Light guide plate and light source apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

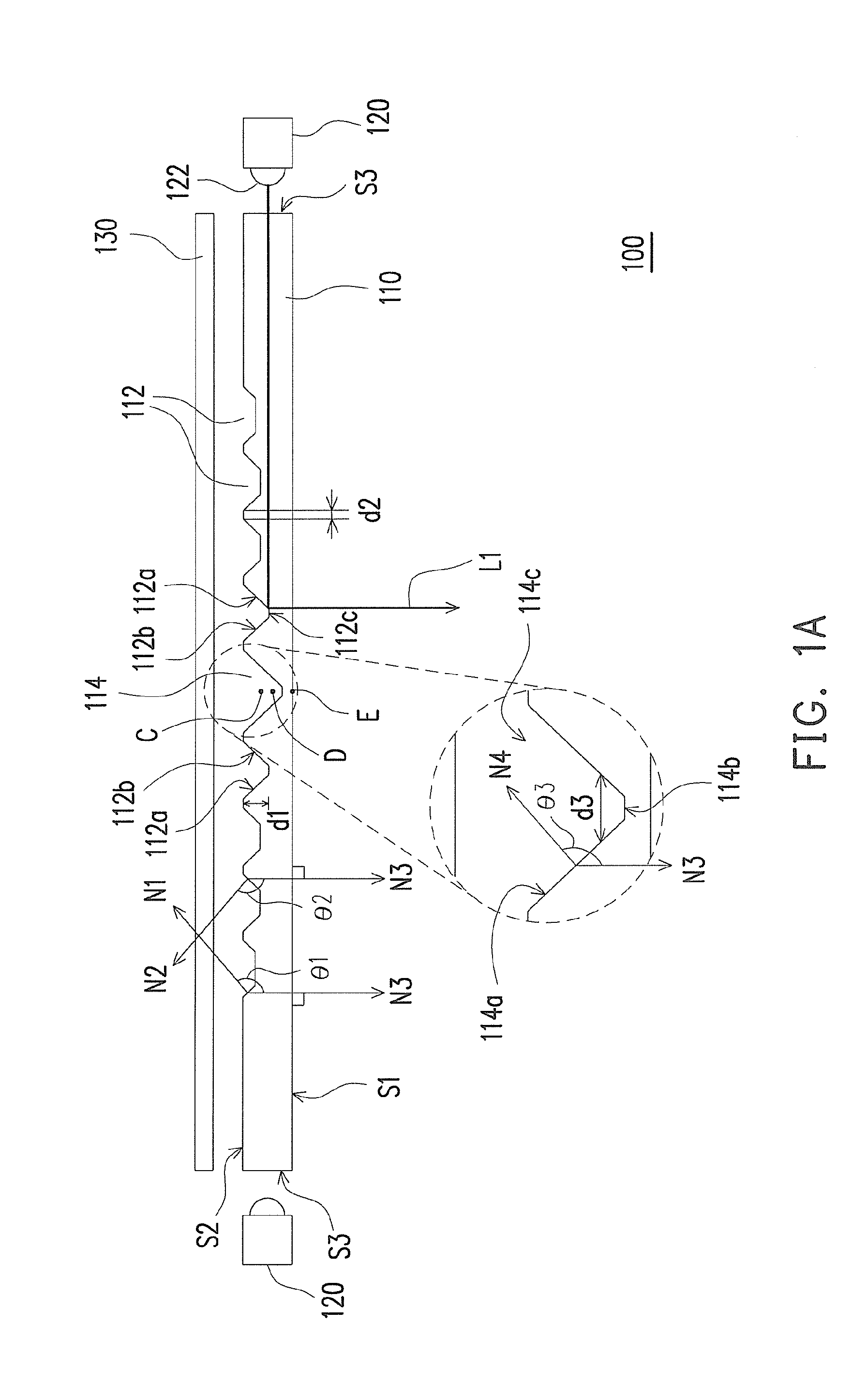

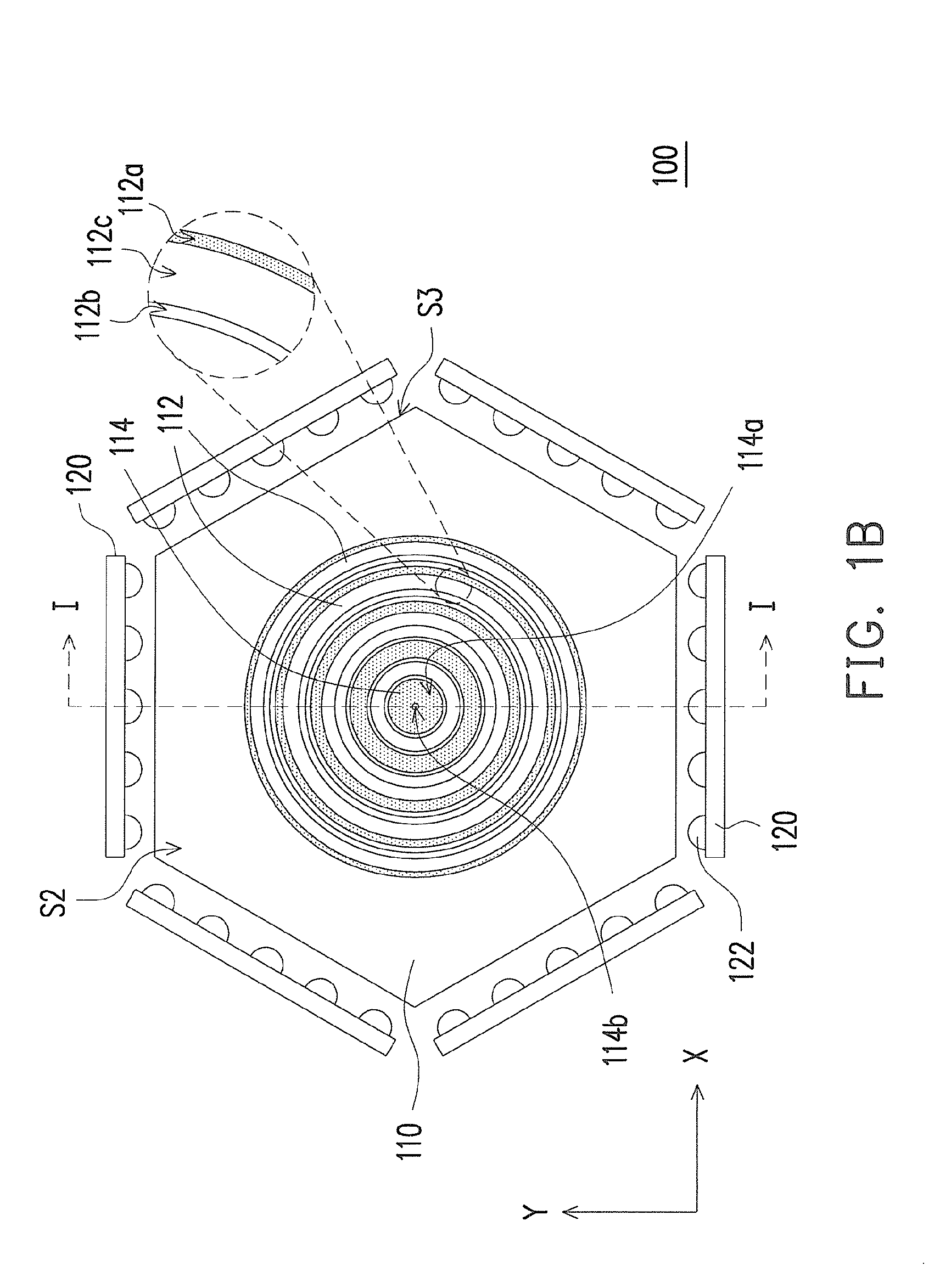

[0025]FIG. 1A is a sectional diagram of a light source apparatus according to the first embodiment of the invention and FIG. 1B is a top view diagram of the light source apparatus of FIG. 1A after removing the reflection sheet thereof, wherein FIG. 1A is a sectional diagram of FIG. 1B along I-I line. Referring to FIGS. 1A and 1B, a light source apparatus 100 includes an LGP 110 and a plurality of light-emitting units 120. The LGP 110 includes a first surface S1, a second surface S2, and a plurality of light incident surfaces S3. The second surface S2 is opposite to the first surface S1, wherein the first surface S1 is a light-emitting surface. The light incident surfaces S3 are connected to the first surface S1 and the second surface S2.

[0026]The light-emitting units 120 are respectively disposed beside the light incident surfaces S3, wherein each of the light-emitting units 120 is capable of emitting a light beam L1. The light beams L1 are capable of entering th...

second embodiment

The Second Embodiment

