Drop and slide mechanism for use with dunnage conversion machine and method

a dunnage and conversion machine technology, applied in the field of dunnage conversion machines, can solve the problems of difficult or time-consuming for packers to replenish the supply, difficult access to the conversion machine and/or stock material supply to inspect and repair the machine, or to replenish the supply of stock material, etc., to achieve the effect of convenient access to an elevated dunnage conversion machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

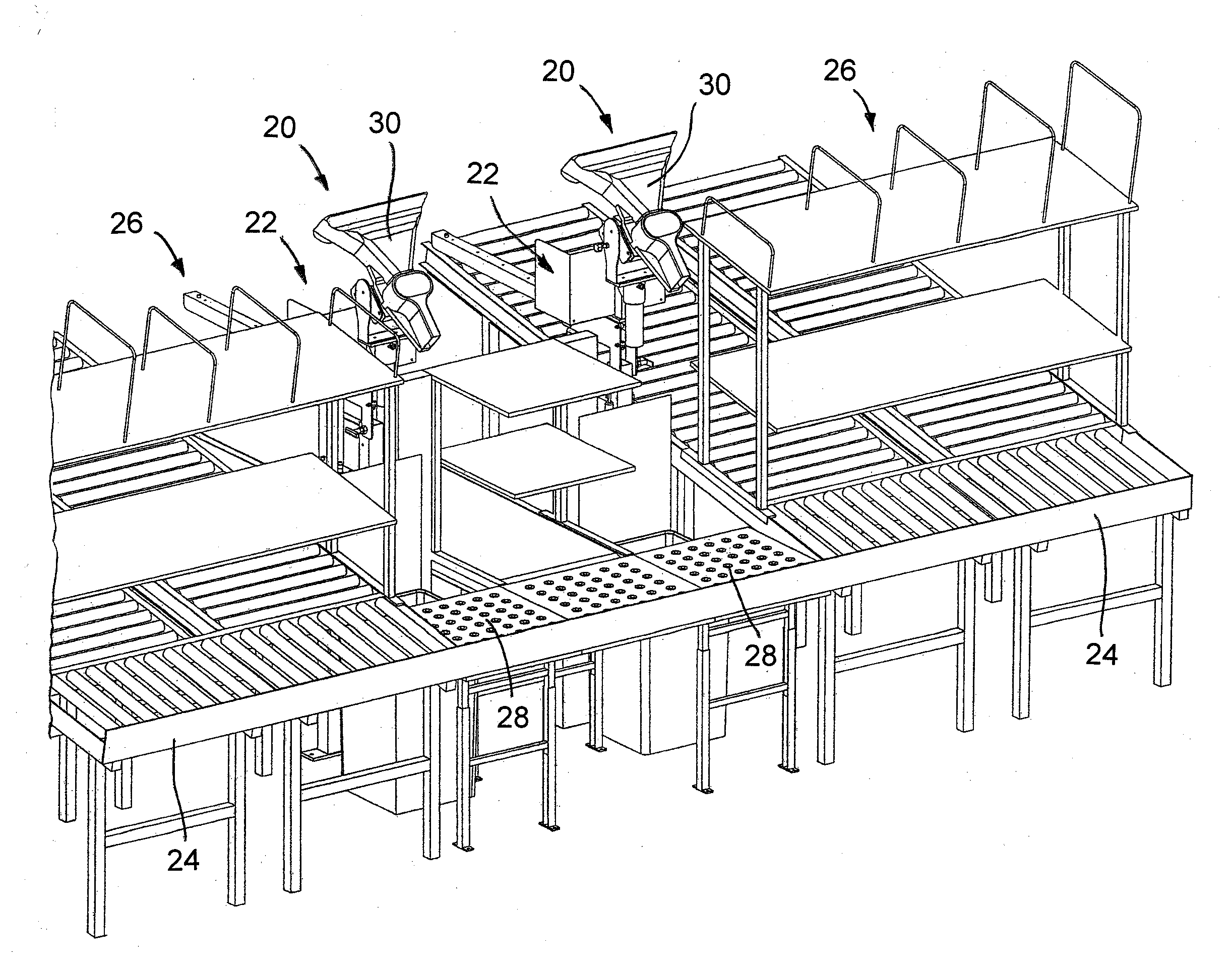

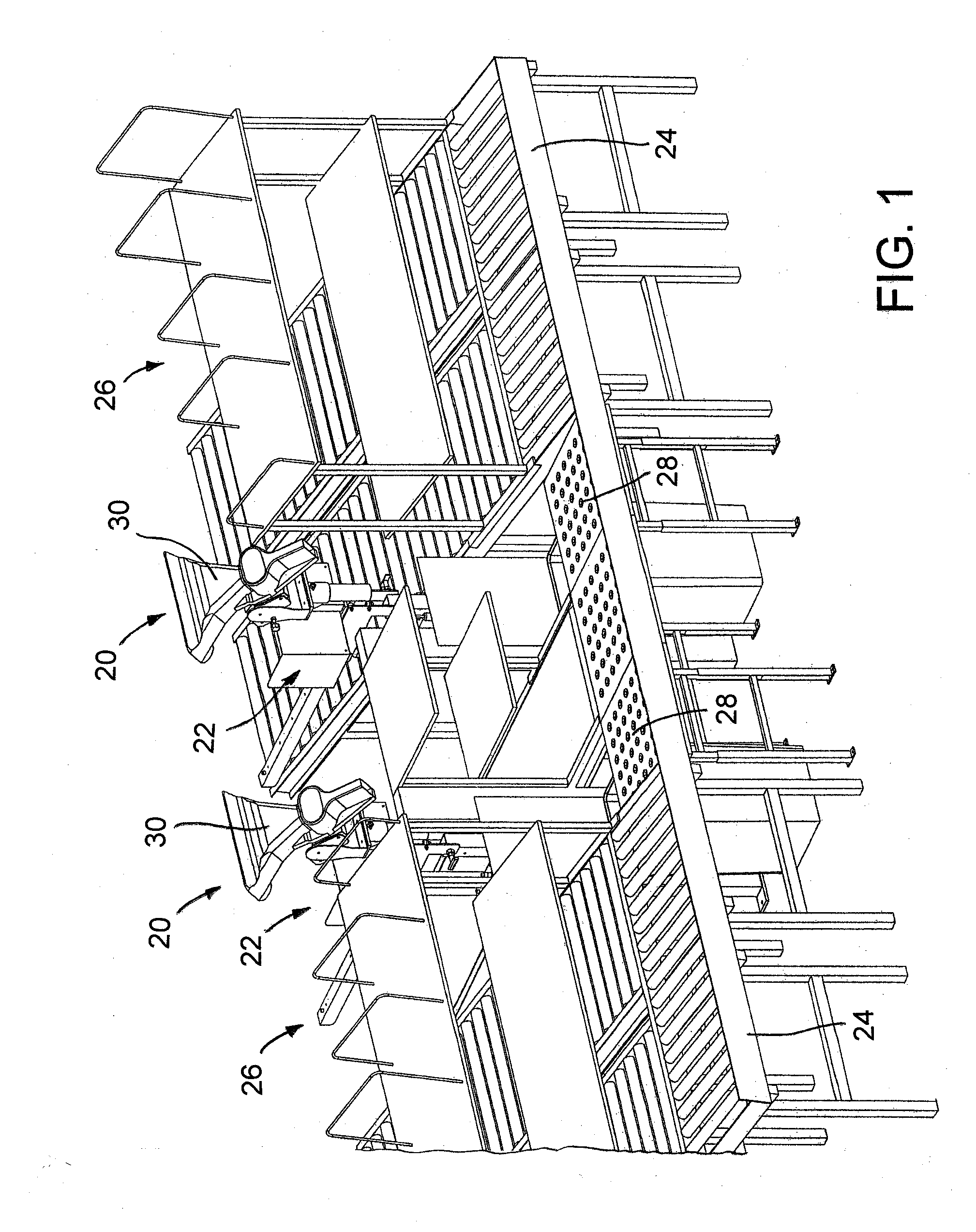

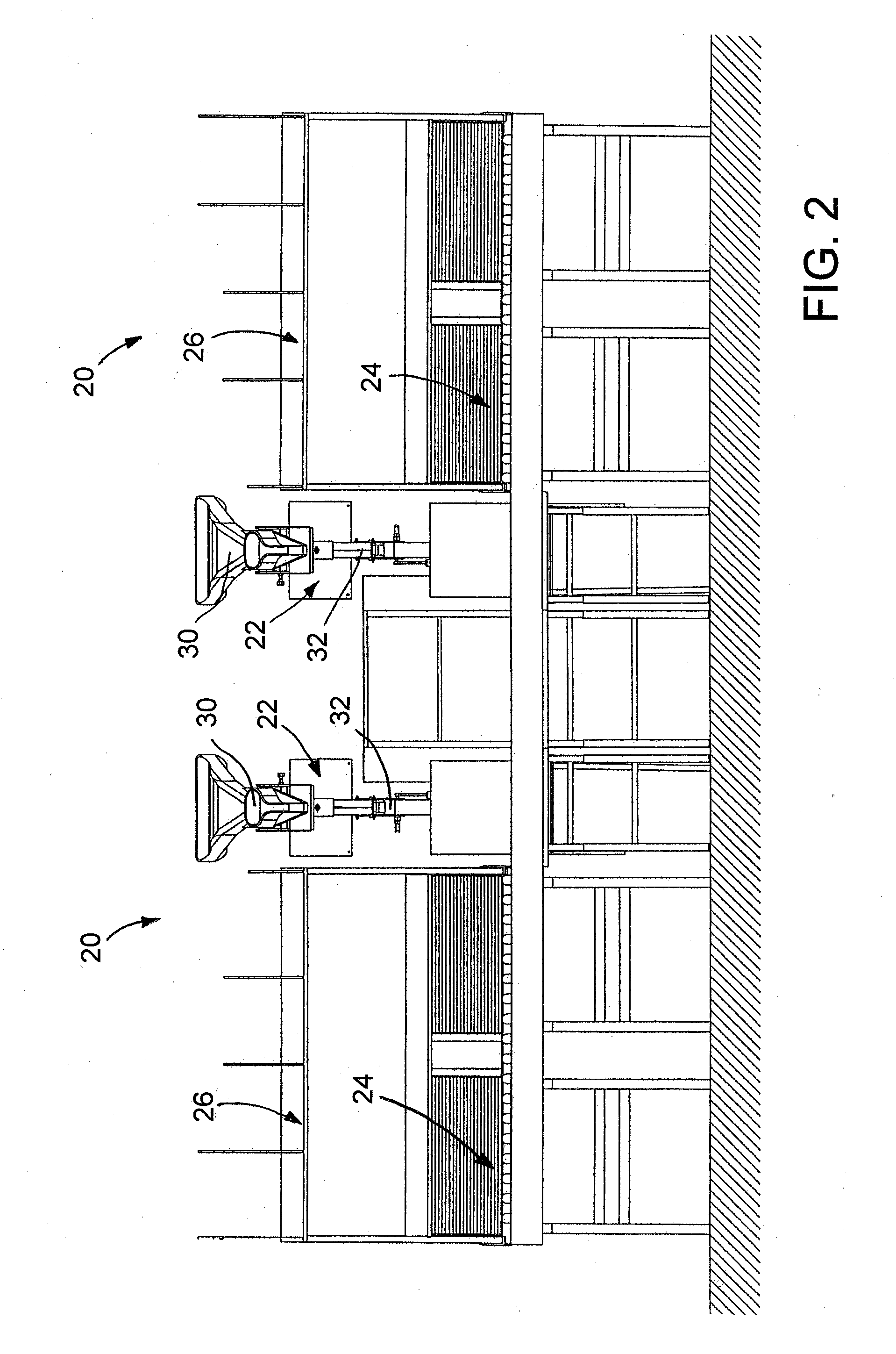

[0023]The present invention provides a way to inspect or load a supply of stock material for a dunnage conversion machine when the support for the stock material supply is mounted at an elevated position above a work surface, such as a conveyor or a table. The conversion machine, also referred to as a converter, typically is mounted about head-high above the work surface to dispense dunnage downward to a box or other container. To load the supply of stock material, the packer pulls the stock material support forward, which causes the stock material support to drop to a loading position where the stock material support is lower and closer to the packer. When pulled forward, the weight of the stock material support extended on a slide overcomes an upward bias to lower the stock material support to a more convenient height closer to the packer for loading, inspection, maintenance, repair, etc. When the packer pushes the stock material support back, away from the packer, a biasing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com