Absorbent Article Having Surface Visual Texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

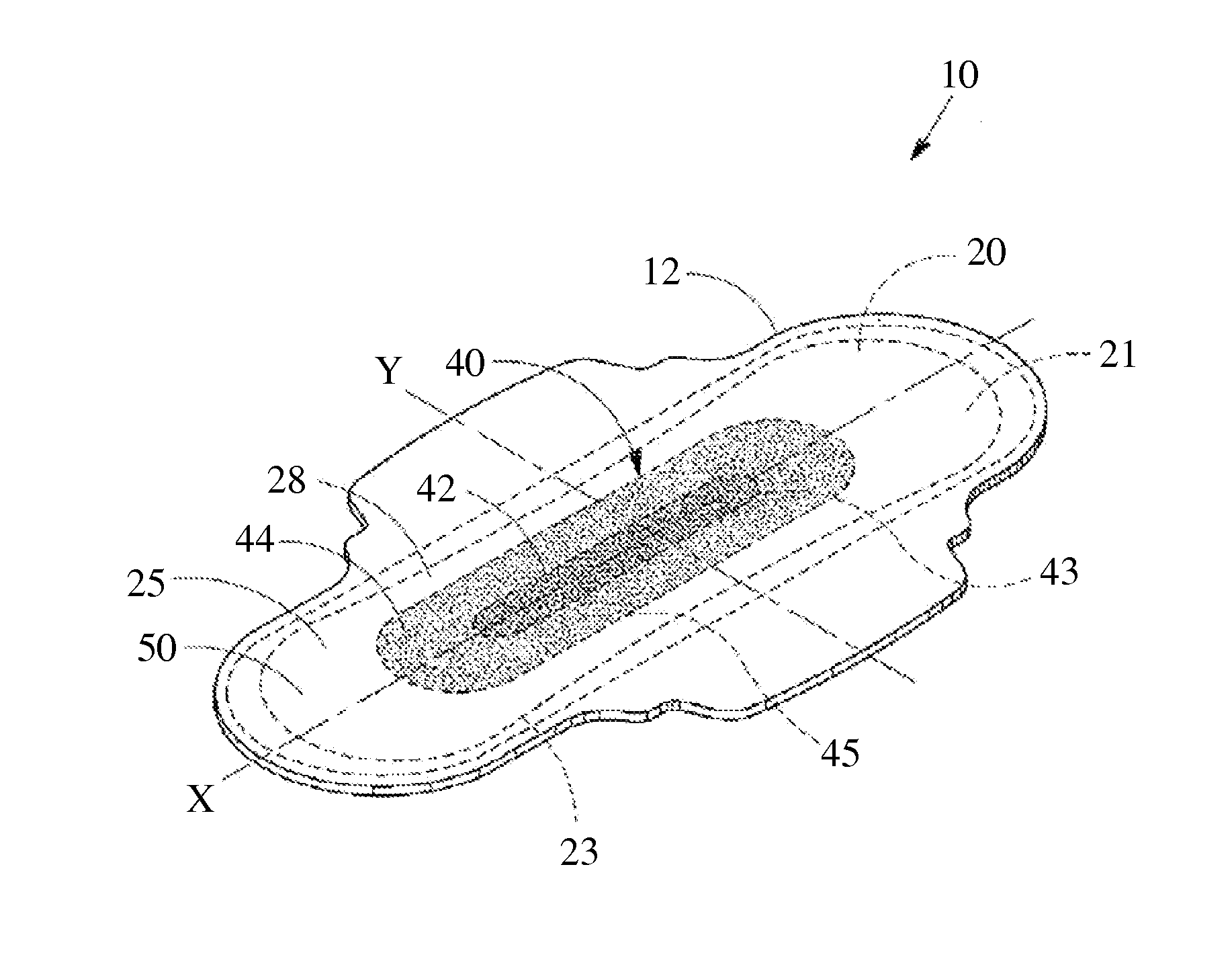

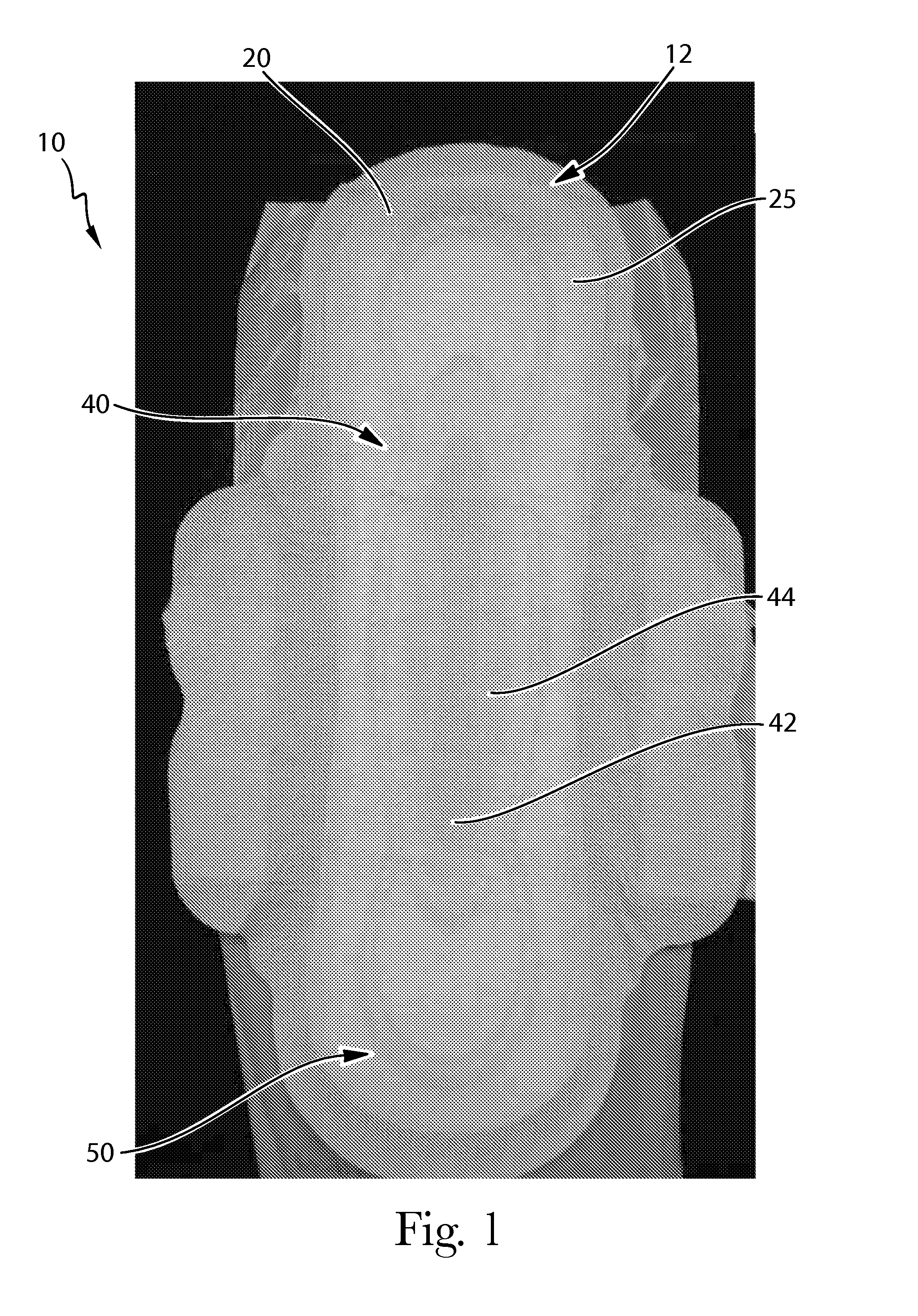

Image

Examples

example 1

Measure of Visual Texture

[0151]Example 1 shows the visual texture of the following sanitary napkin products:

TABLE 1Products testedProductNameDate of PurchaseCountryFIGURE1Inventive Sample 112Always Ultrathin2010Russia5with DriWeave3Always Ultrathin2010U.S.A.9with DriWeave4StayFree DryMax2009U.S.A.13Ultrathin5U by Kotex Regular2010U.S.A.176Kotex Supreme2007Colombia217Nosotras Invisible2008Colombia258ABC with Supsoft2006China29Topsheet9Femline Maxi Long2009Canada3310Inventive Sample 237

[0152]Each product was tested as set forth in the visual texture method above. For samples 1-6 and 9-10, five duplicate samples were tested. For samples 7 and 8, three duplicate samples were tested.

[0153]The data were collected from ROIs which were 400×1,000 pixels in size at a resolutions of 39 microns per pixel, covering 15.6 mm×39 mm of the topsheet in each image, (which is 608.4 square mm or 6.084 square cm).

