A 3D visual texture and its processing method on glass surface

A glass surface and processing method technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of three-dimensional three-dimensional effect, unable to display two-dimensional glass plane, etc., to improve the appearance competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

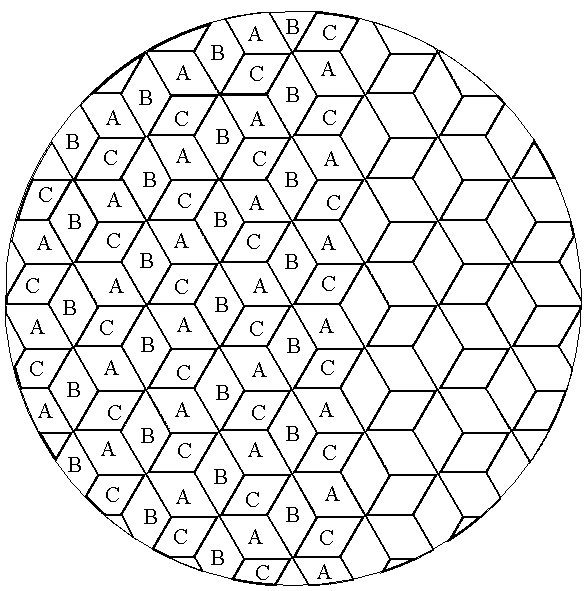

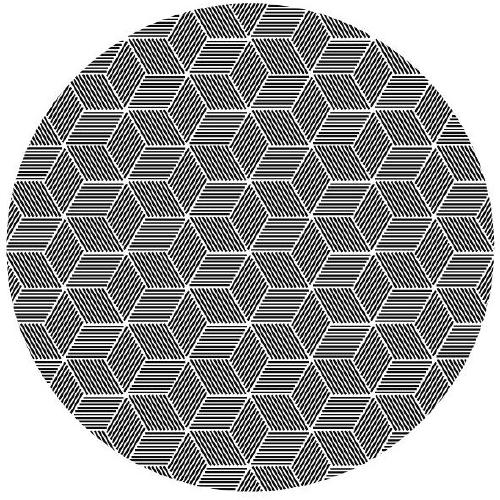

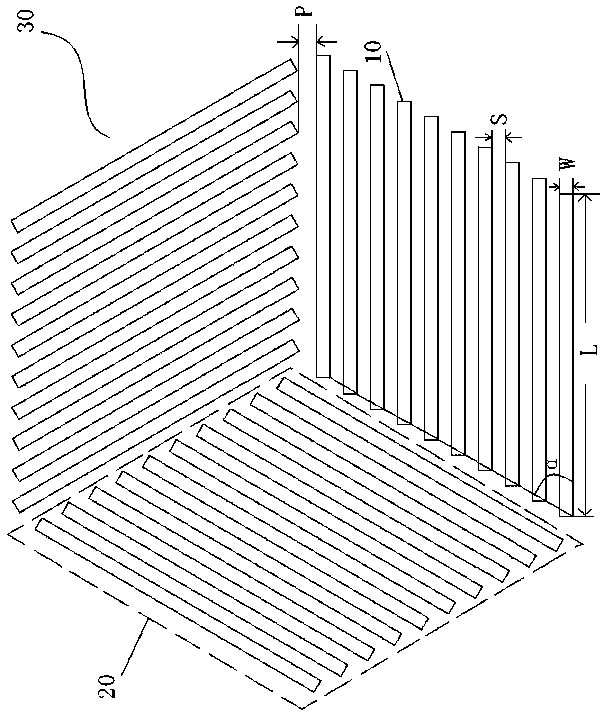

[0051] Embodiment 1, with 3D visual texture such as figure 2 and image 3 The structure shown is taken as an example, and the implementation steps are: embossing and bonding—optical coating—first printing and baking—second printing and baking—laser shaping—third printing and baking;

[0052] obtained products such as Figure 6 As shown, the following layers are included in sequence: glass 1, OCA glue layer 2, PET film 3, silicon oxide 4, titanium oxide 5. 3D visual texture 6 is embossed in the PET film 3.

[0053] In summary, the present invention discloses a 3D visual texture that is UV embossed on a PET film and presents a three-dimensional 3D effect with two-dimensional graphics, and is fixed by combining optical coating, printing, and baking. On the glass surface, the mobile phone shell made of this glass can be observed from different angles to obtain 3D visual effects of interlacing and changing virtual and real. The strong three-dimensional sense gives consumers a dy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com