Transfer Device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

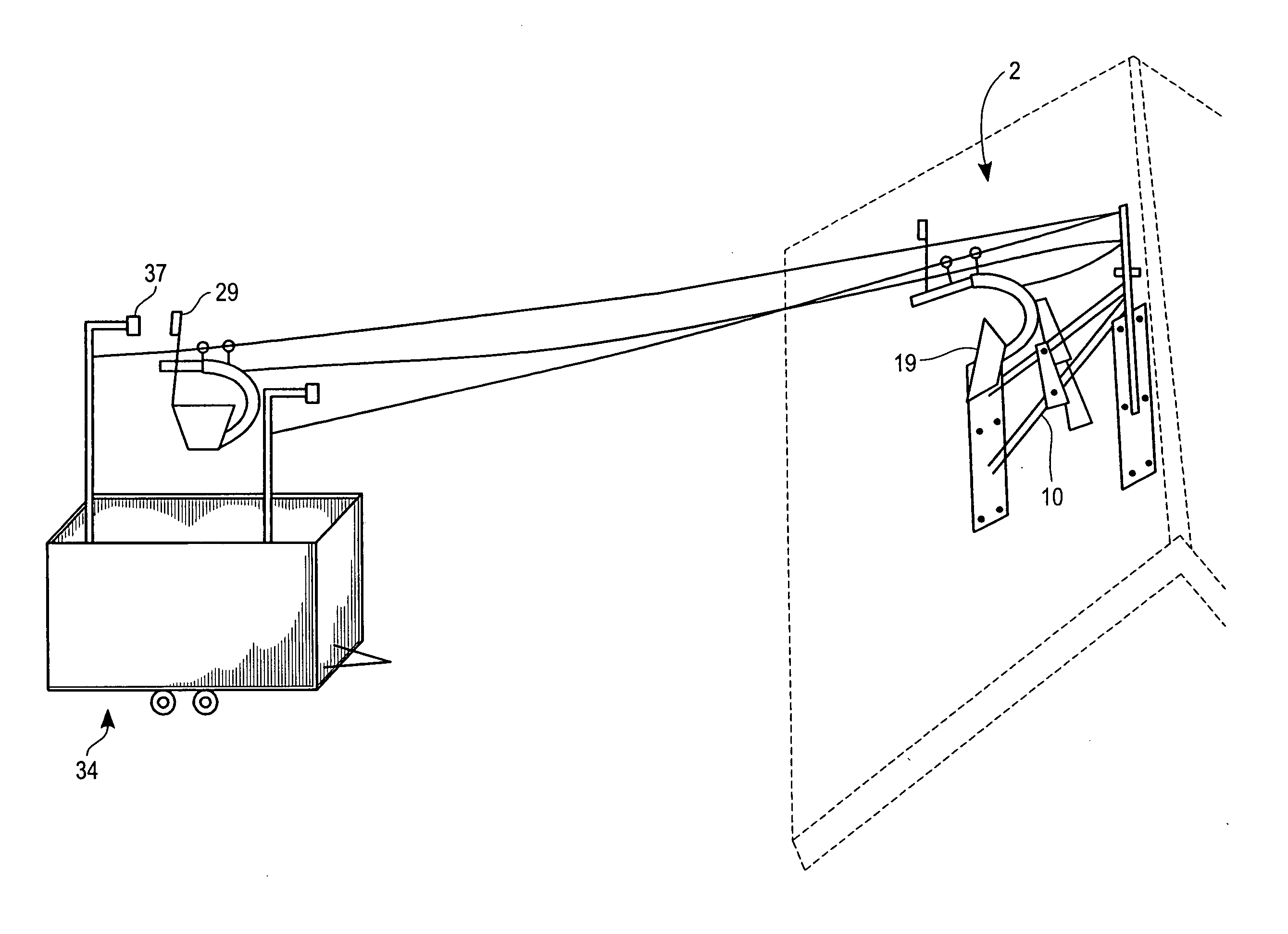

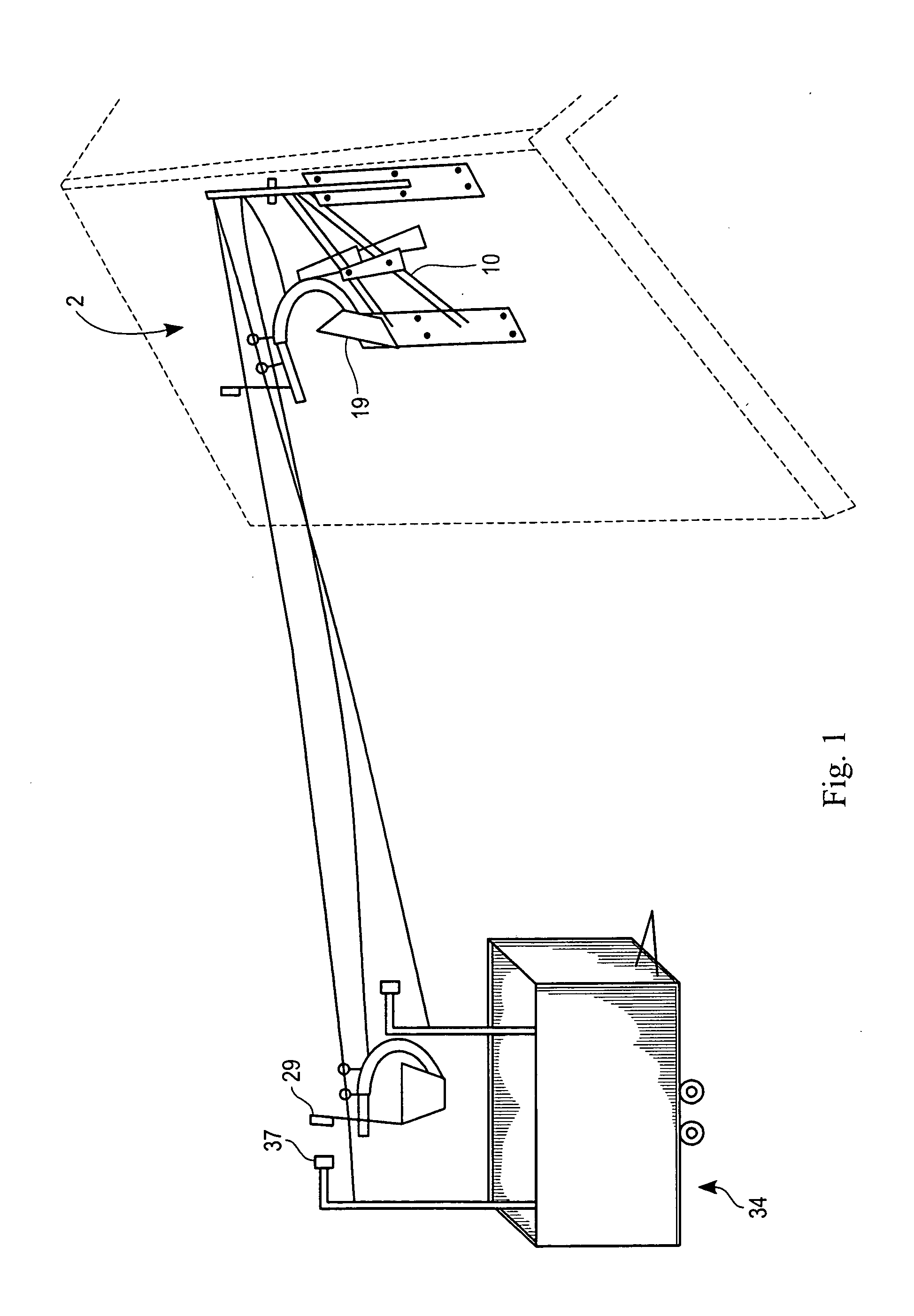

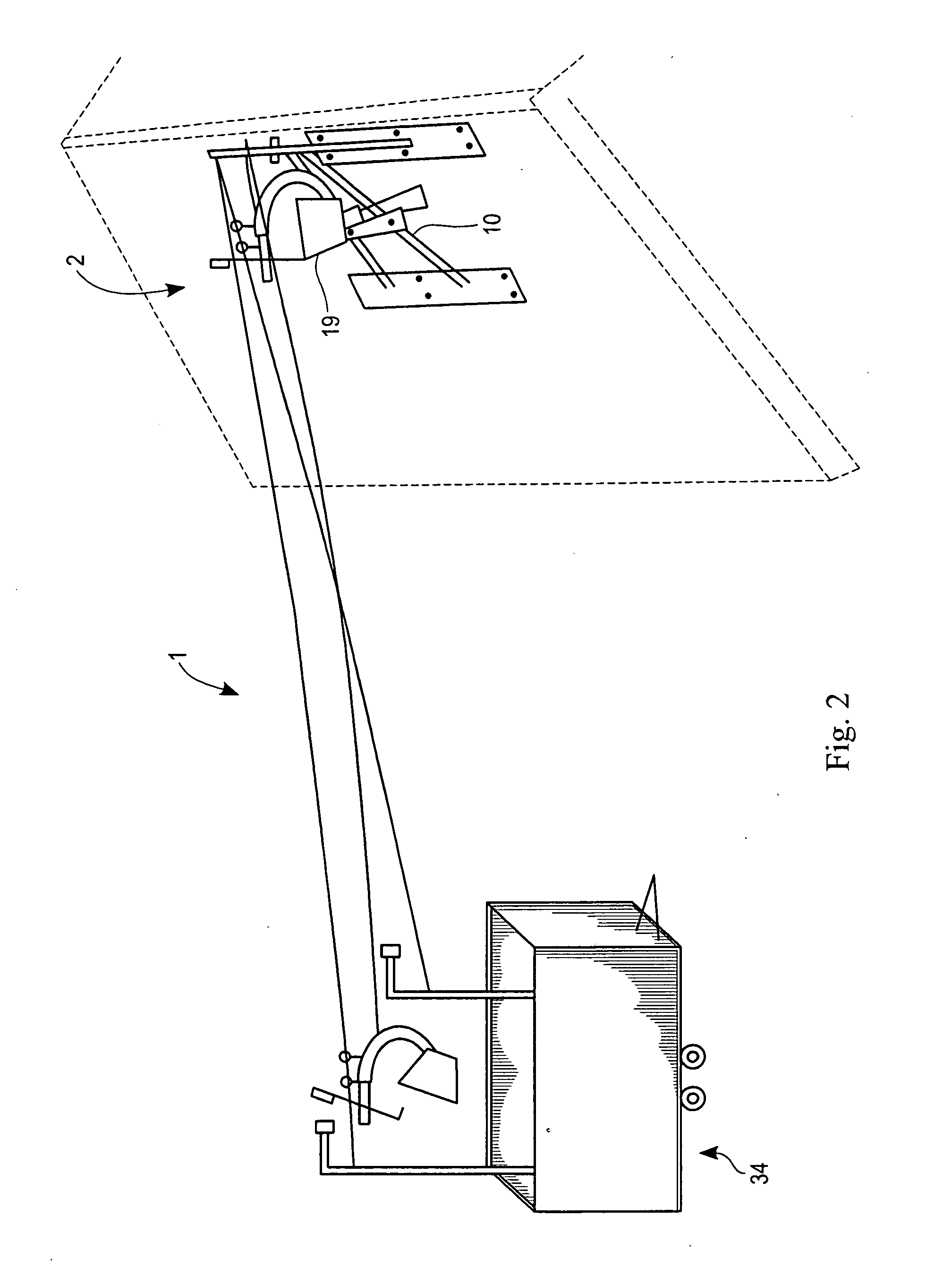

[0070]The transfer device 1 is a device configured and designed to carry roof debris from the top of a roof down to a trash bin 34. The roof fixture 2 is designed to have a sturdy base mounted on a rooftop, such as at a peak of a roof

[0071]The main pole 3 provides a frame to receive an anchoring connection for the support cable 17 and control line 15 at the rooftop. The main pole 3 may be tubing and may comprise of strong, lightweight hard metal. The main pole 3 preferably extends generally vertically from the mount plate 5 which is mounted to the roof such as by nails through nail holes 9. The one or more brace poles 4 can be designed to hold the main pole 3 in a vertical position. The brace pole 4 may comprise of strong, lightweight hard metal. The mount plate 5 is designed to be fastened to the roof deck, while accommodating the main pole 3 and brace pole 4. The mount plate 5 could be made of wood or metal such as aluminum. The swivel bracket 6 is designed for a means of connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com