Vented package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

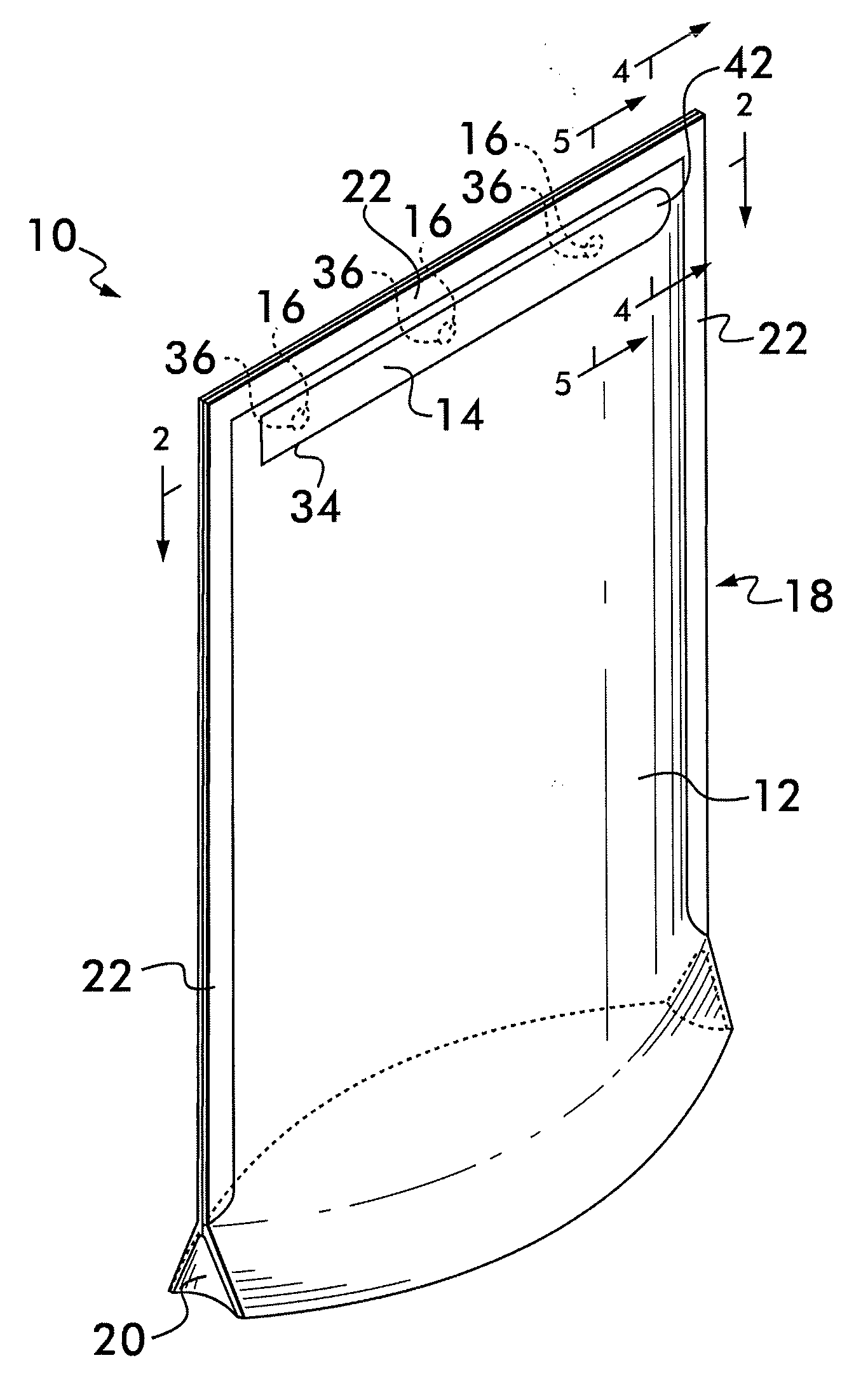

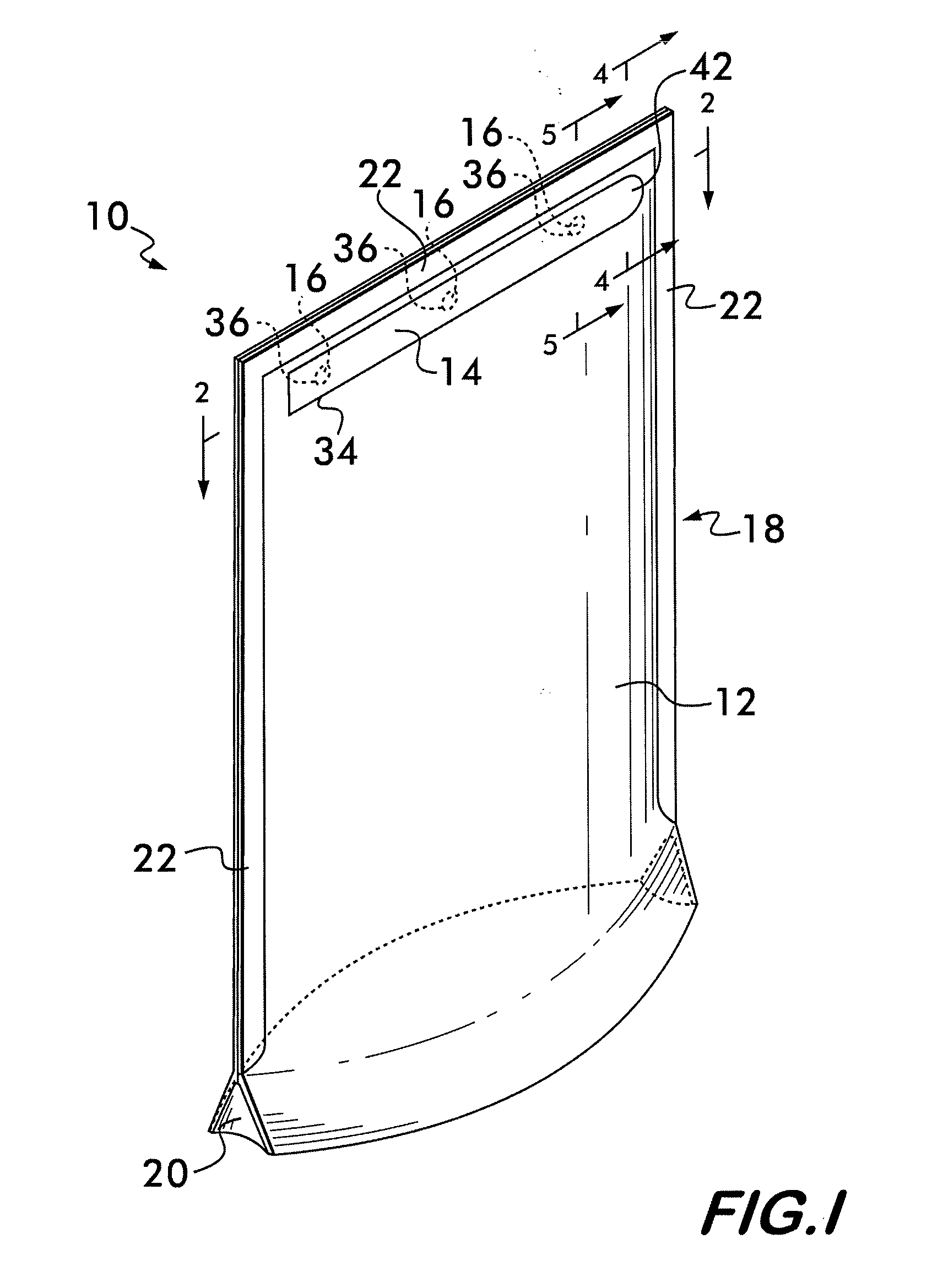

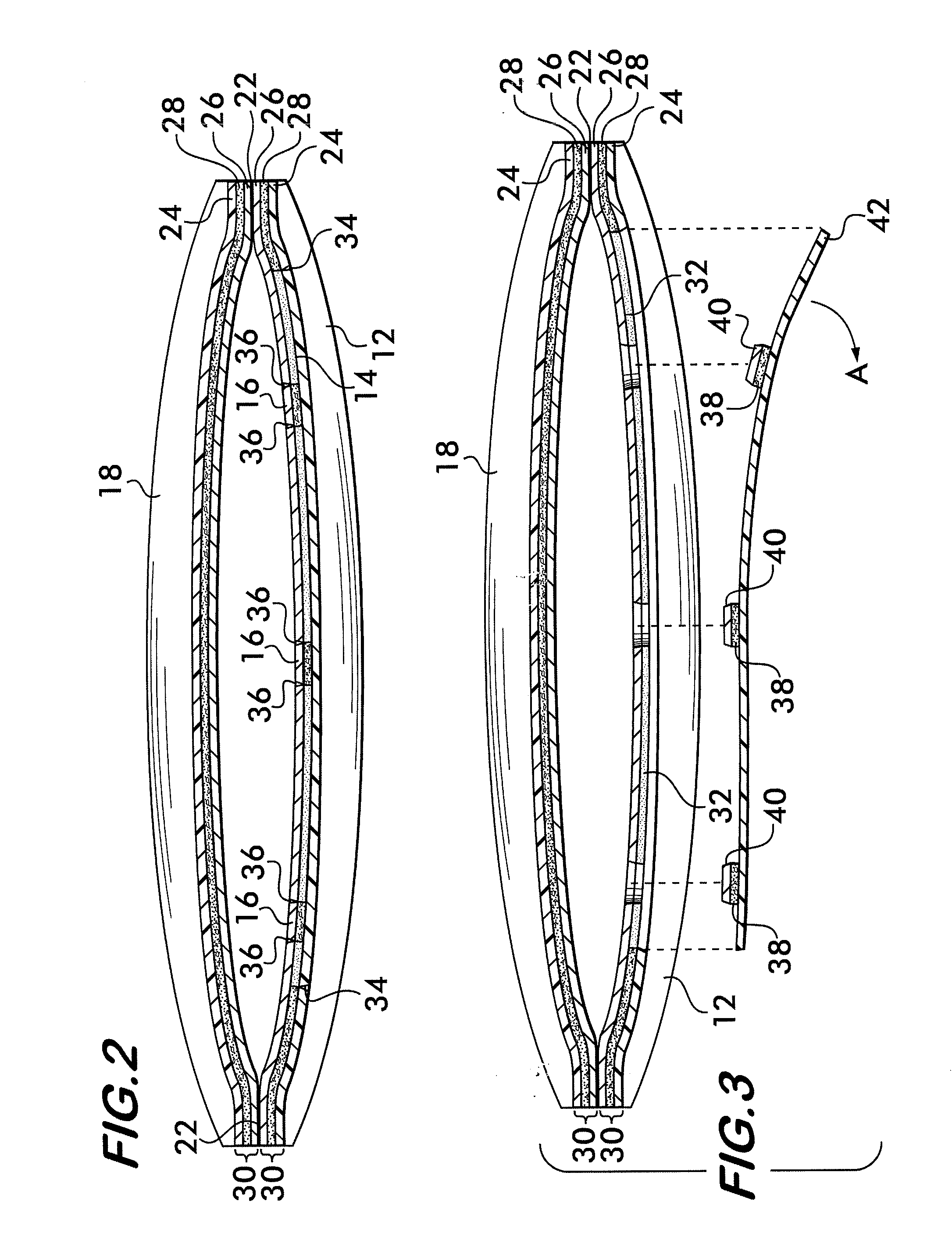

Referring to the figures, like numerals are used to indicate like elements throughout. FIGS. 1-6 show an embodiment of a flexible package generally identified by reference numeral 10. The package 10 is shown as having a generally rectangular construction, but may have any desired shape. As illustrated, the package 10 includes a first panel 12 having a removable tab 14, which covers formed vents 16.

Referring to FIG. 1, the package 10 is shown in the form of a stand up pouch having a first panel 12, an opposing second panel 18 and a bottom gusset panel 20. The first panel 12 is secured to the second panel 18 by a heat seal 22 extending along their top edges and along the upper side portions of the package 10. The gusset panel 20 is also preferably heat-sealed to the first panel 12 and second panel 18 adjacent their lower portions and along their bottom edges, providing a base for the package 10.

As shown in FIGS. 2 and 3, the first and second panels 12, 18 are constructed of a multi-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com