar engaging mechanism; 14—needle bar catching device; 15—needle bar shoulder (15a—first needle bar shoulder; 15b—second needle bar shoulder); 16a—module of needle and thread feeder mechanism of the first needle; 16b—module of needle and thread feeder mechanism of the second needle; 17—bobbin holder with bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com