Automated Immunoassay Apparatus

an immunoassay and automatic technology, applied in the field of automatic immunoassay equipment and enzyme linked immunosorbent assay system, can solve the problems of manual operation system, comparatively expensive equipment, and inability to generally match other manufacturers' equipment, and achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

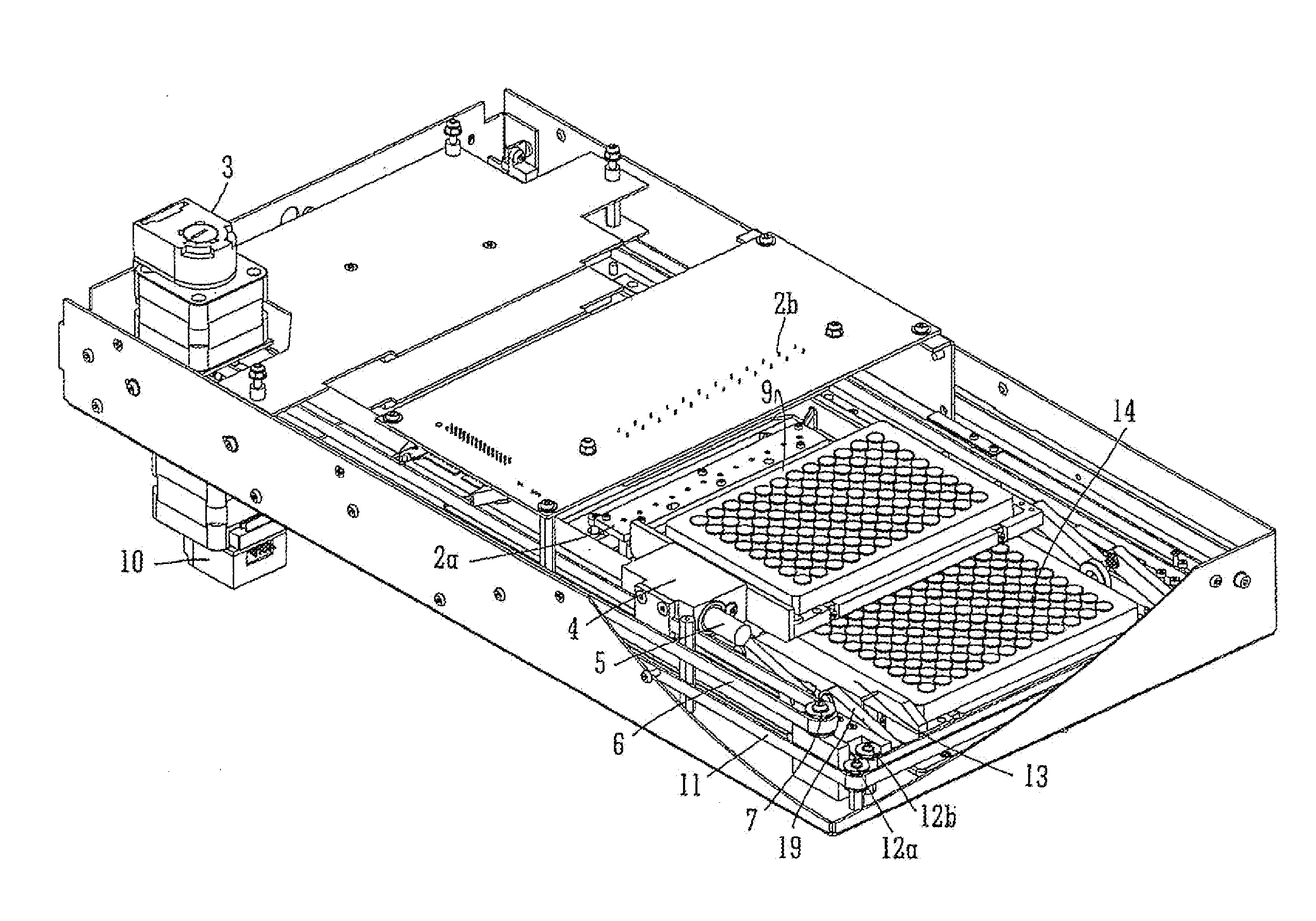

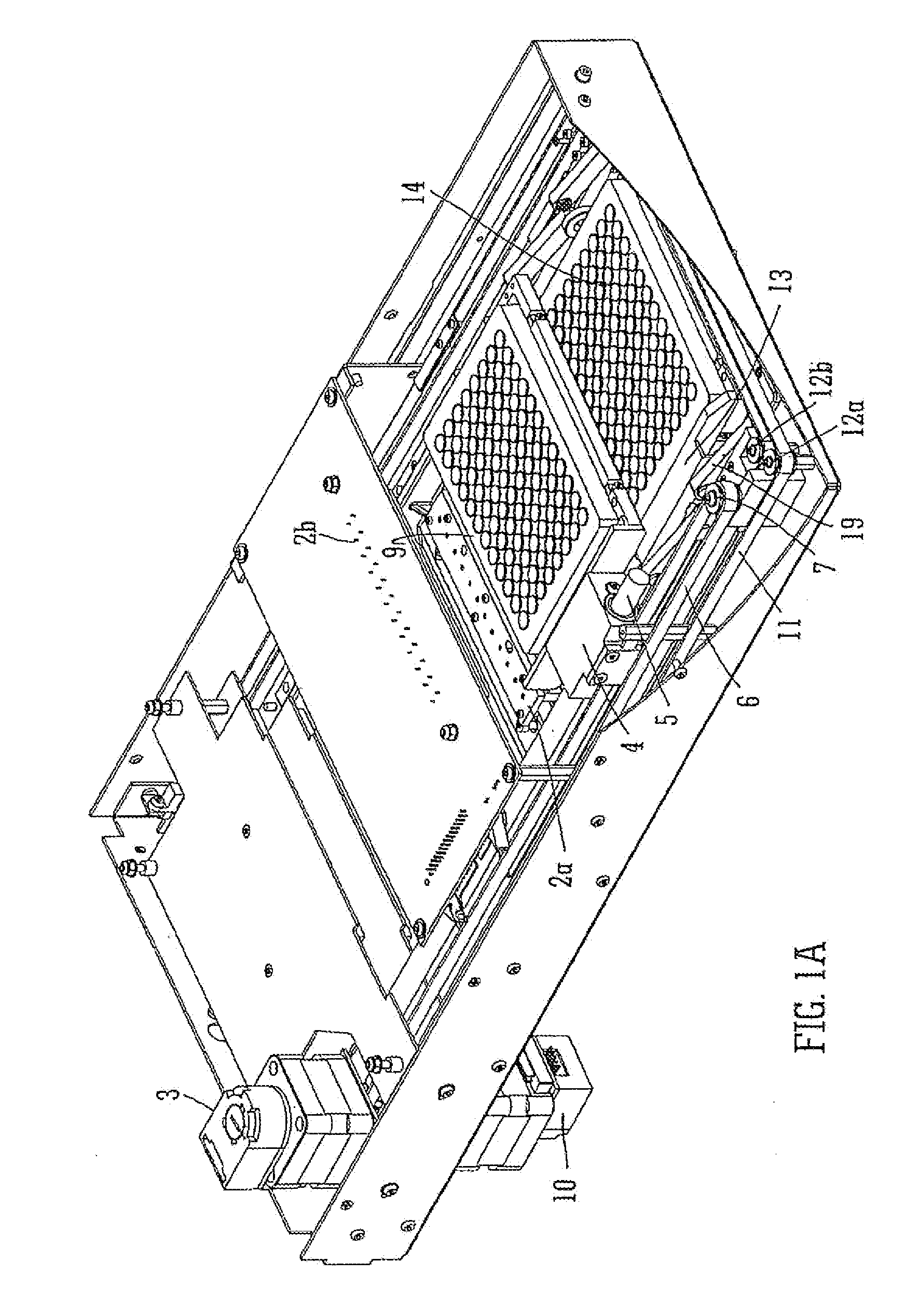

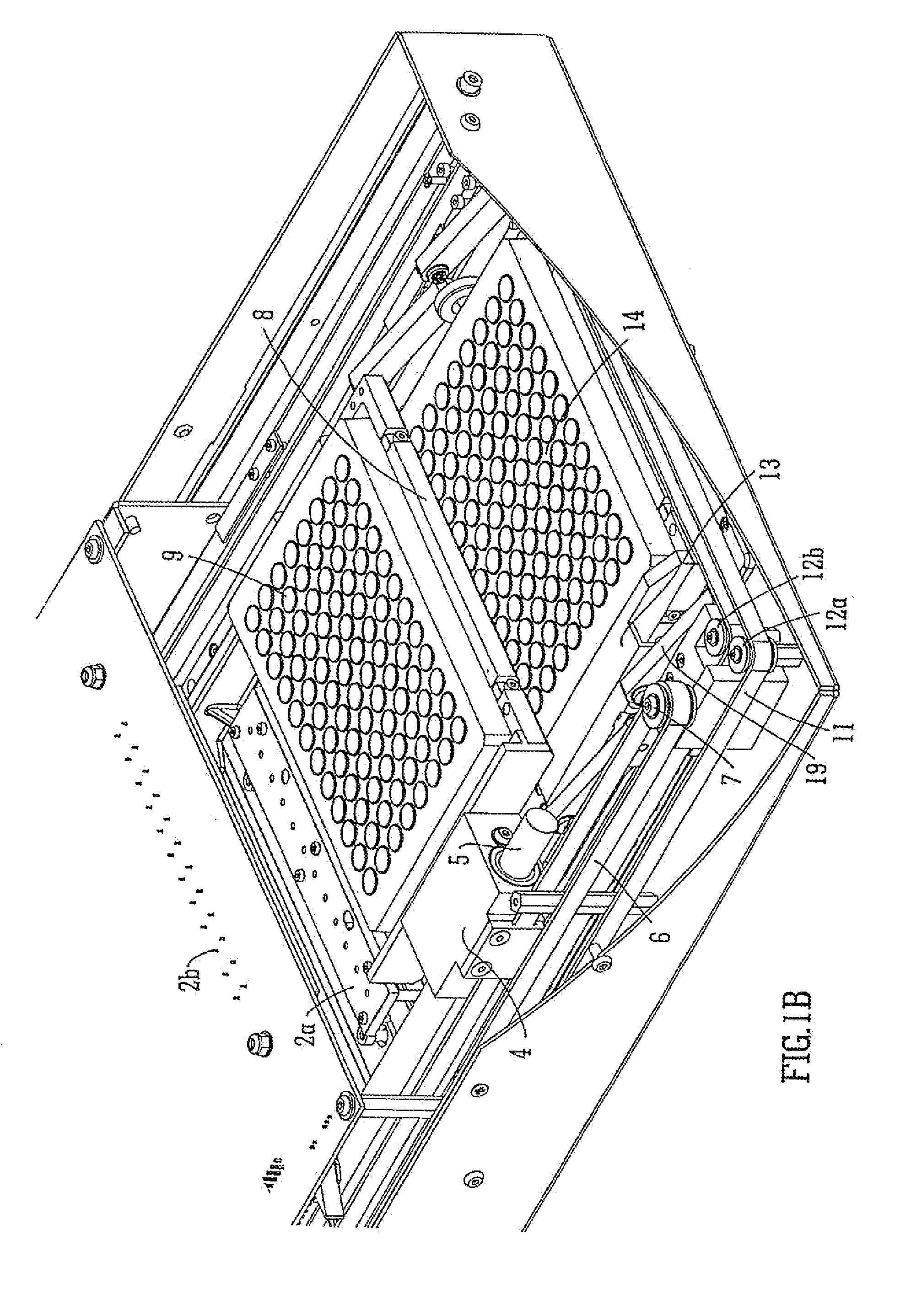

[0138]A first main preferred embodiment of the present invention relating to an immunoassay apparatus for reading two microtitre plates using a single reader device will now be described with reference to FIGS. 1-13B. FIG. 1 shows an automated immunoassay apparatus 1 according to a preferred embodiment which preferably comprises a single optical reading device 2a, 2b for reading two microtitre plates 9, 14. The microtitre plates 9, 14 are preferably loaded at the front of the apparatus 1 and are preferably translated over or through the optical reading device 2a, 2b in order to be read by the Optical, reading device 2a, 2b. The. optical reading device 2a, 2b preferably comprises a strip or line of twelve photo-emitters or photodiodes 2a as shown in FIG. 1A. The light emitters are preferably positioned below a microtitre plate and the microtitre plate preferably passes above or over the light-emitters, A strip or line of photodiodes 2b is preferably arranged or positioned above the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com