Collection Bag for Power Equipment

a technology for power equipment and bags, applied in the field of collection bags for power equipment, can solve the problems of increasing the size of containers, insufficient clippings in bins, and the majority of current equipment, and achieve the effect of reducing the wear rate of bags during us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

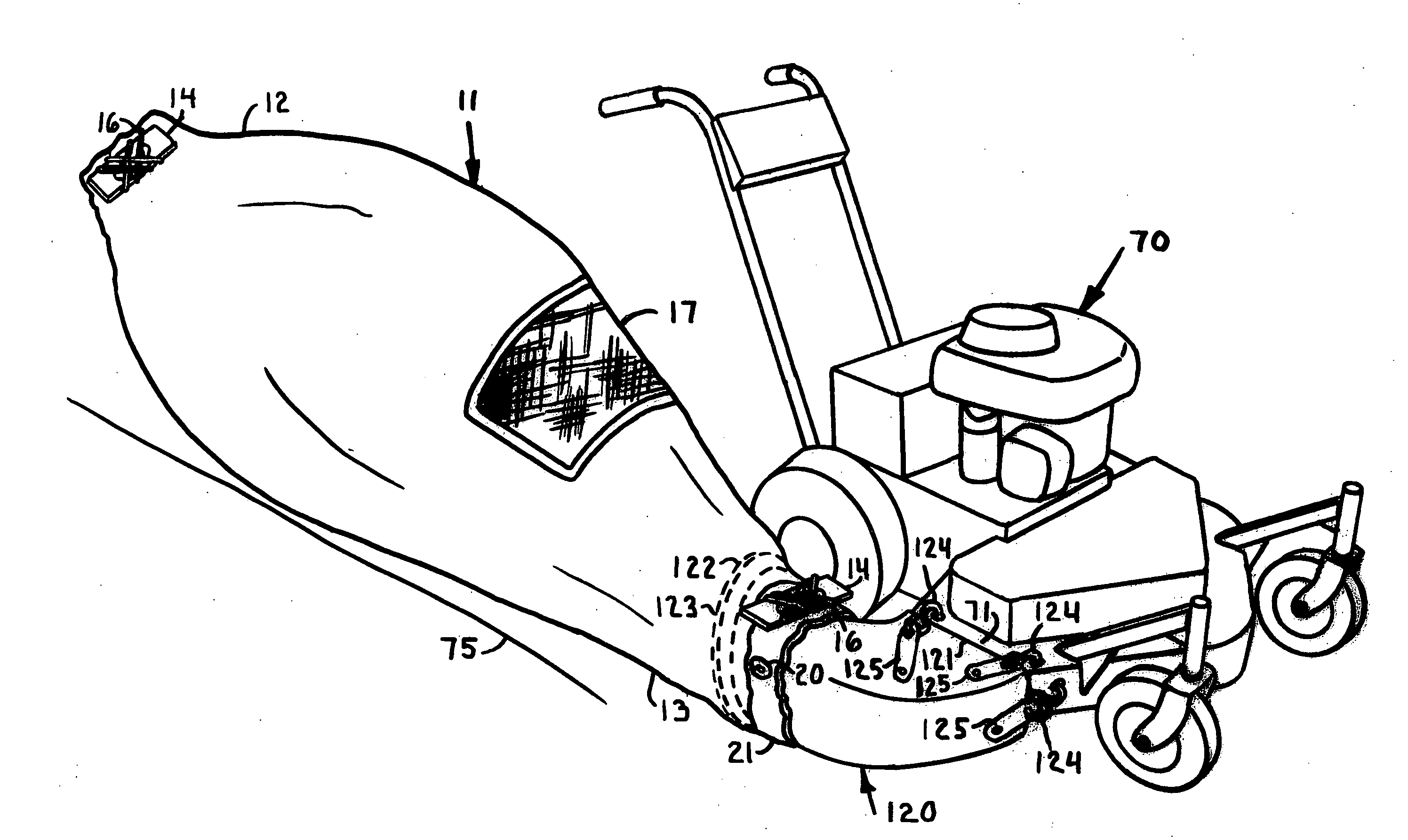

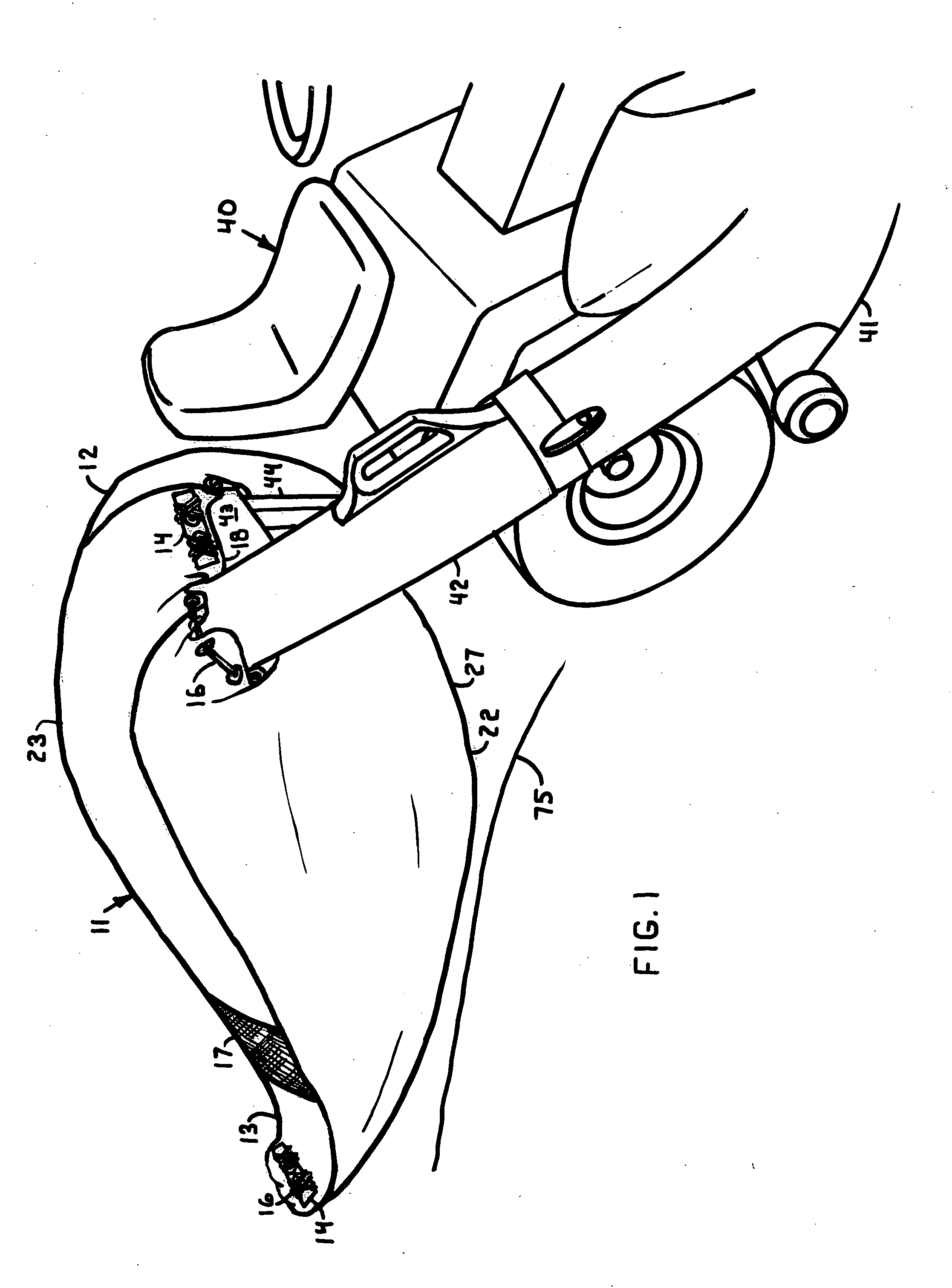

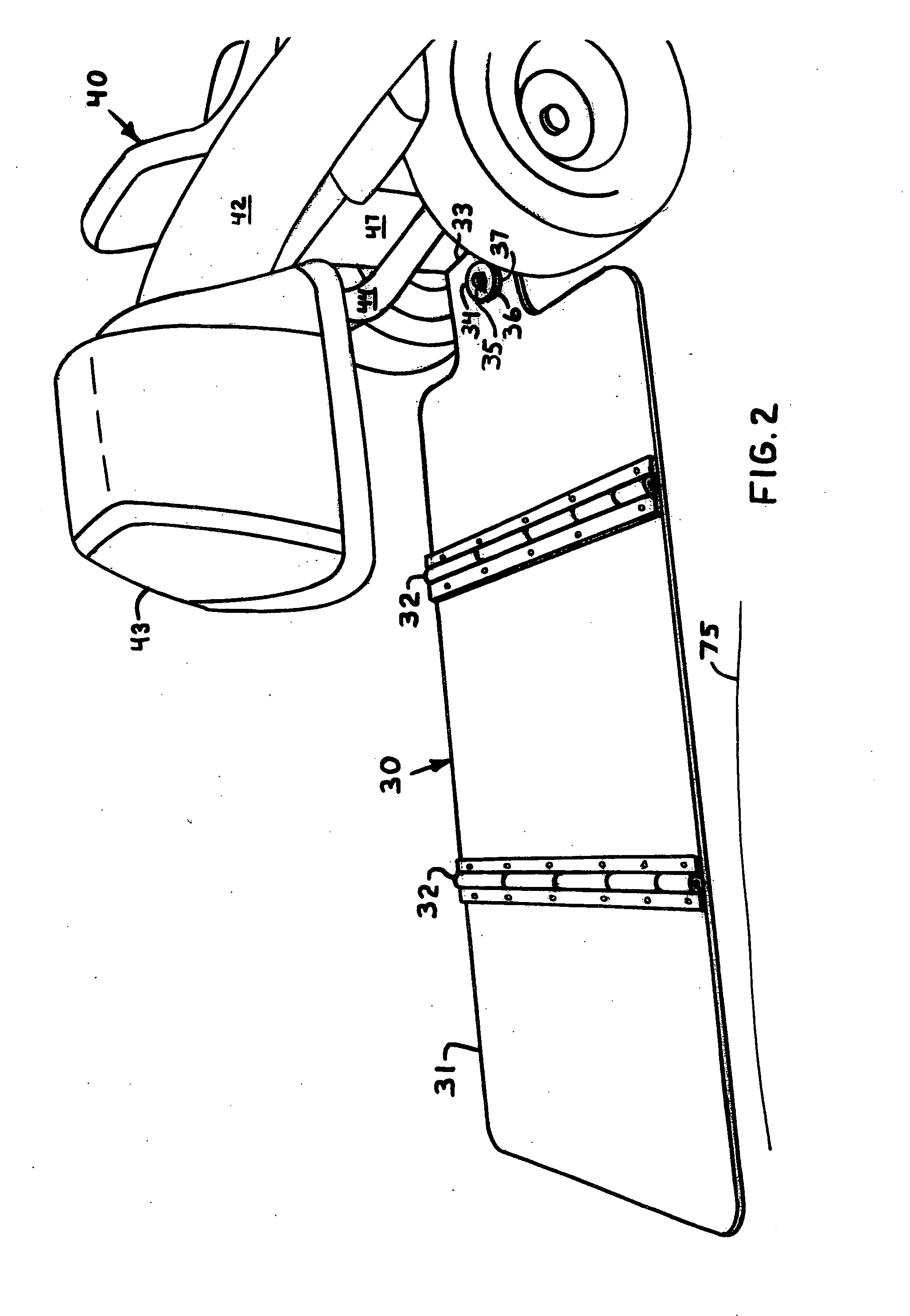

[0038]One of the improvements to previously-described debris collecting bags is a means for extending the life of the bags. The means comprises an anti-wear shield to extend bag life. In one embodiment, the shield is a support connected to the mower or other equipment that can be placed between the ground and the underside of the bag. The anti-wear shield takes up most of the linear traveling resistance or drag resistance through its attachment to the equipment, thereby greatly lessening any linear traveling resistance or drag resistance to the bag. Attached to the equipment, the anti-wear shield also reduces the force exerted on the equipment where the bag is attached. The anti-wear shield also protects the bottom surface of the bag from abrasion or punctures, thereby greatly extending the usable life of the bag.

[0039]The anti-wear shield may be attached to the riding mower's tow plate, or alternately may be attached to another part of the mower, particularly for side-exhaust mower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com