TABLE 2Visual texture measurement of Products 1-10Average Number ofAverage Mean% Total Objec...

example 2

Sample Parameters

[0155]Aperture, microtexture, thickness, open area, land area, porosity, titanium dioxide level, and land area width for samples 1, 2, 3, and 10 were determined as set forth in Table 3.

TABLE 3Sample ParametersParameter / TopsheetSample 10Sample 1Sample 2Sample 3Macro Aperture DimensionsHeight0.8-1.1mm0.6mm0.65mm1.40mmMaximum diameter in top1.6 mm-1.9 mm1.2 mm-1.4 mm0.8-0.9mmHard to definesurfaceSpacing (Center-to-Center)2.2mm1.8mm1.0mm2.1mm# / sq in 160 225 625 150Microtexture DimensionsHeight0.060mm0.060mm0.020-0.025mm0.100-0.150mmAspect ratio 0.6 0.60.3-0.41.1-2(height / diameter)Spacing (Center-to-Center)0.20mm0.20mm0.12mm0.25mm# / sq in16000 16000 4600010000Film Thickness (gauge)0.9mil0.9mil1.0mil1.05milOpen Area 3%20%24%Not DeterminedLand Area37%34%31%Not DeterminedPorosity (ASTM 737-96)100-220m3 / m2 / min154-265m3 / m2 / min275m3 / m2 / min184m3 / m2 / minTiO2 Level 4% 4% 4%4%Land Area Width21mil18mil7milNot Determined

