Blade Gap Setting for Blade Cutter Assembly

a cutting head and blade technology, applied in the direction of mechanical means, instruments, manufacturing tools, etc., can solve the problems of poor ergonomics, health and safety, and dull blade edge sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

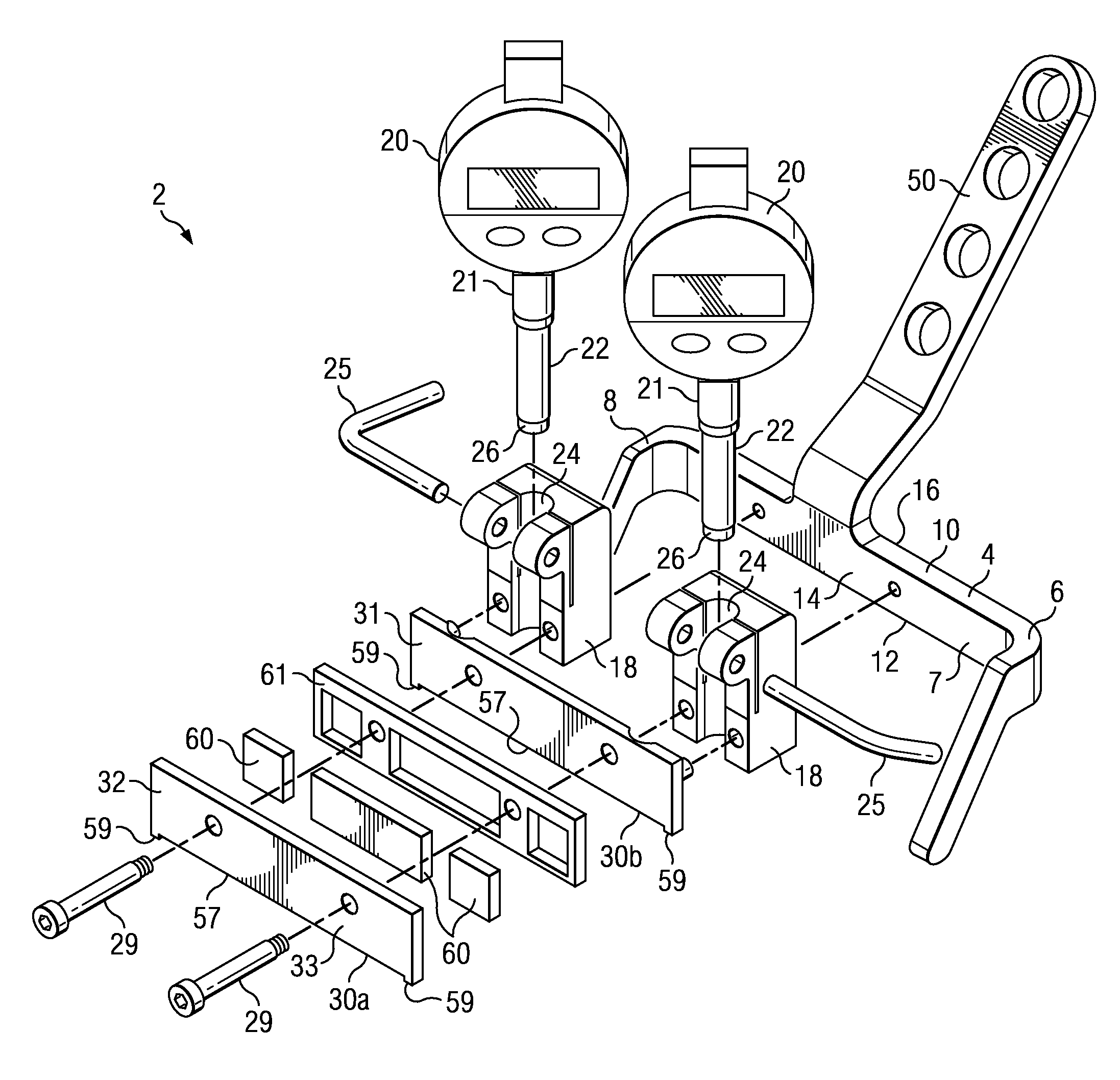

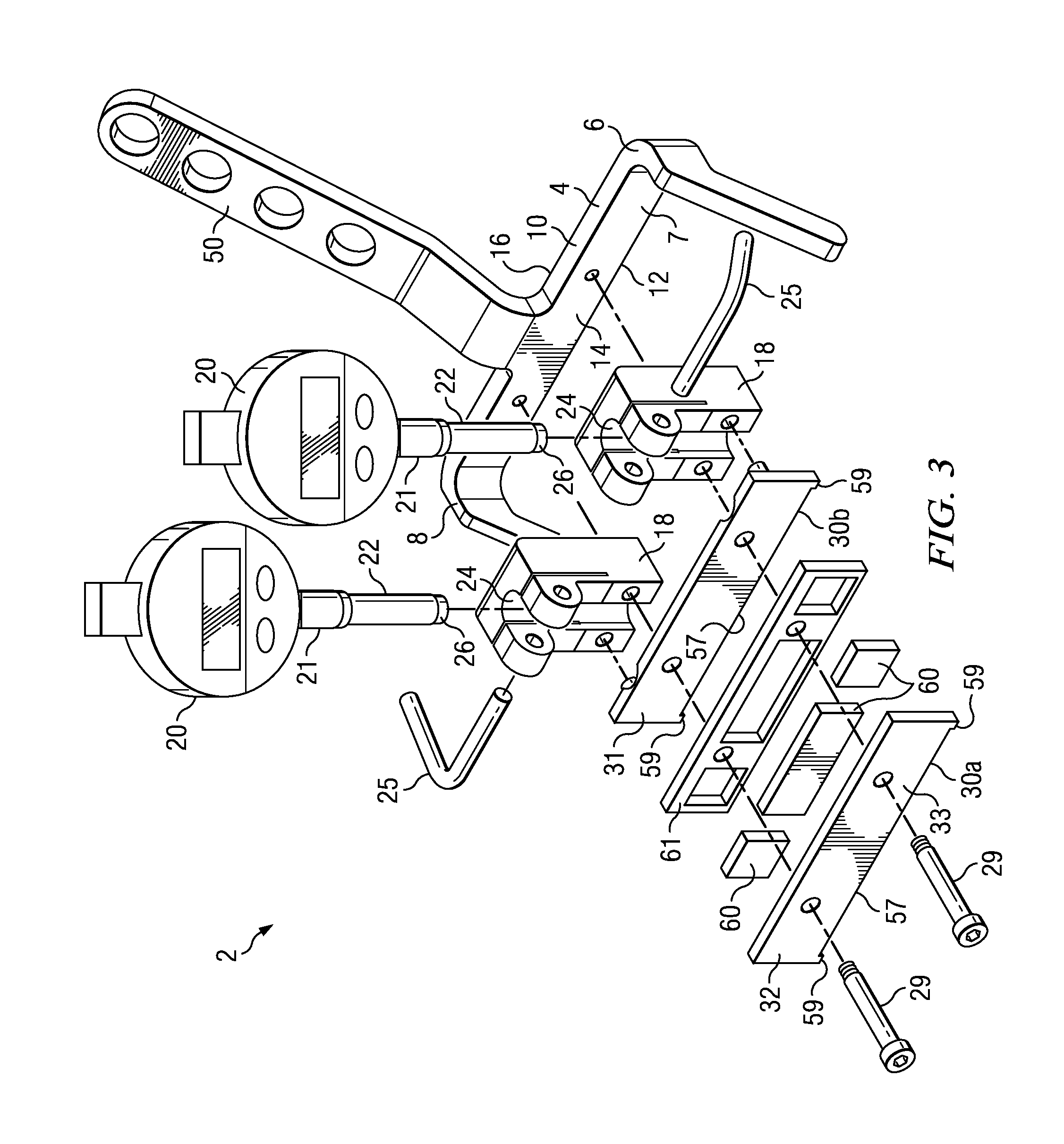

[0046]Referring to FIGS. 3 to 5, a blade gap setting device, designated generally as 2, in accordance with an embodiment of the present invention is illustrated. The device 2 includes a longitudinally extending elongate body 4 which is rigid. The body 4 is typically composed of a metal such as stainless steel. The longitudinal body 4 extends between first and second opposed ends 6, 8. The body 4 includes a support portion 7 which has an upper face 10, a lower face 12, a front side 14 and a rear side 16. Located inwardly of a respective end 6, 8 and fitted to the front side 14 are a pair of mountings 18 of the body 4, each mounting 18 adapted to mount a respective depth micrometer 20 having a displaceable spindle 22. The mounting 18 includes a hole 24, or channel as illustrated, extending downwardly there through to permit the depth micrometer 20 to be removably inserted into the hole 24. This mounts the depth micrometer 20 to the body 4 with a free end 26 of the displaceable spindle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com