Pouch Machine With Sealer

a technology of sealer and pouch machine, which is applied in the field of pouch machine, can solve the problems of improper sealing, cost and complexity, and subject to wear and maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

While the present invention will be illustrated with reference to a particular pouch machine, with particular components, it should be understood at the outset that the pouch machine can be implemented with other machines and other components

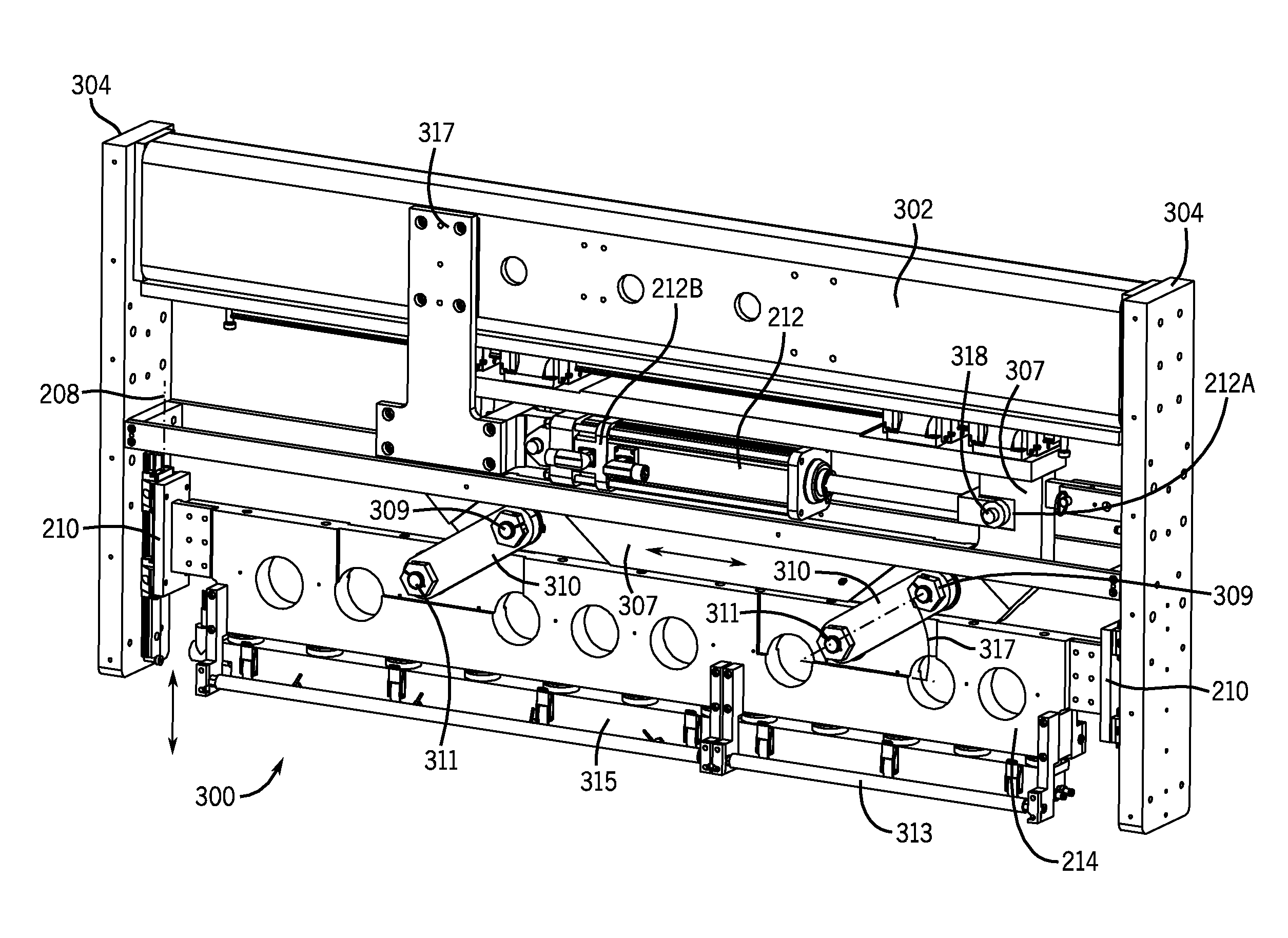

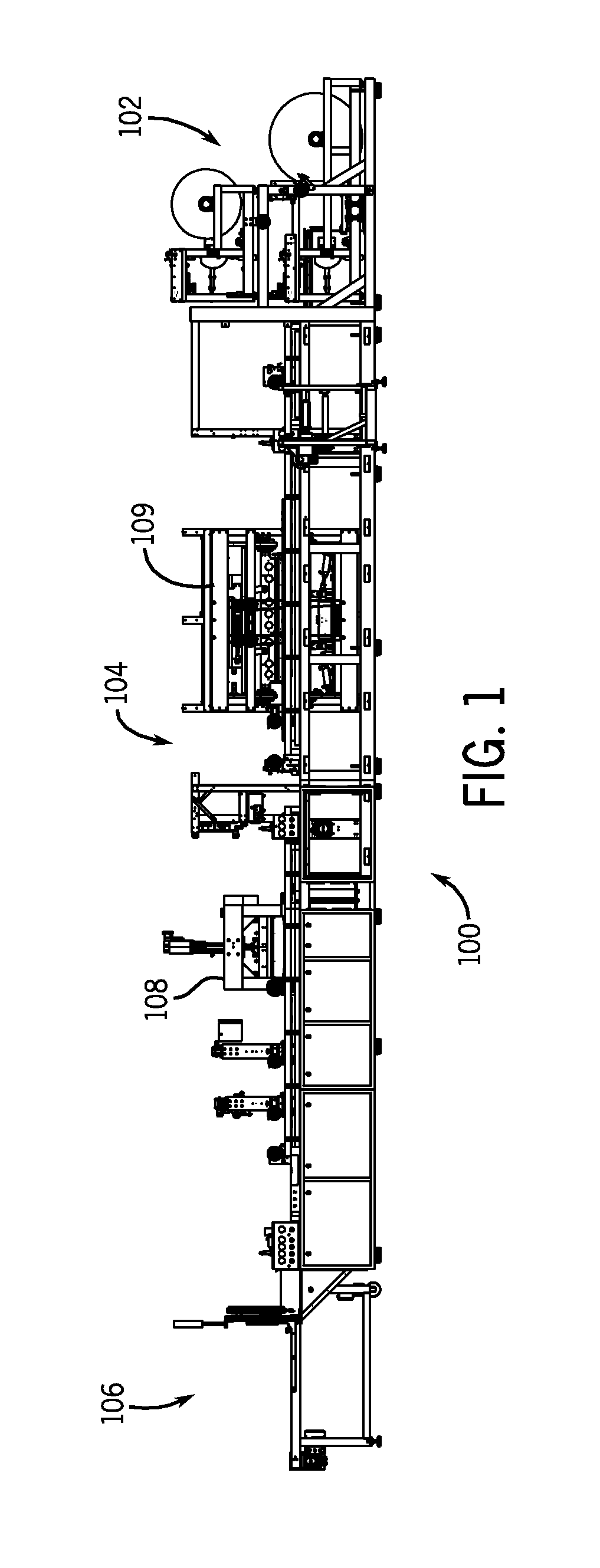

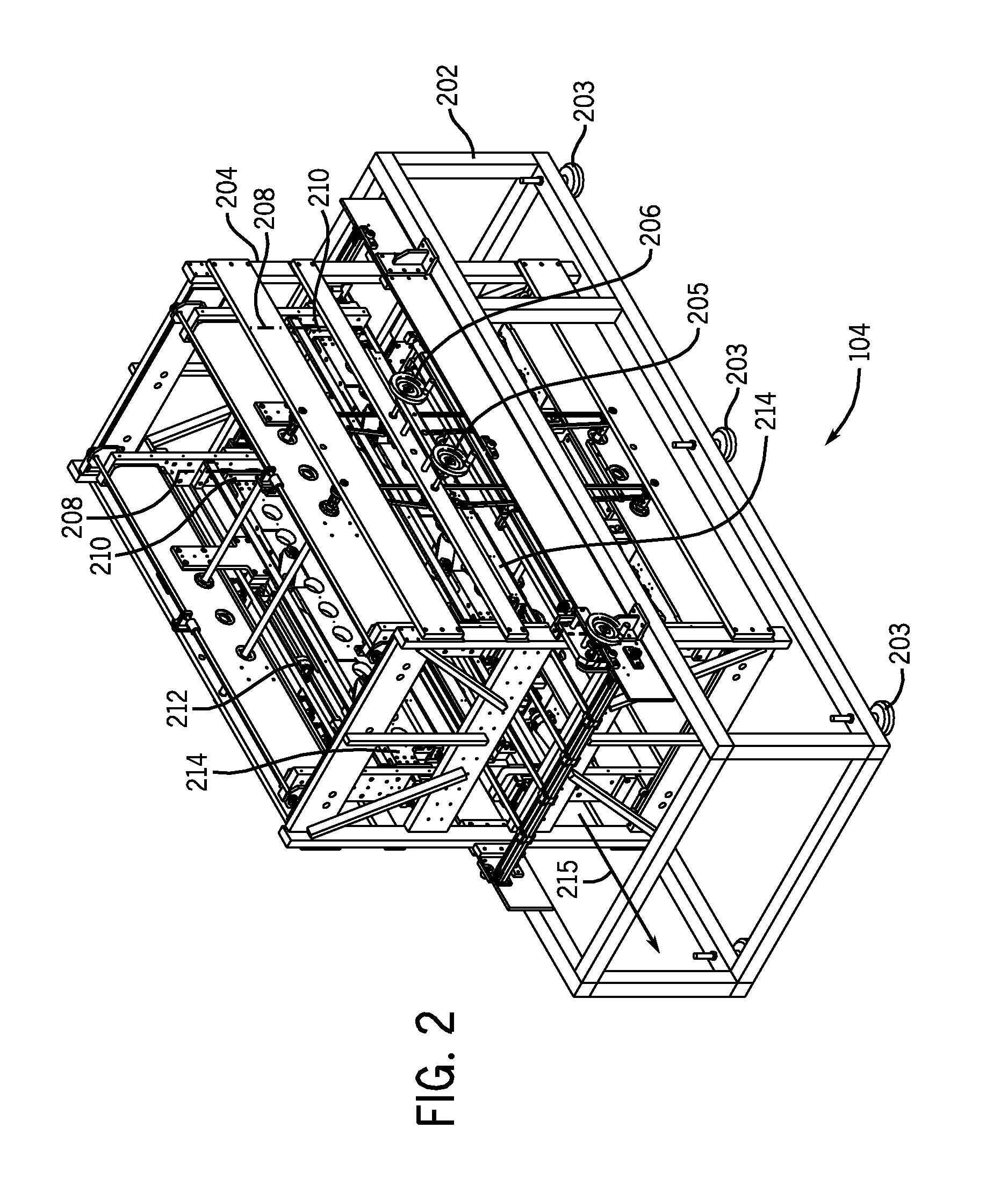

Referring now to FIG. 1, a pouch machine 100 in accordance with the present invention is shown. It includes an infeed section 102, a sealing section 104 and an outfeed section 106. Infeed section, as used herein, is a portion of the machine that receives material to be made into pouches, or partially made pouches, and transports them to a sealing section. Sealing section, as used herein, is the section of a pouch machine where one or more seals are imparted to form or partially form a pouch. Outfeed section, as used herein, is a portion of the machine that receives from a sealing section material that has been at least partially made into pouches, and transports them from the sealing section.

Infeed section 102 receives a laminate (or partially f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| horizontal distance | aaaaa | aaaaa |

| vertical distance | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com