Steam Ironing System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

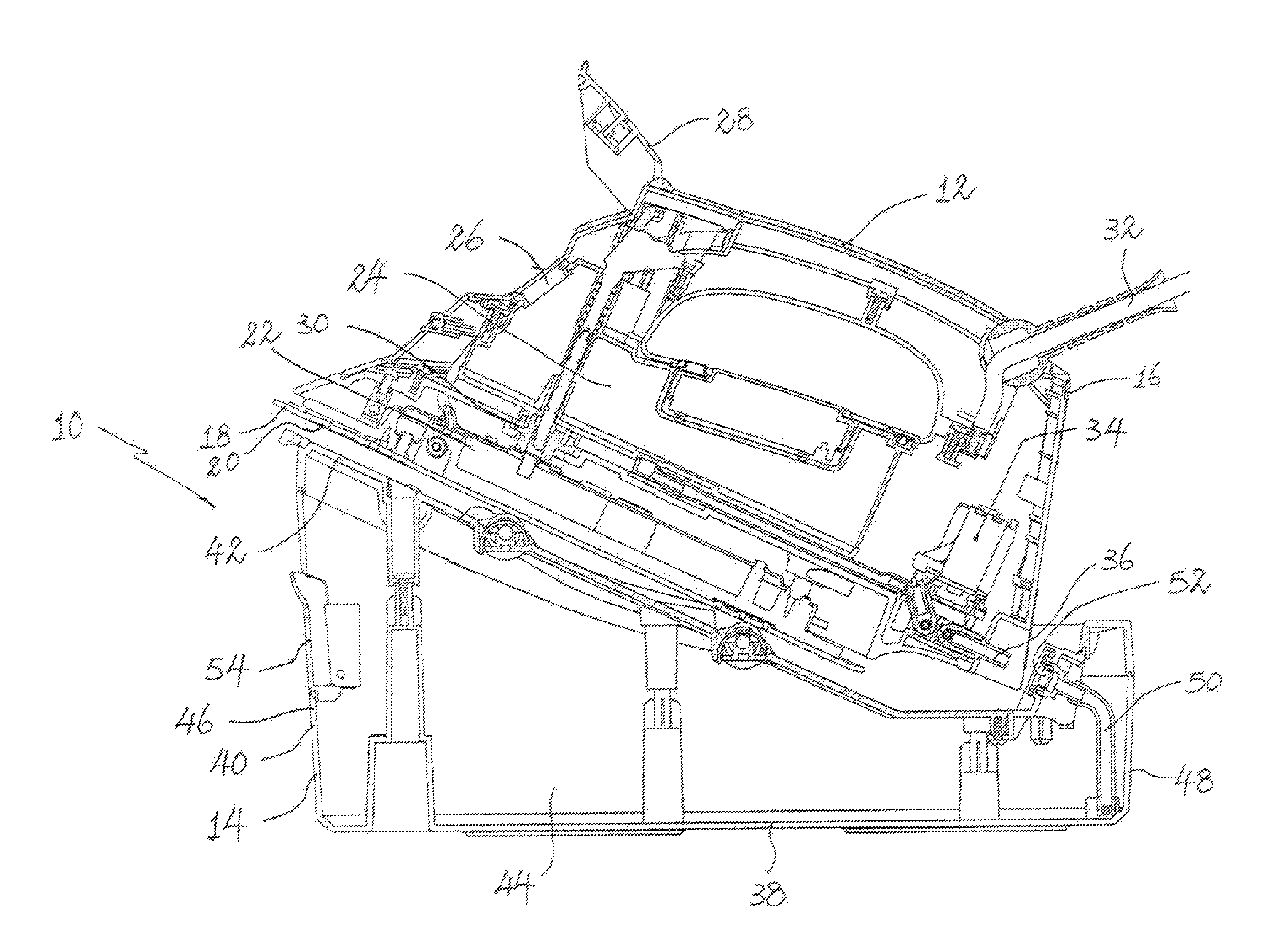

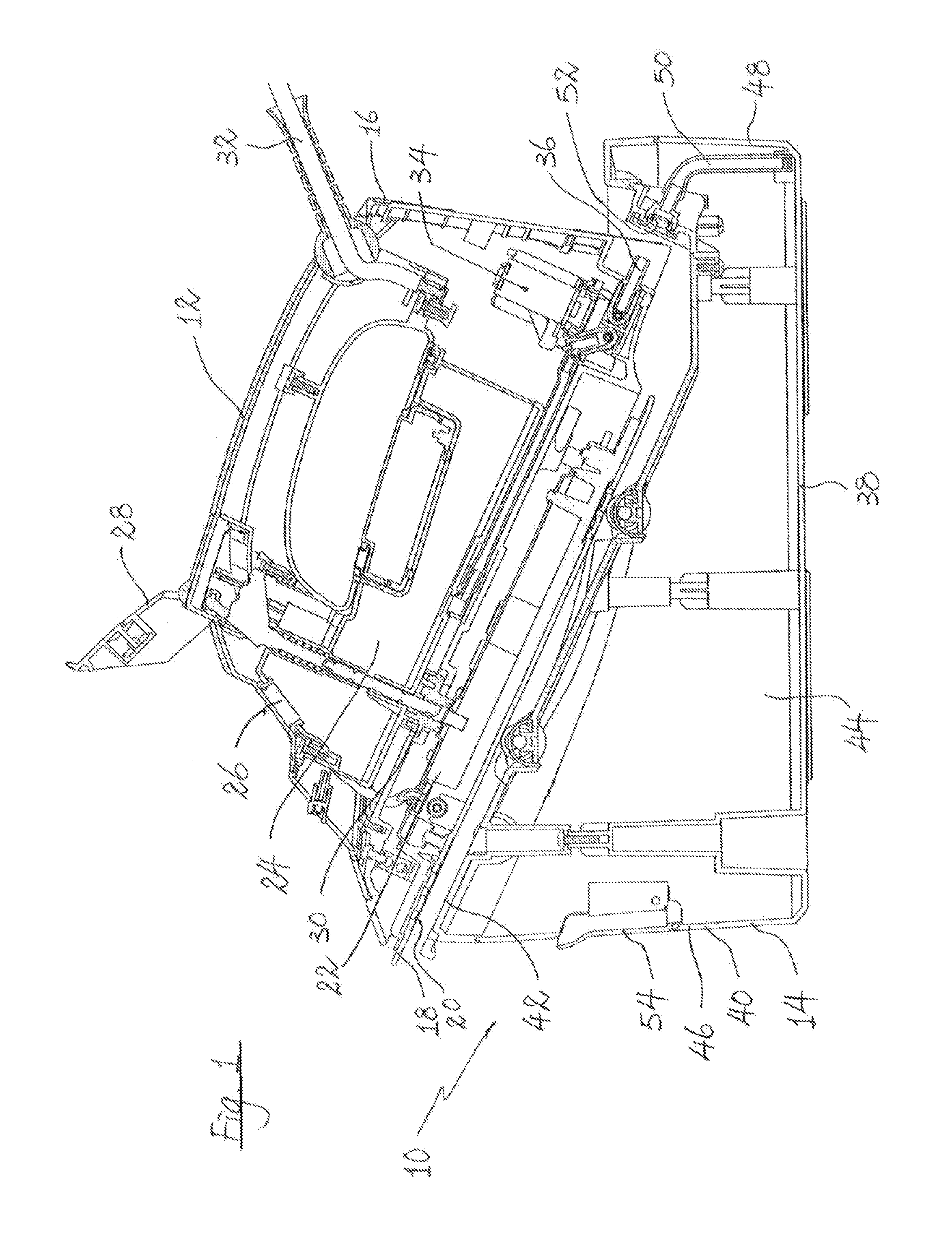

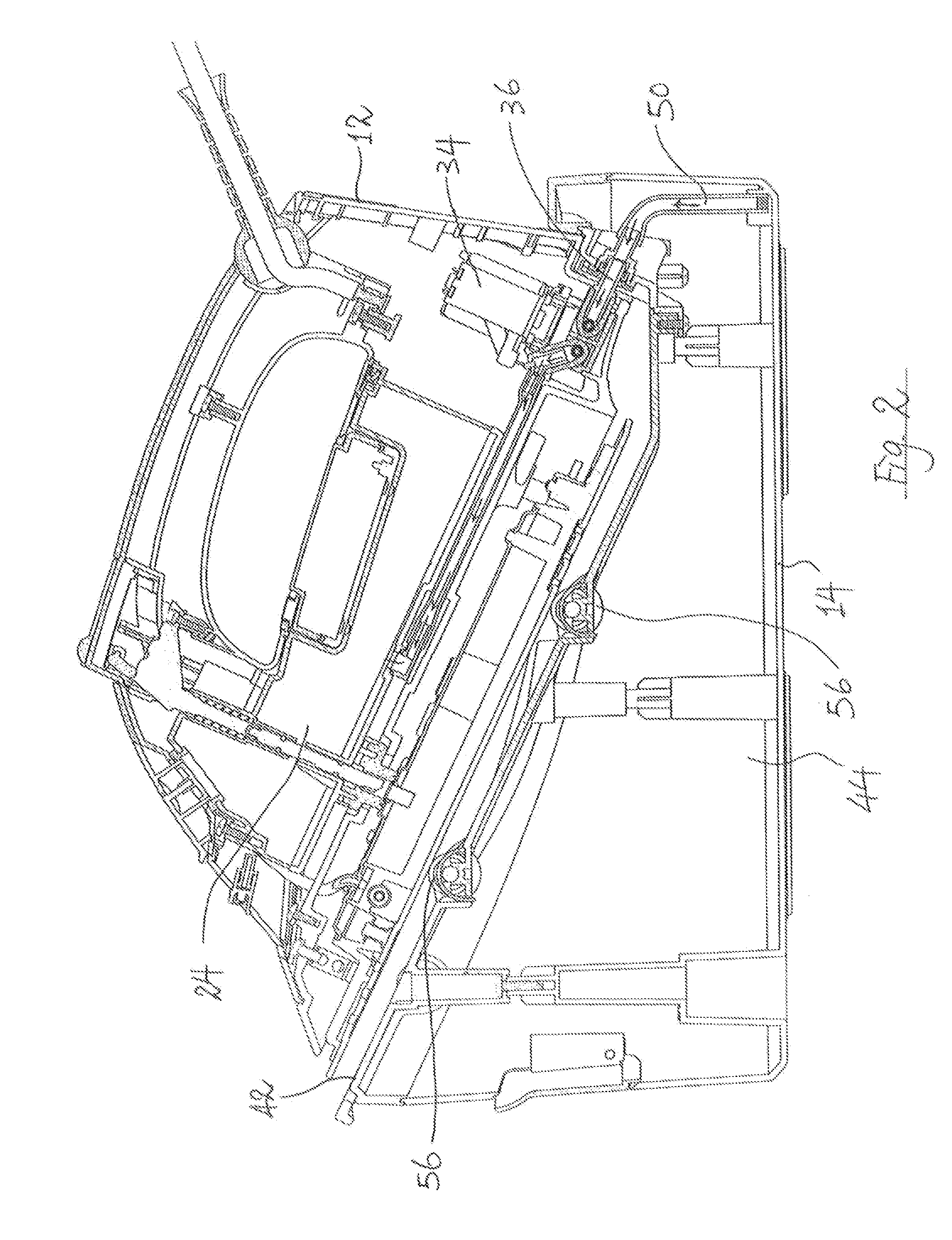

[0012]A steam ironing system according to an embodiment of the present invention is shown in FIG. 1, and generally designated as 10. The system 10 includes an electric iron 12 and a water container 14.

[0013]The iron 12 has a body 16 fixed with a soleplate 18 formed of metal or metal alloy, which may be heated to a high temperature. The soleplate 18 is formed with a number of steam outlets 20. A steam chamber 22 is formed between the soleplate 18 and the body 16. A water tank 24 is formed within the body 12 of the iron 12, and water may be introduced into the water tank 24 for storage via an opening 26 which may be closed by a lid 28 which is shown in an open position in FIG. 1. Water may pass from the water tank 24, via a closable valve 30, to the steam chamber 22. When the soleplate 18 is heated to a high temperature, water in the steam chamber 22 is converted into steam and exits the iron 12 via the steam outlets 20. Simply stated, the water tank 24, the valve 30, the steam chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com