Battery module

a battery module and battery technology, applied in the field of batteries, can solve the problems of secondary degradation influenced by abnormal batteries, and achieve the effect of high degree of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

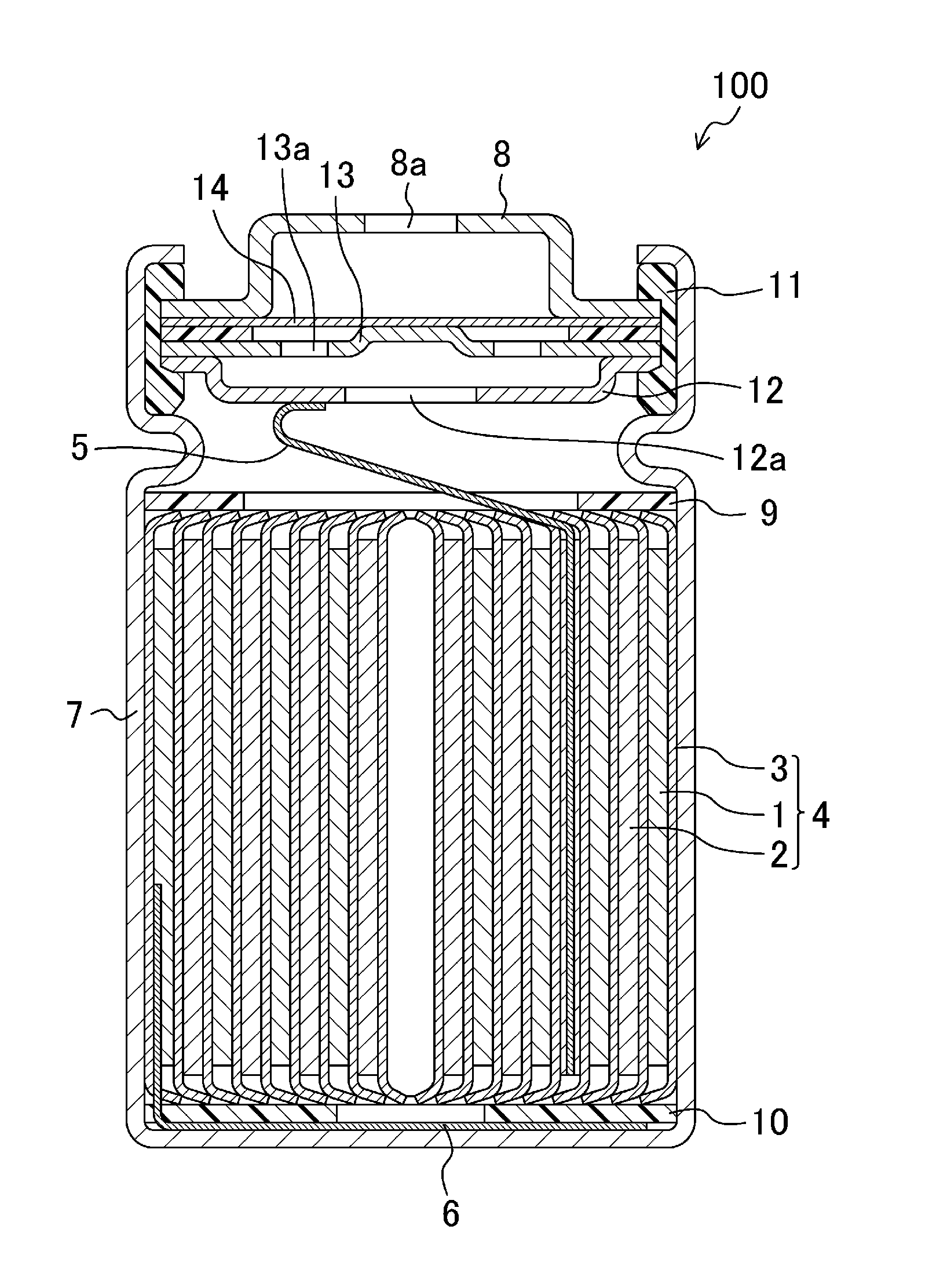

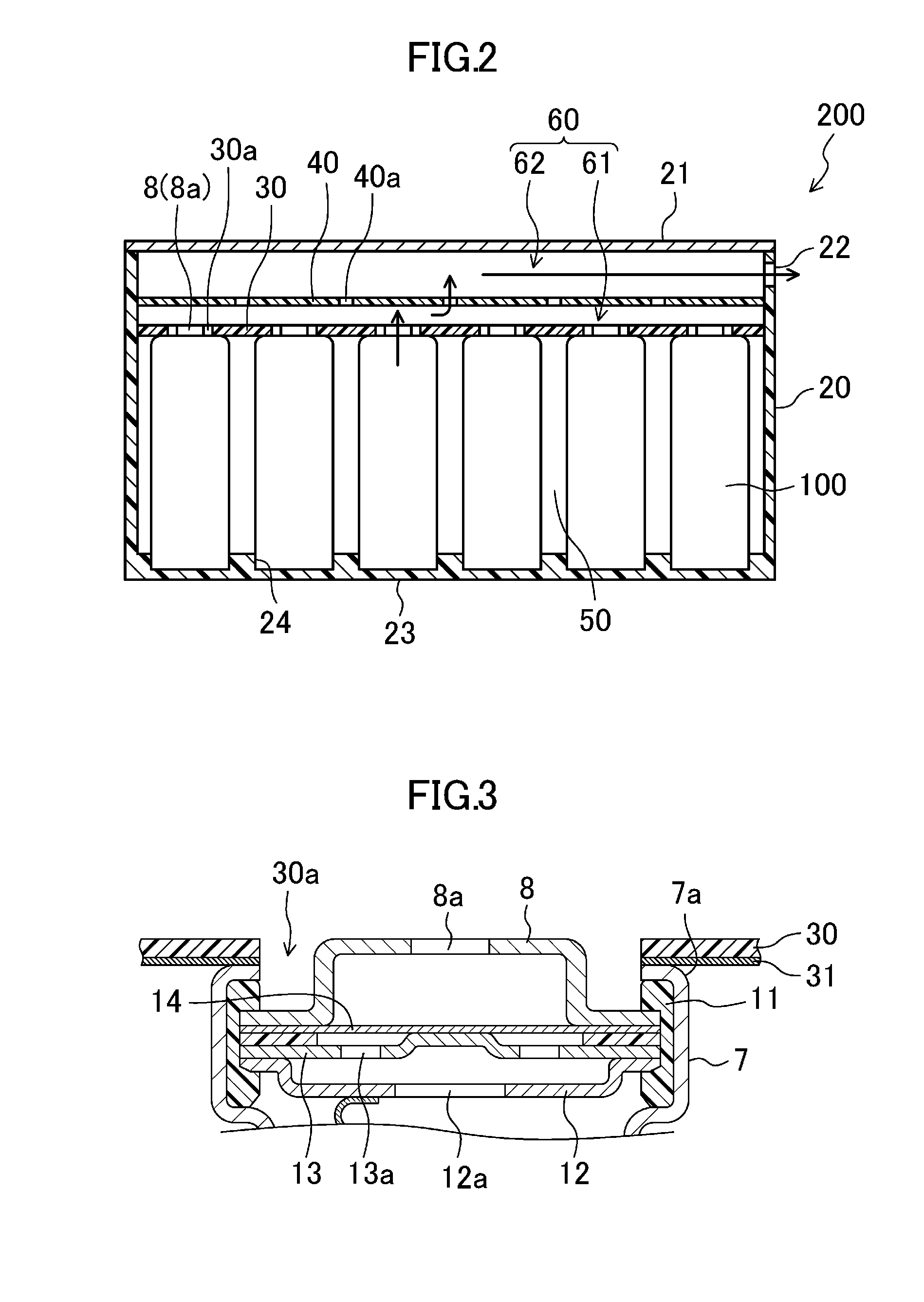

first embodiment

Variation of First Embodiment

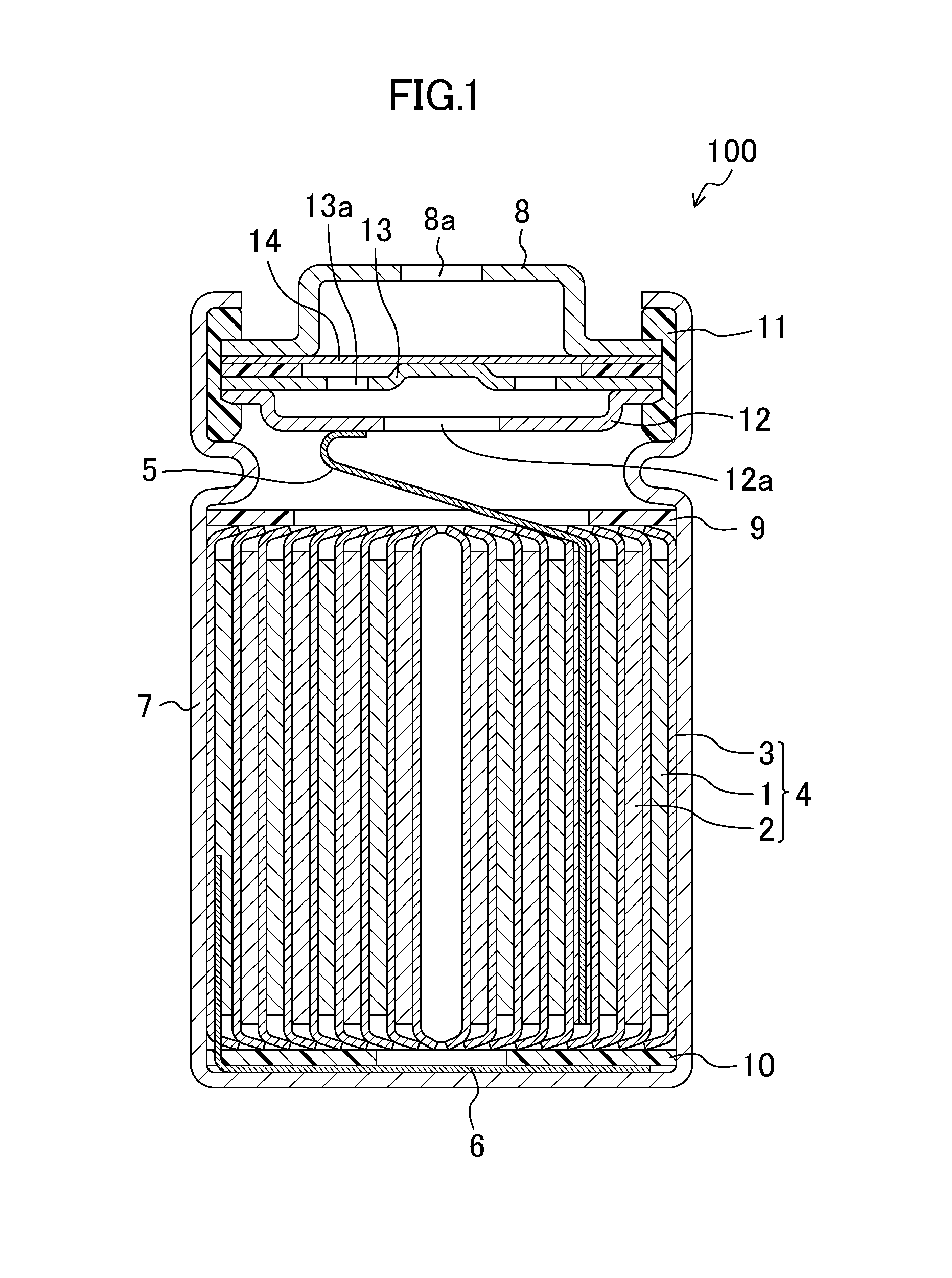

[0071]As illustrated in FIG. 2, in the first embodiment, the exhaust duct 60 is separated from the housing space 50 by a plate disposed at the same sides (i.e., toward the positive electrode terminals or the negative electrode terminals) of the cells 100. This configuration is obtained by arranging the cells 100 in the case 20 with the polarities of the cells 100 oriented in the same direction.

[0072]FIG. 6 is a cross-sectional view schematically illustrating a configuration of the battery module 200 according to a variation of the first embodiment. As illustrated in FIG. 6, this variation is different from the first embodiment in that the cells 100 are arranged with their polarities alternately oriented in opposite directions.

