Turbo Molecular Pump with Improved Blade Structures

a technology of molecular pump and blade structure, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of poor pumping efficiency and achieve the effect of improving the blade structure, enhancing the pumping speed and stability of the turbo molecular pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

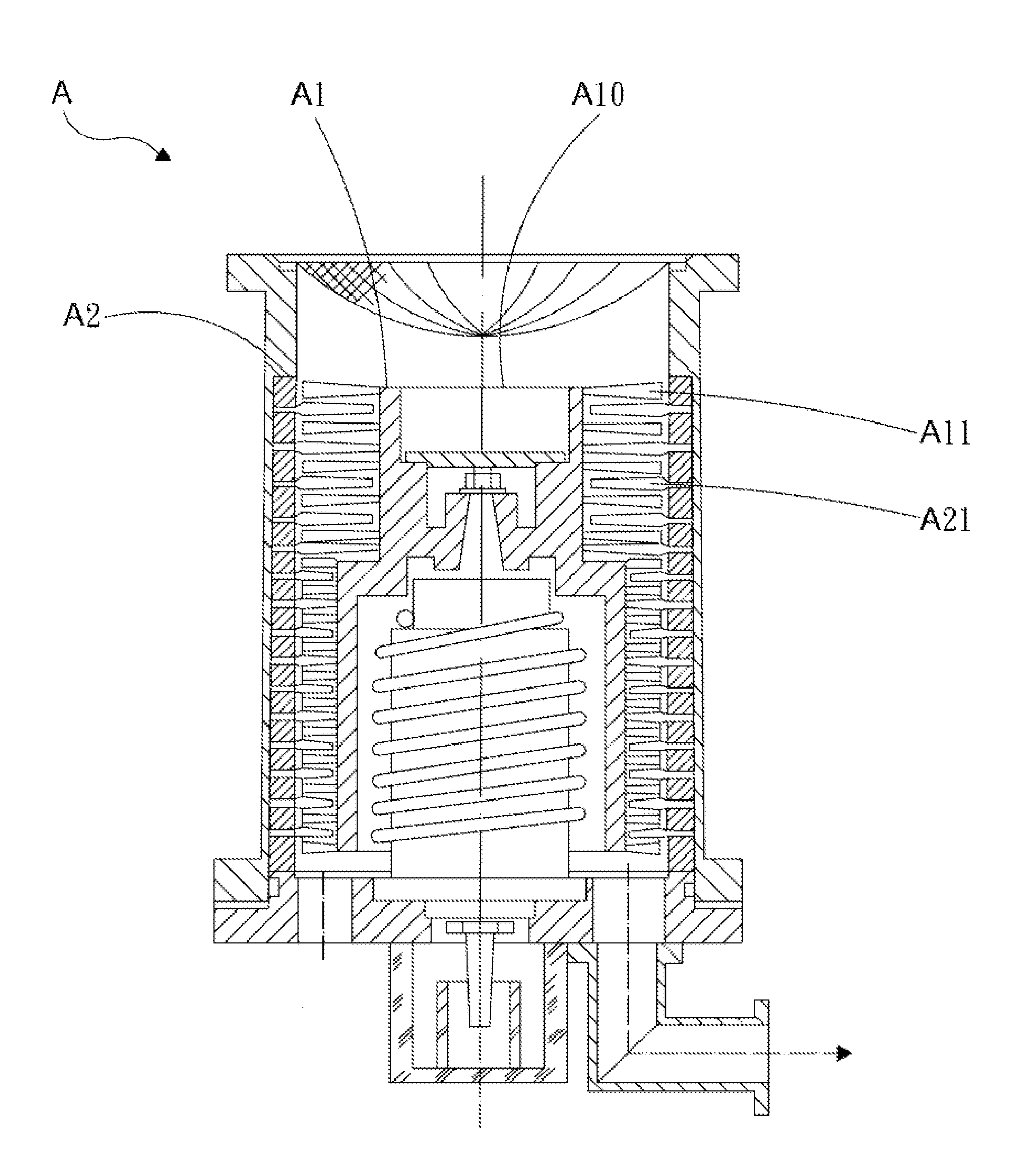

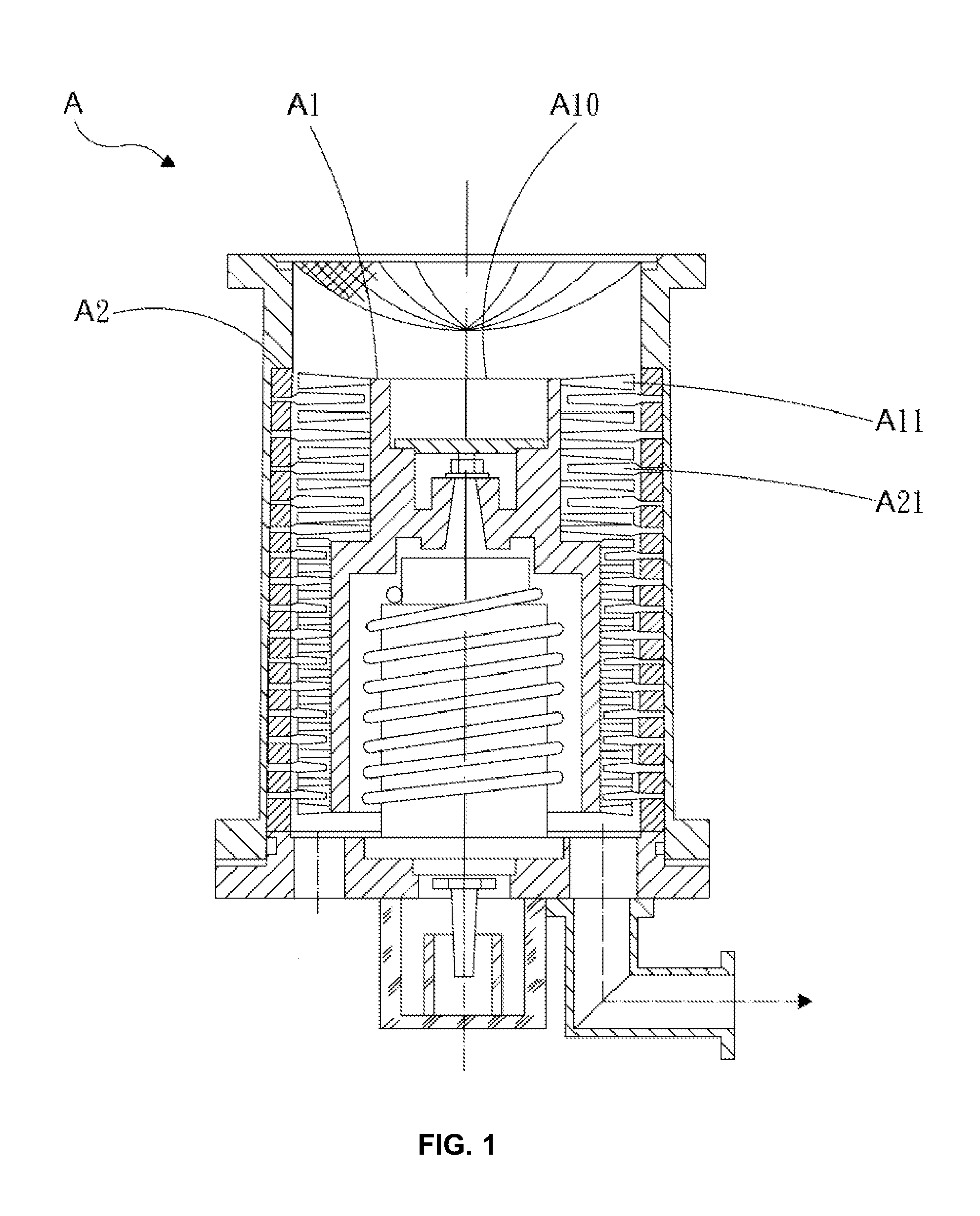

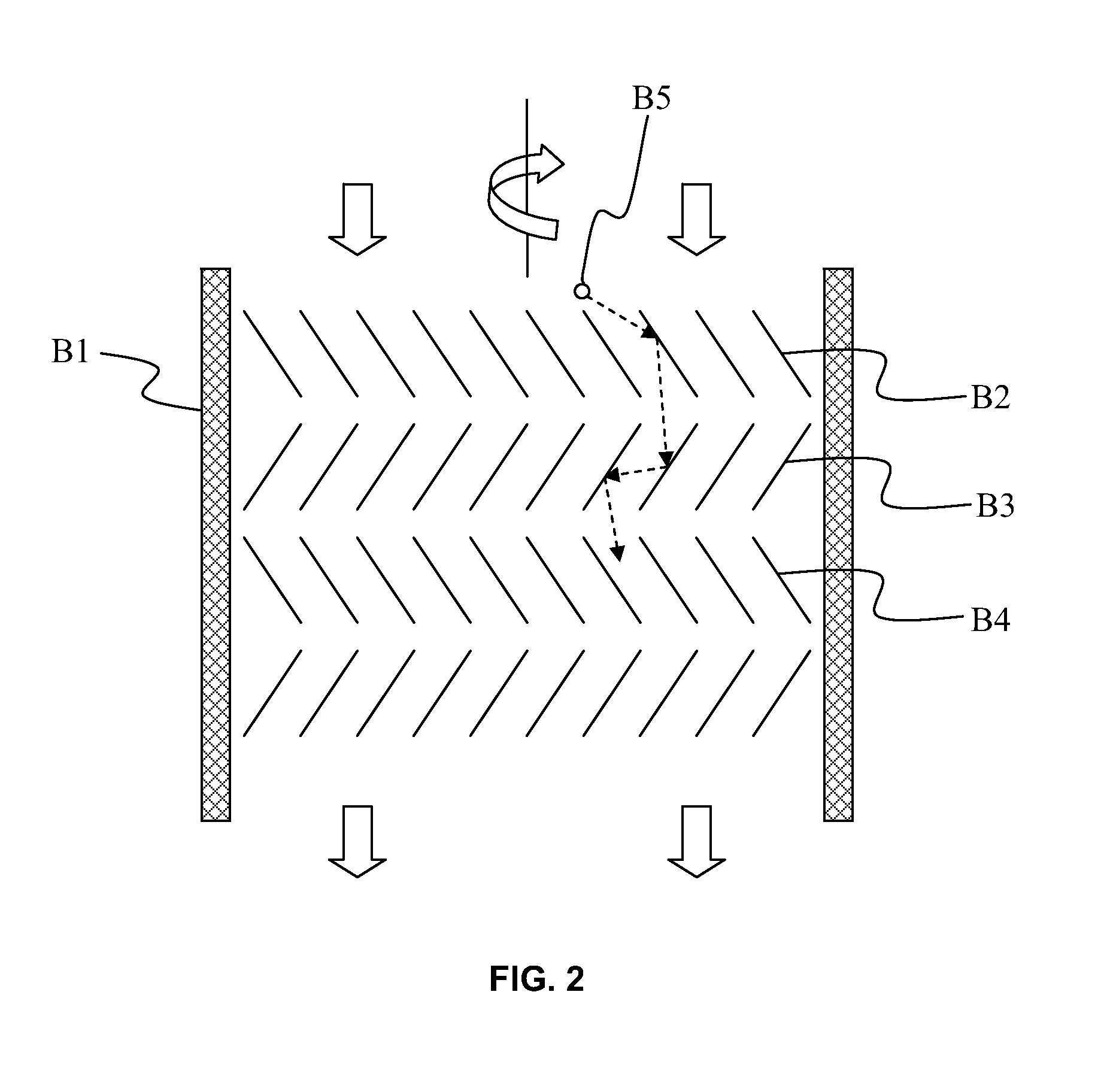

[0017]To achieve the foregoing objectives and effects, the inventors adjust several parameters of rotor blades and stator blades of a turbo molecular pump to optimal conditions, thus achieving a turbo molecular pump with improved blade structures.

[0018]The turbo molecular pump of the present invention is composed of a rotor and a stator, wherein the rotor and the stator are primarily made of pure aluminum or aluminum alloy, which has advantages of lightweight, corrosion prevention, manufacturing easily, and moderate strength and toughness. The rotor and the stator also can be made of copper or gold, however, the copper and the gold have higher cost, softer texture, higher weight, and lower strength and toughness than aluminum. Additionally, steel, iron, cast metal, and stainless steel also can be the material of the rotor and the stator, but these materials have disadvantages of rigid texture, heavy weight, susceptible to corrosion, and difficult to be manufactured.

[0019]Referring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com