Resilient Shoe With Pivoting Sole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

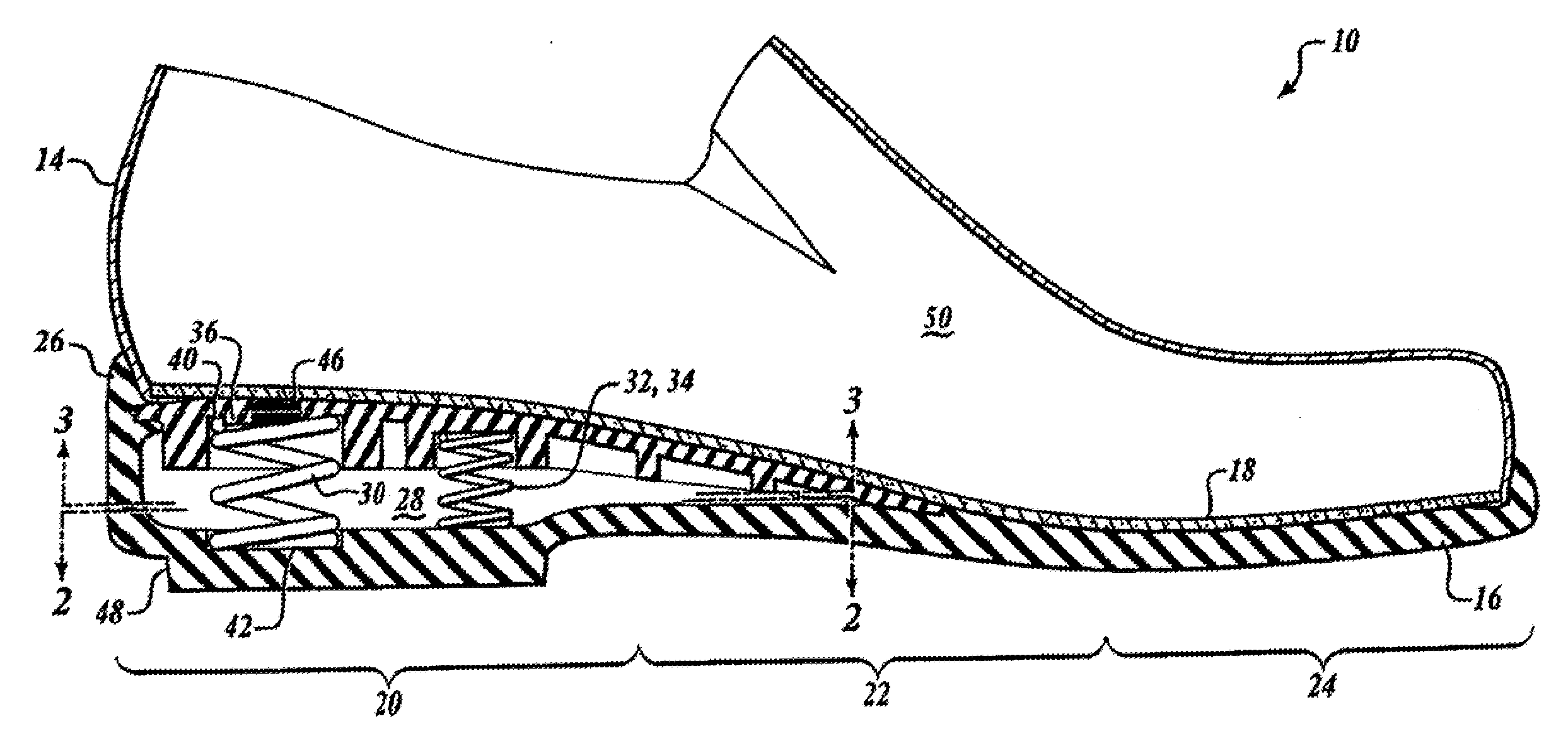

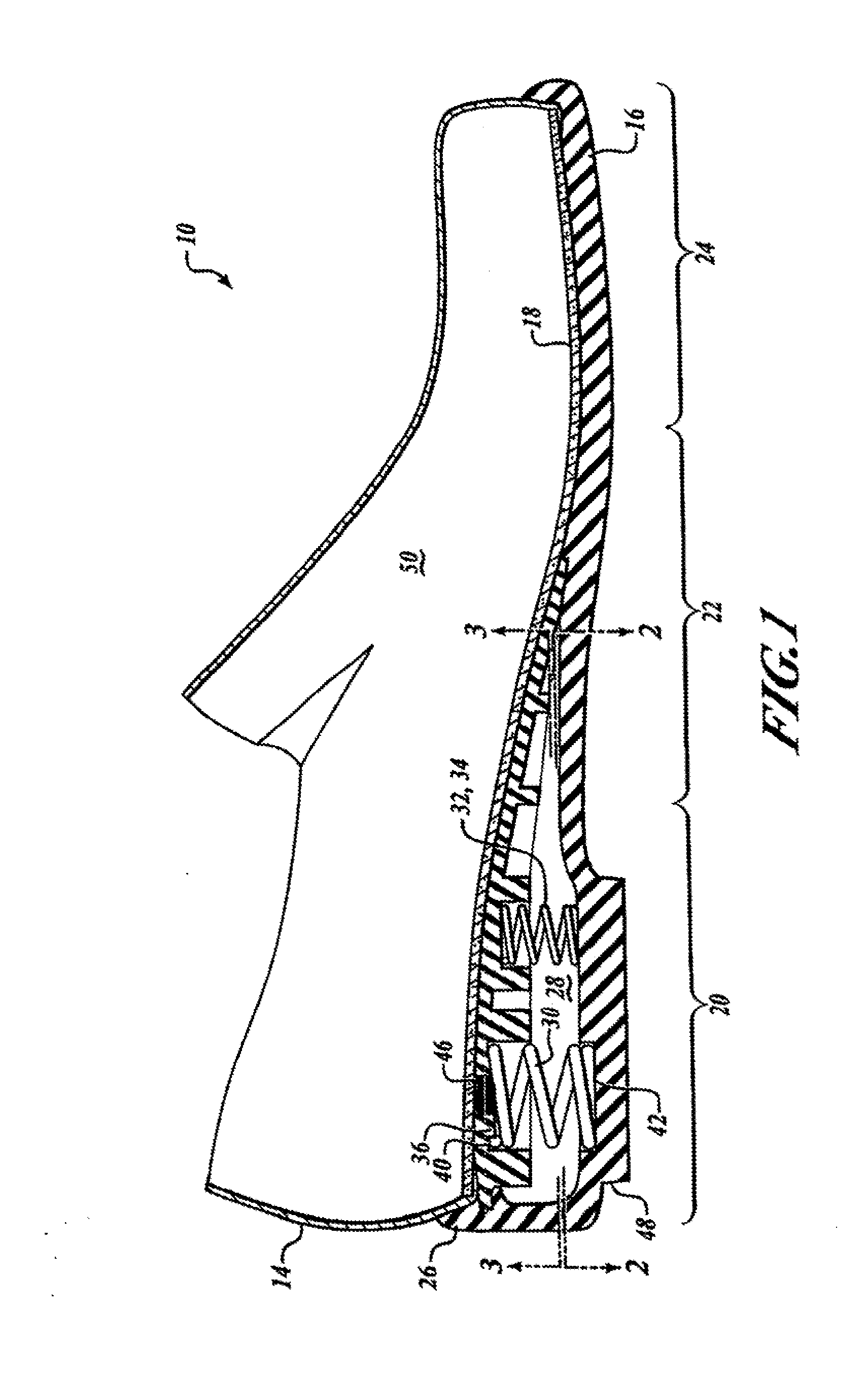

[0059]FIG. 9 illustrates a second embodiment sport shoe 200 with an upper portion 202 and sole 204, wherein the sole 204 comprises an outsole 206, and a midsole 208. Referring to FIG. 10, the outsole 206 is attached to the midsole 208, together forming a heel 209. The midsole 208 includes a first part 210 and a second part 212. The first part 210 of the midsole 208 is designed to reside substantially under the heel of a wearer, while the second part 212 supports the remainder of the wearer's foot.

[0060]Referring to FIG. 11A, a cross section of the sports shoe 200, outsole 206, midsole 208 and related structures are shown in an uncompressed state. Here, the first part 210 of the midsole 208 is disposed above and engaged by a series of springs 214. The bottoms of the springs 214 engage the outsole 206. The second part 212 of the midsole 208 engages the outsole 206. In this manner, downward pressure by a wearer's heel is distributed across the springs 214. FIG. 11A also illustrates the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com