Method and Apparatus For Building Support Piers From One or Successive Lifts Formed In A Soil Matrix

a technology of soil matrix and support pier, which is applied in the direction of drilling machines and methods, foundation engineering, drilling/well accessories, etc., can solve the problems of increasing the cost of producing piers, the speed with which the process can be conducted, and the depth at which the pier forming process can be achieved economically, so as to achieve the effect of imparting lateral stress on the adjacent soil matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] General Construction:

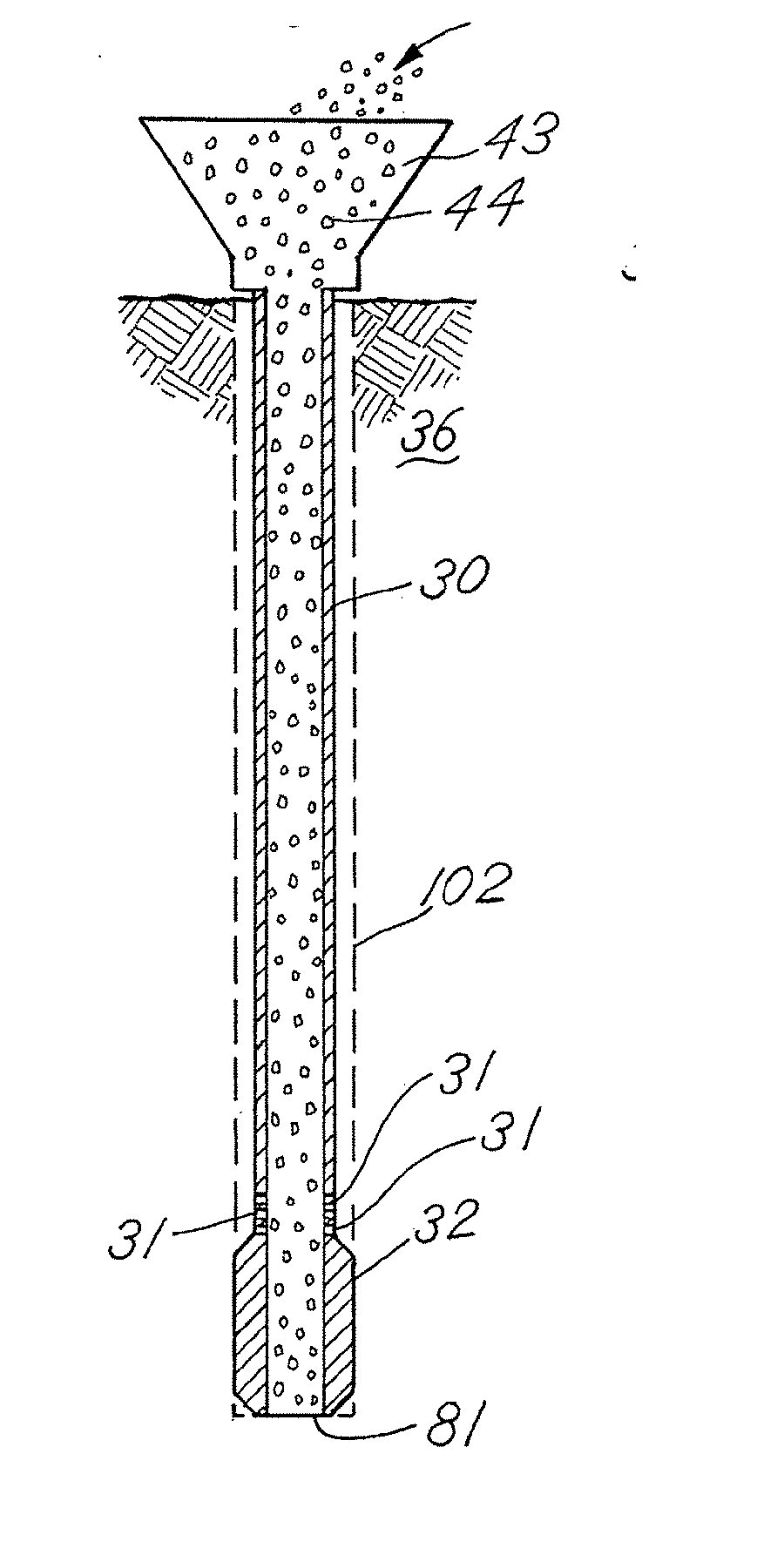

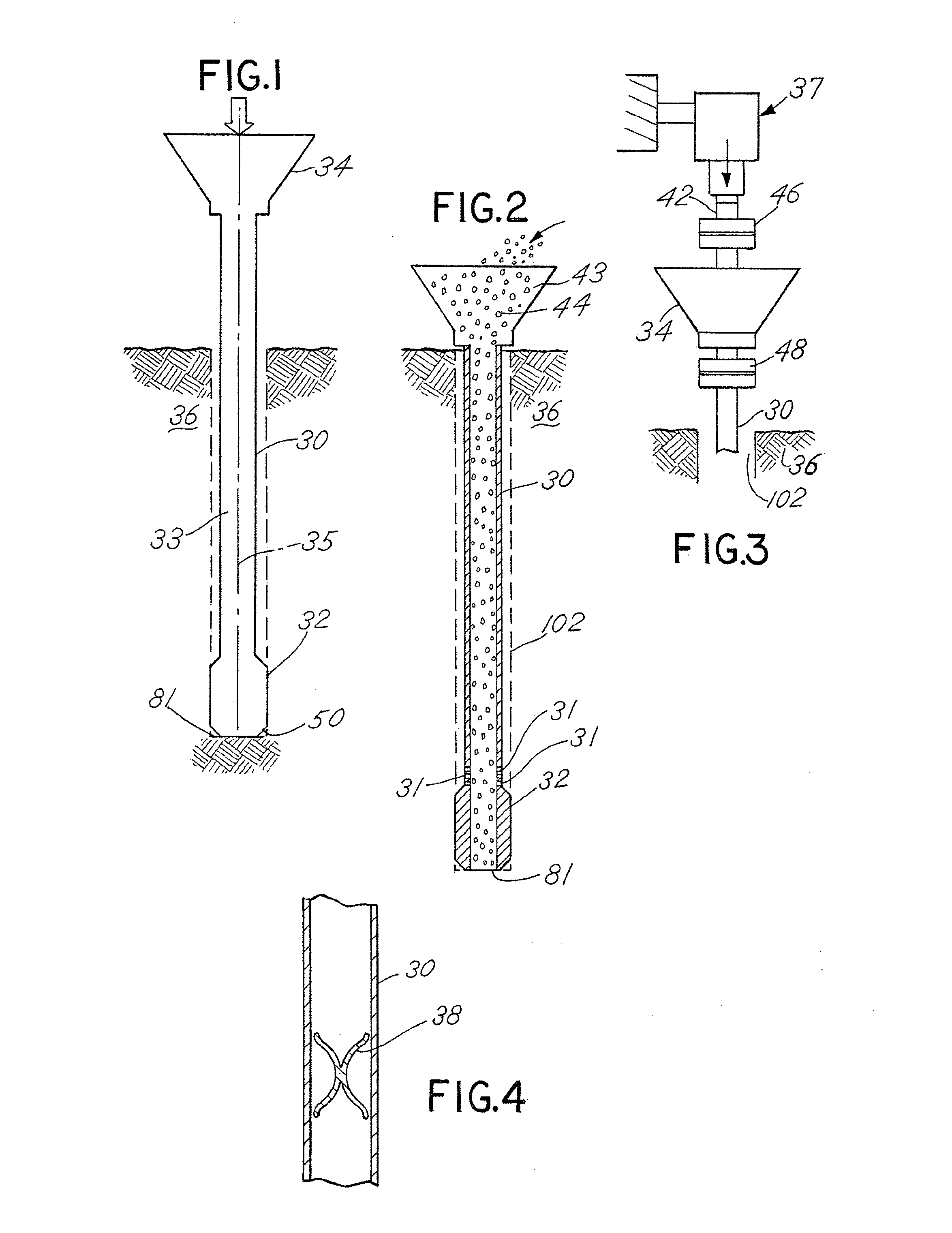

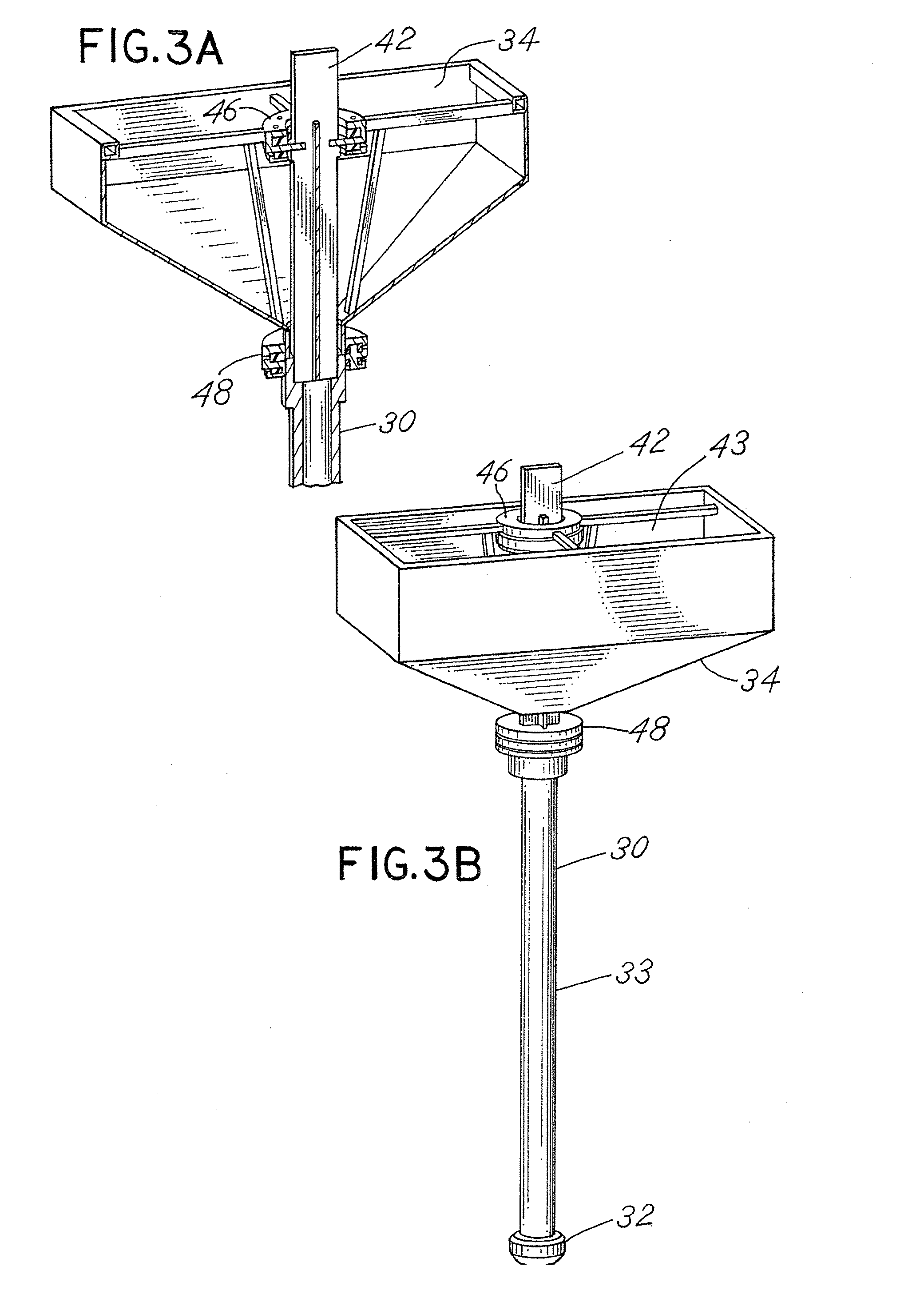

[0079]FIGS. 1, 2, 5, 6, 7, 9, 10, 11, 12, 13, 18, 19, 20 and 23-26 illustrate the general overall method of construction of the pier forming device or mechanism and various as well as alternative sequential steps in the performance of the method of the invention that produce the resultant aggregate pier construction. Referring to FIG. 1, the method is applicable to placement of piers in a soil matrix which requires reinforcement for the soil to become stiffer and / or stronger. A wide variety of soils may require the practice of this invention including, in particular, sandy and clay soils. With the invention, it is possible to construct piers comprised of one or more lifts, utilizing aggregate materials and optionally utilizing aggregate materials with additive materials such as water, cement, sand or grout. The resulting piers have greater stiffness and strength than many prior art aggregate piers, can economically be extended to or built to greater dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com