[0033]FIG. 4 is a top view diagram of a light source apparatus 200 according to the second embodiment of the invention. The light source apparatus 200 is similar to the light source apparatus 100 of FIG. 1B except that the ring-shaped groove 212 of the light source apparatus 200 is a polygon ring, for example, a pentagon ring. In addition, the shape of the LGP 210 may be designed as a pentagon LGP in association with the shape of the ring-shaped groove 212. Other depiction and modification related to the light source apparatus 200 may refer the first embodiment, which is omitted to describe.

third embodiment

The Third Embodiment

[0034]FIG. 5 is a sectional diagram of a light source apparatus 300 according to the third embodiment of the invention. The light source apparatus 300 is similar to the light source apparatus 100 of FIG. 1A except that the ring-shaped groove 312 of the light source apparatus 300 is a groove with triangle-shaped section, the cavity 314 is a triangle pyramid cavity. In other embodiments, the cavity 314 may also be a cone cavity. Other depiction and modification related to the light source apparatus 300 may refer the first embodiment, which is omitted to describe.

[0035]In summary, the embodiments of the invention include at least one of the following advantages or effects. In the embodiments of the invention, since the LGP has a plurality of light incident surfaces and a plurality of ring-shaped grooves, the emitting angle of the light beam may be effectively controlled so as to provide good light-emitting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com