Refrigeration compressor with internal cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

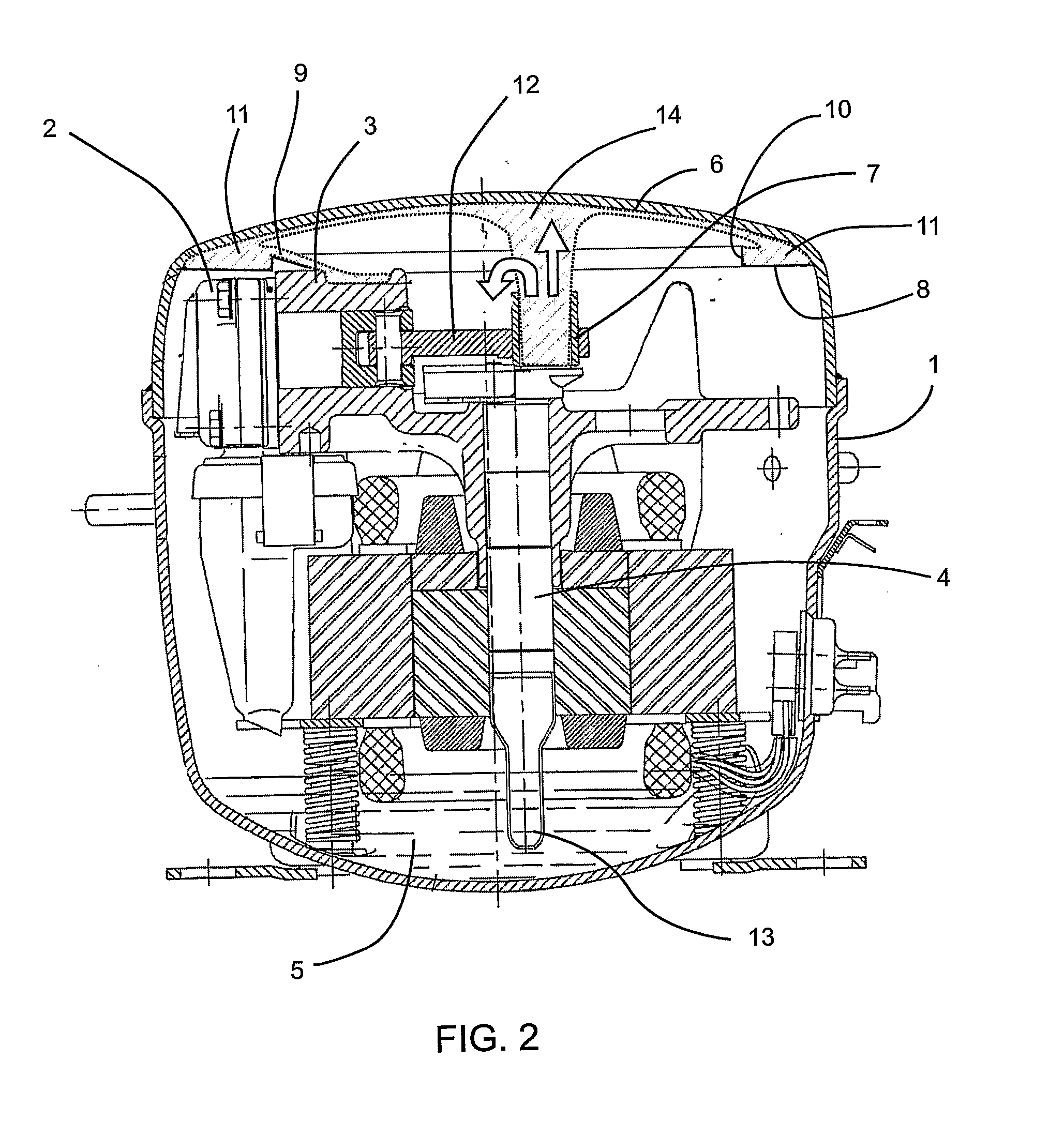

DETAILED DESCRIPTION OF THE DRAWINGS

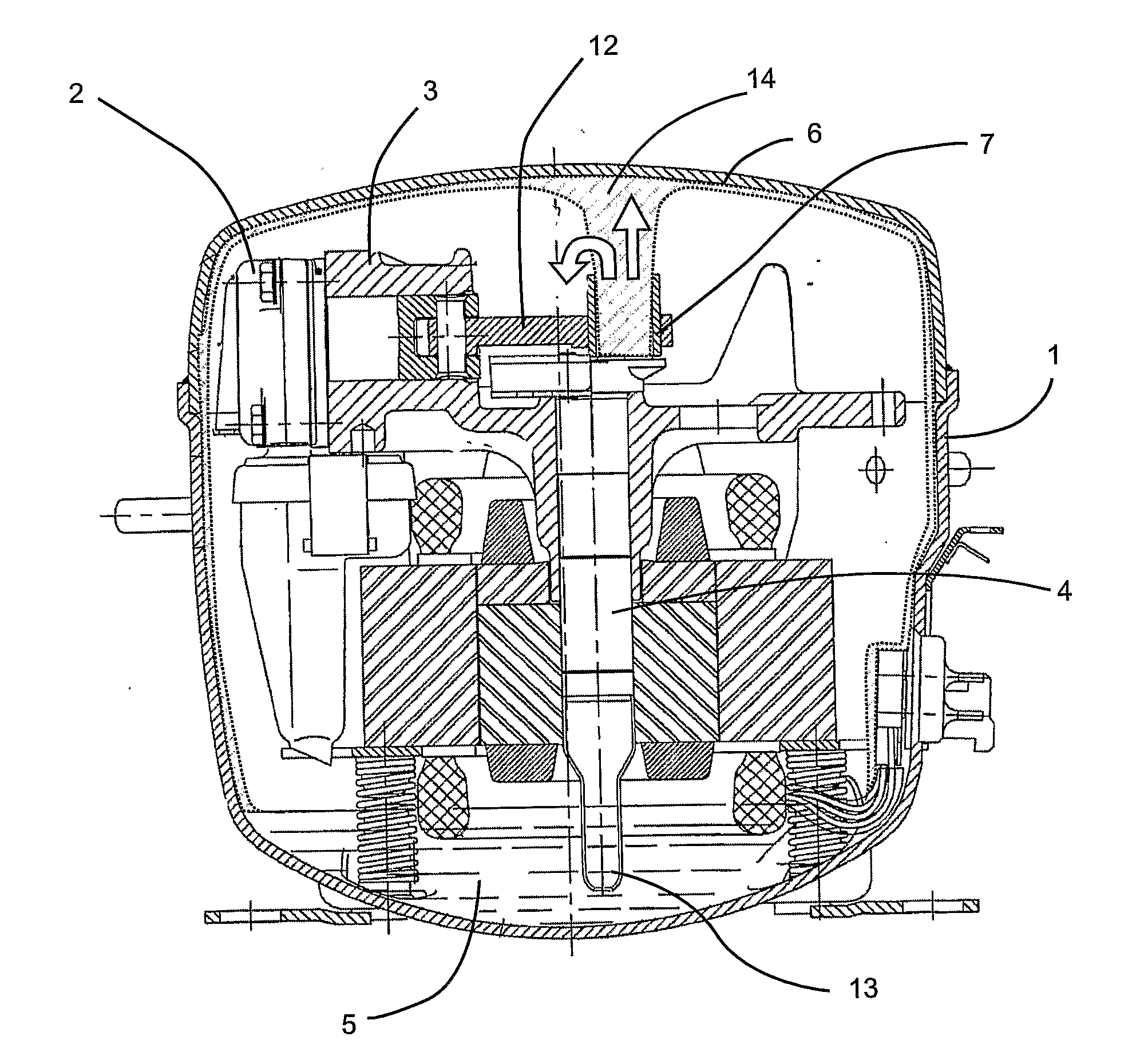

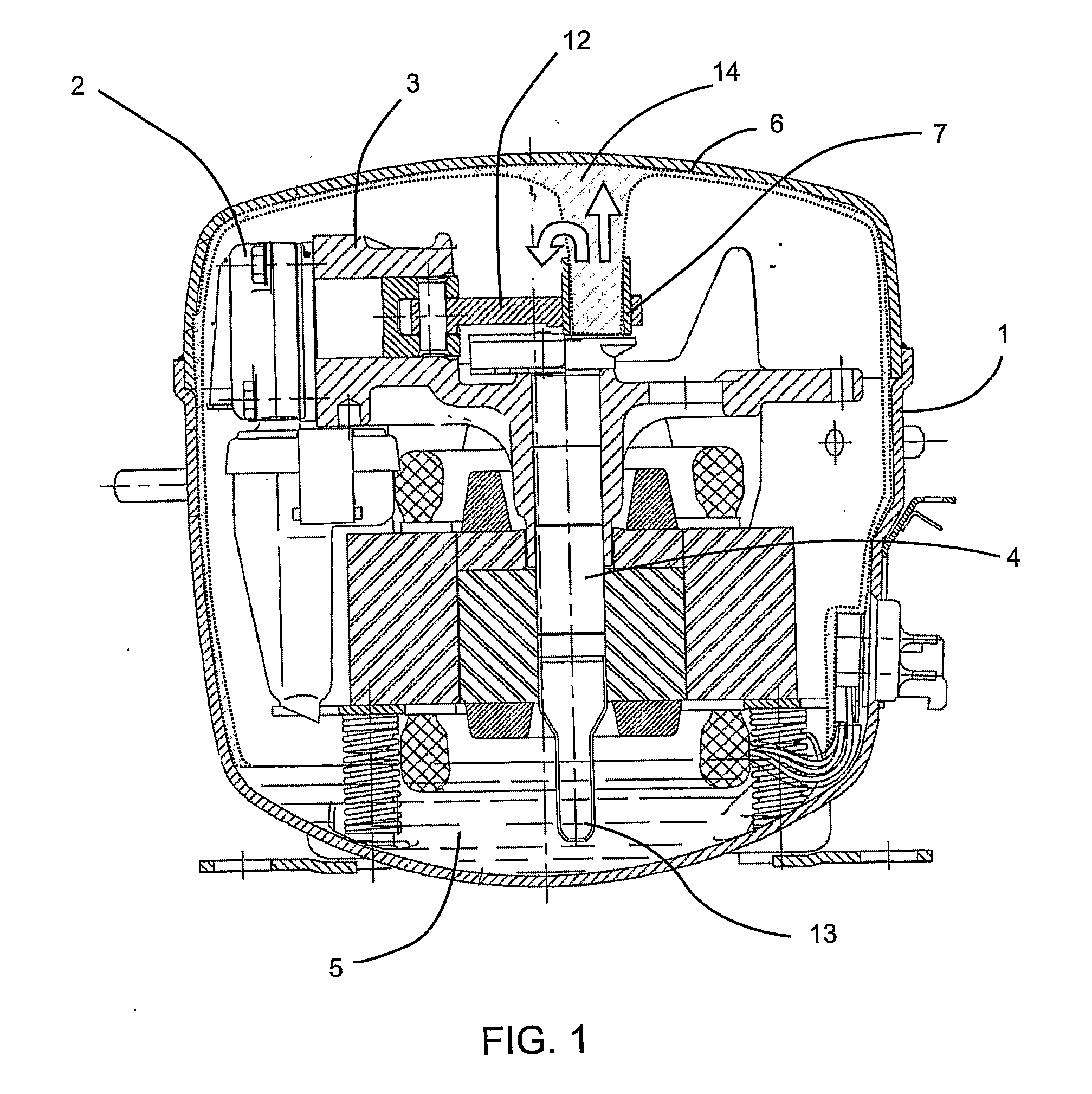

FIG. 1 depicts a compressor of the state of the art merely for comparison purposes with the present invention. This compressor of the hermetic refrigeration compressor type, with reciprocal movement does not have the internal cooling system of the present invention. This compressor is disposed inside the shell 1. The compressor comprises a cylinder that has a cylinder body 3 and a cylinder head 2, and a piston that performs an alternating movement inside the cylinder. In the lower portion of the compressor shell, an oil accumulating region 5 is formed in the shape of a well. The oil accumulating in this accumulation region originally has the purpose of lubricating the compressor parts, reducing the attrition between them and increasing the durability of the compressor.

This refrigeration compressor of the state of the art also has piston drive means, which are responsible for driving the alternating movement of the piston inside the cylinder, compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com