[0156]Dimension measurements were made by computer aided ...

example 3

Measure of Open Area and Land Area

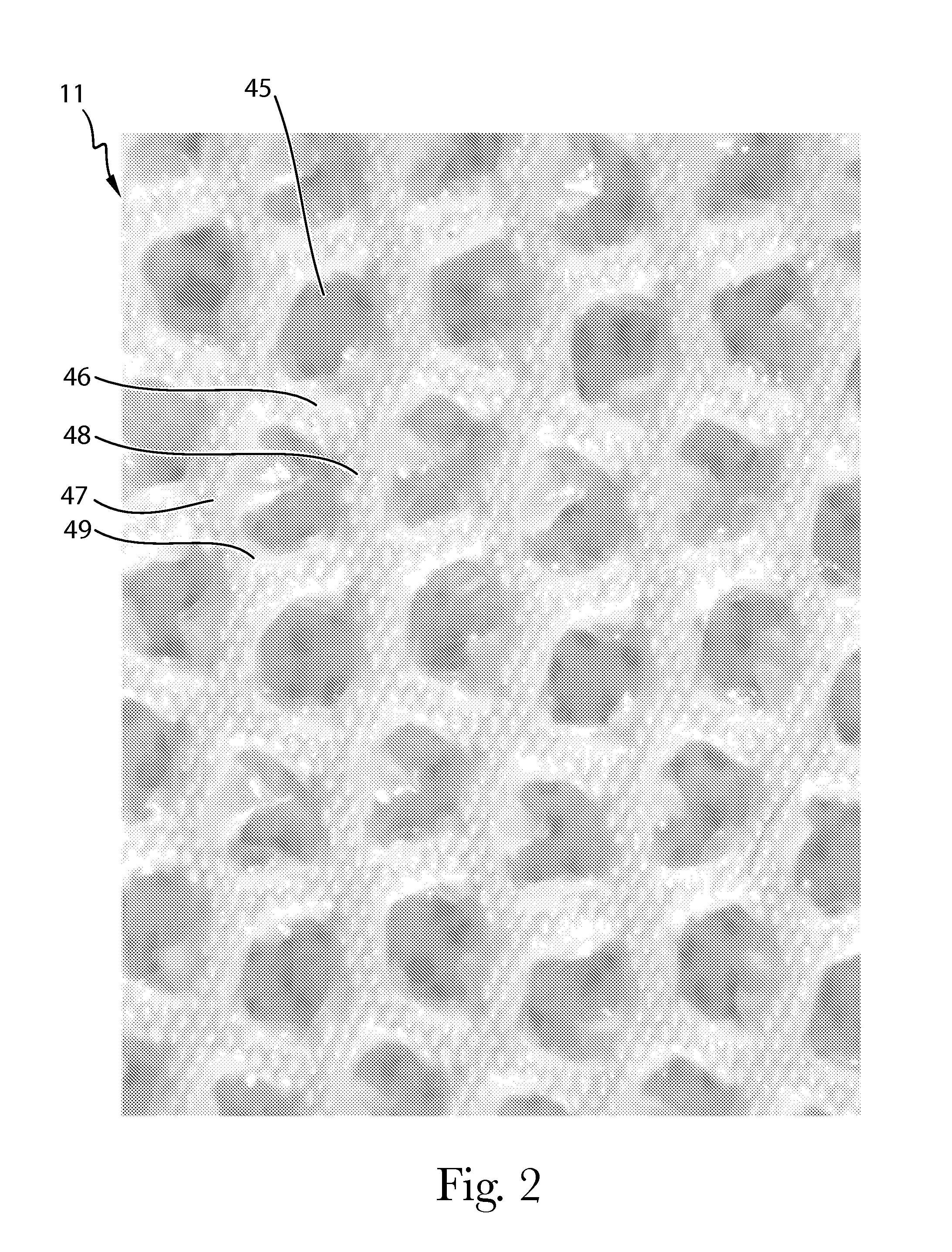

[0157]The open area and land area of formed-film topsheets was measured using light microscopy and image analysis.

[0158]Samples 1, 2, and 10 of Example 1 were analyzed. A portion of topsheet from the feminine pad having an area of 2 to 5 cm2 was removed without damaging or deforming the structure. Areas of the topsheet with thermal bond sites were avoided. The topsheet sample was placed flat with the body-facing surface upward on the glass stage of a stereo zoom light microscope (Nikon SMZ-U). The microscope was fitted with a camera for digital image acquisition of a 5 megapixel or greater (2560×1920 pixels) image, and the microscope magnification was adjusted so that the field of view to the camera was approximately 7 mm by 10 mm as shown in FIG. 47.

[0159]For measurements of open area, the topsheet was backlit so that the apertures were bright and all the rest of the topsheet area is dark. The image was focused and the lighting was adjusted to maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com