Dual-purpose spin dry mop bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

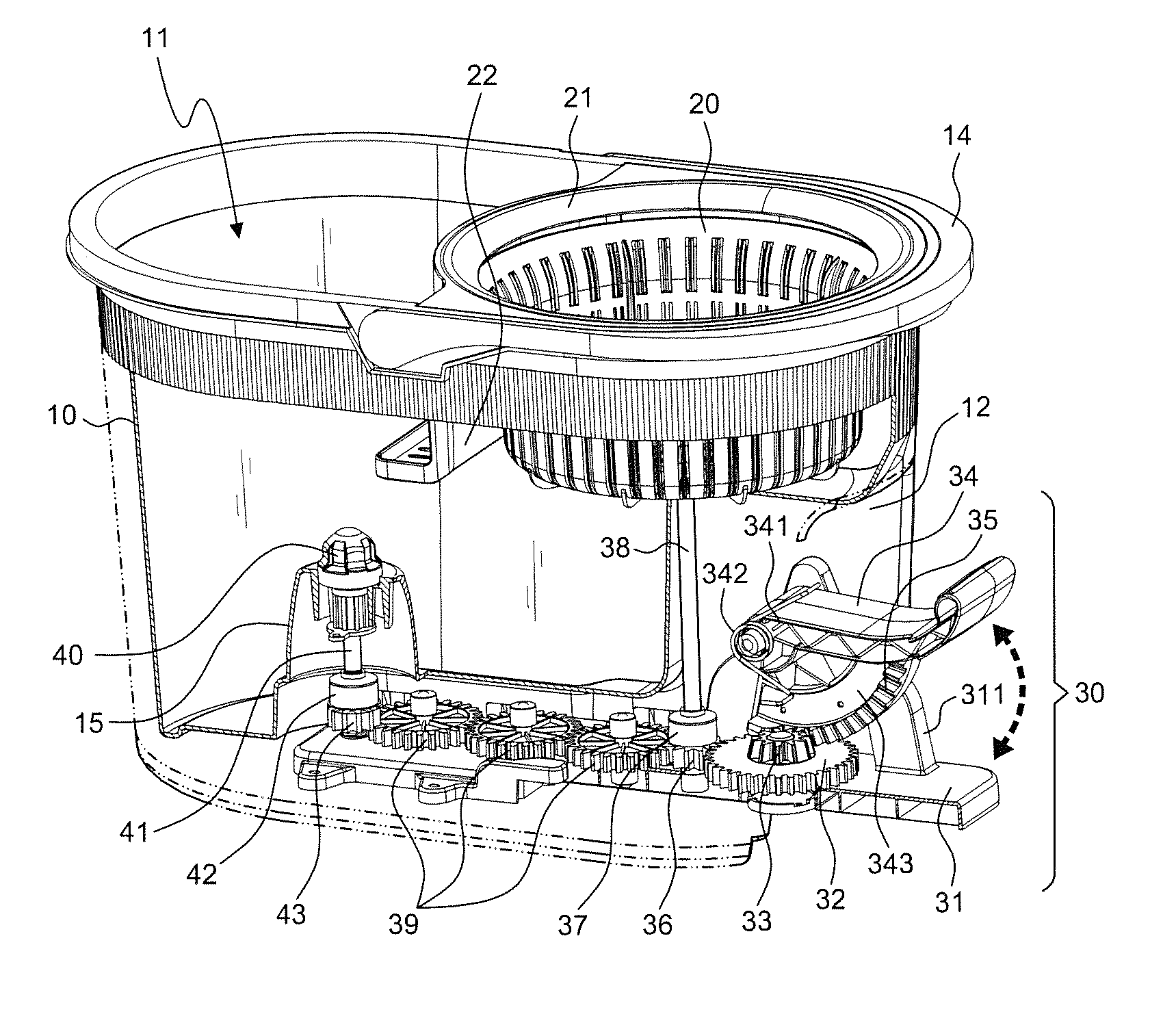

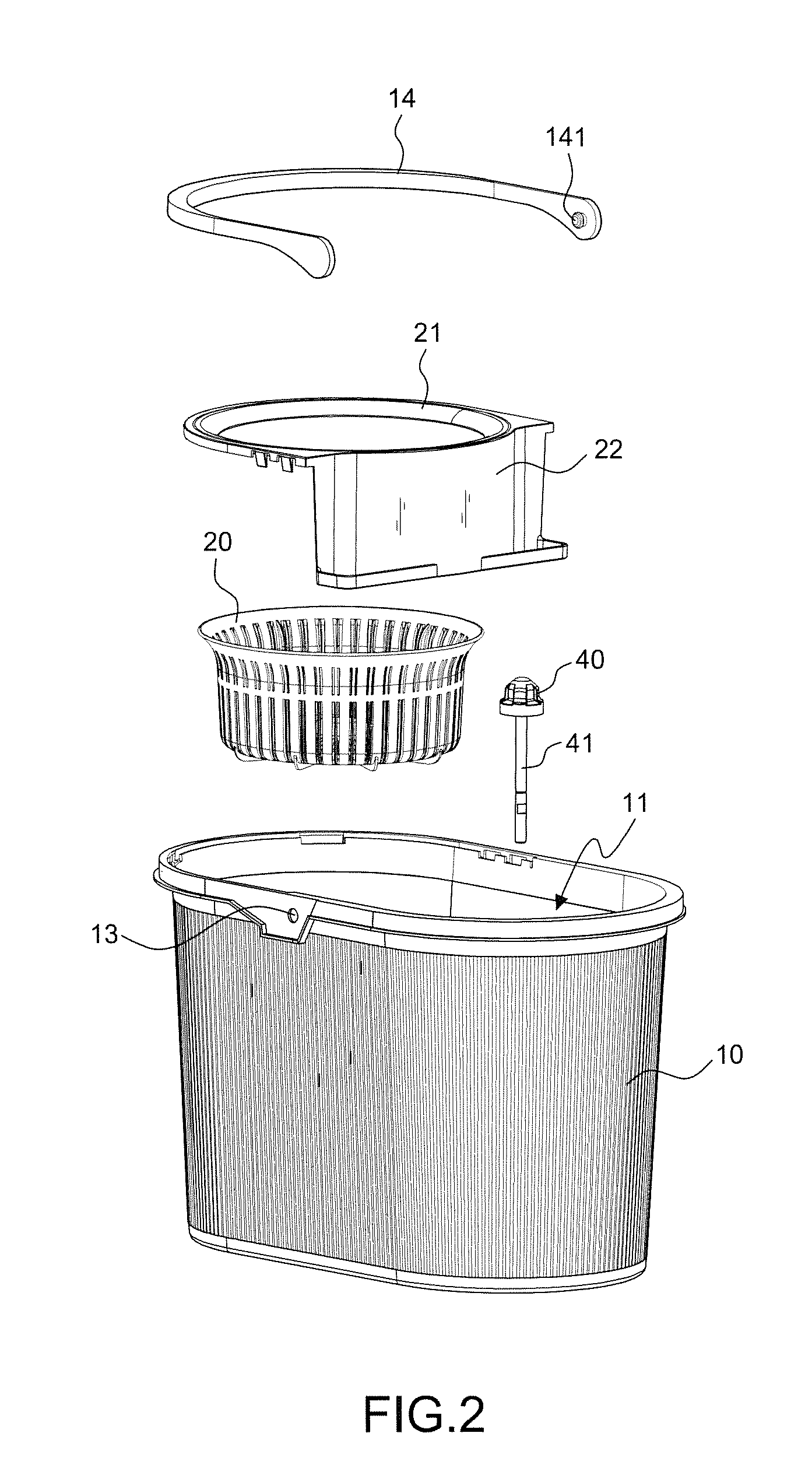

[0021]Referring to FIGS. 2 to 7, a dual-purpose spin dry mop bucket in accordance with the present invention comprises a housing 10 includes a top open side 11, a recessed accommodation area 12 in a front part of a bottom side of the housing 10, a driving mechanism 30 mounted in the recessed accommodation area 12 and adapted for rotating a spin basket 20. In this preferred embodiment, a carrying handle 14 as shown in FIG. 2 arranged at the top side of the housing 10. The carrying handle 14 is an arched bar having a pivot rod 141 located on each of the two distal ends and respectively pivotally coupled to a respective pivot hole 13 at the housing 10.

[0022]With reference to FIGS. 2 and 3, a water retaining ring 21 is mounted at the top side of the spin basket 20 mounted in the housing 10 and the recessed accommodation area 12, having a water baffle 22 downwardly suspending at one side for stopping water from splashing on the surroundings outside the housing 10.

[0023]With reference to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com