[0073]As illustrated in FIG. 6, the cells 100 are housed in the case 20 in such a manner that the positions of the positive electrode terminals 8 alternate between the top and the bottom, specifically, the positive electrode termina...

second embodiment

[0080]In the first embodiment, the housing space 50 housing the cells 100 and the exhaust duct 60 for releasing a gas from the vents 8a of the cells 100 are separated from each other by the flat plate 30. The flat plate 30 may have a function of electrically connecting the electrodes of the cells 100.

[0081]In this embodiment, this function of the flat plate 30 of electrically connecting the electrodes of the cells 100 will be described. The connection structure among the electrodes of the cells 100 described in this embodiment does not limit the release mechanism described in the first embodiment. In the following description, description of the housing space 50 of the cells 100 and the exhaust duct 60 will not be repeated.

[0082]FIGS. 7(a) and 7(b) are views illustrating a connection structure among the electrodes of the cells 100 connected in a line (hereinafter referred to as a “battery assembly”). Specifically, FIG. 7(a) is a disassembled perspective view, and FIG. 7(b) is an enl...

third embodiment

[0107]In the first embodiment, although the exhaust duct 60 is divided into the first space 61 and the second space 62 by the partition 40, a gas released from the first space 61 to the second space 62 has a temperature equal to or lower than a temperature at which the gas does not react with oxygen, and thus, the possibility of combustion of a gas is eliminated in the second space 62. Accordingly, unlike the first space 61, the second space 62 does not need to have a volume as small as possible for adiabatic expansion, and is allowed to have a relatively large volume as compared to the first space. In other words, an exhaust space corresponding to the second space 62 does not need to be provided in the case 20 housing a plurality of cells 100.

[0108]A battery module according to this embodiment employs a configuration in which a first exhaust space (corresponding to the first space 61) defined by a flat plate 30 placed at the same sides of the cells 100 is provided in a case 20 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com