Pressure Decay Leak Check Method and Apparatus

a leak check and pressure decay technology, applied in lighting and heating apparatus, fluid tightness measurement, instruments, etc., can solve problems such as harmful refrigerant to be released into the atmosphere, affecting the performance and accuracy of refrigerant recovery units, and fire in refrigerant recovery units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

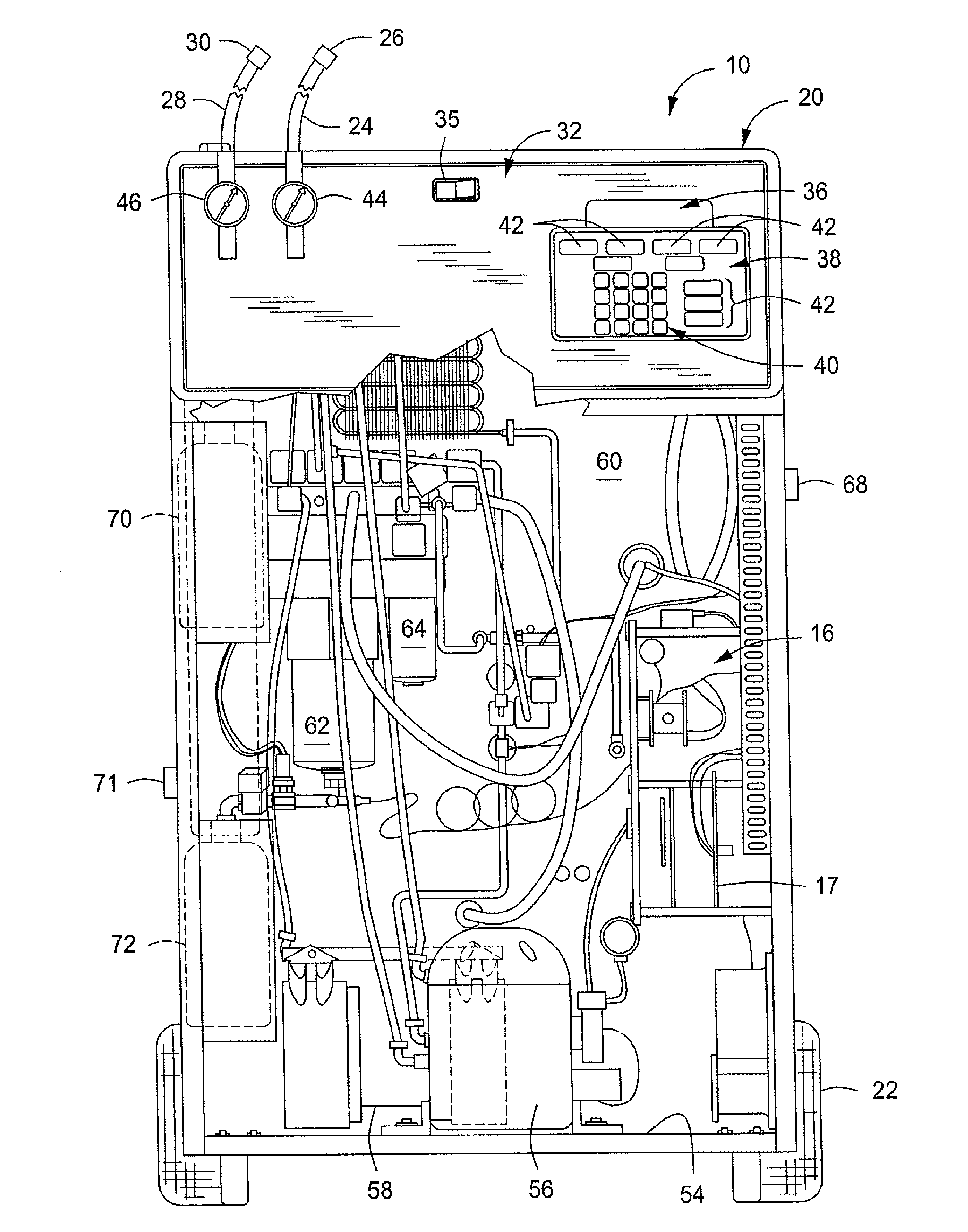

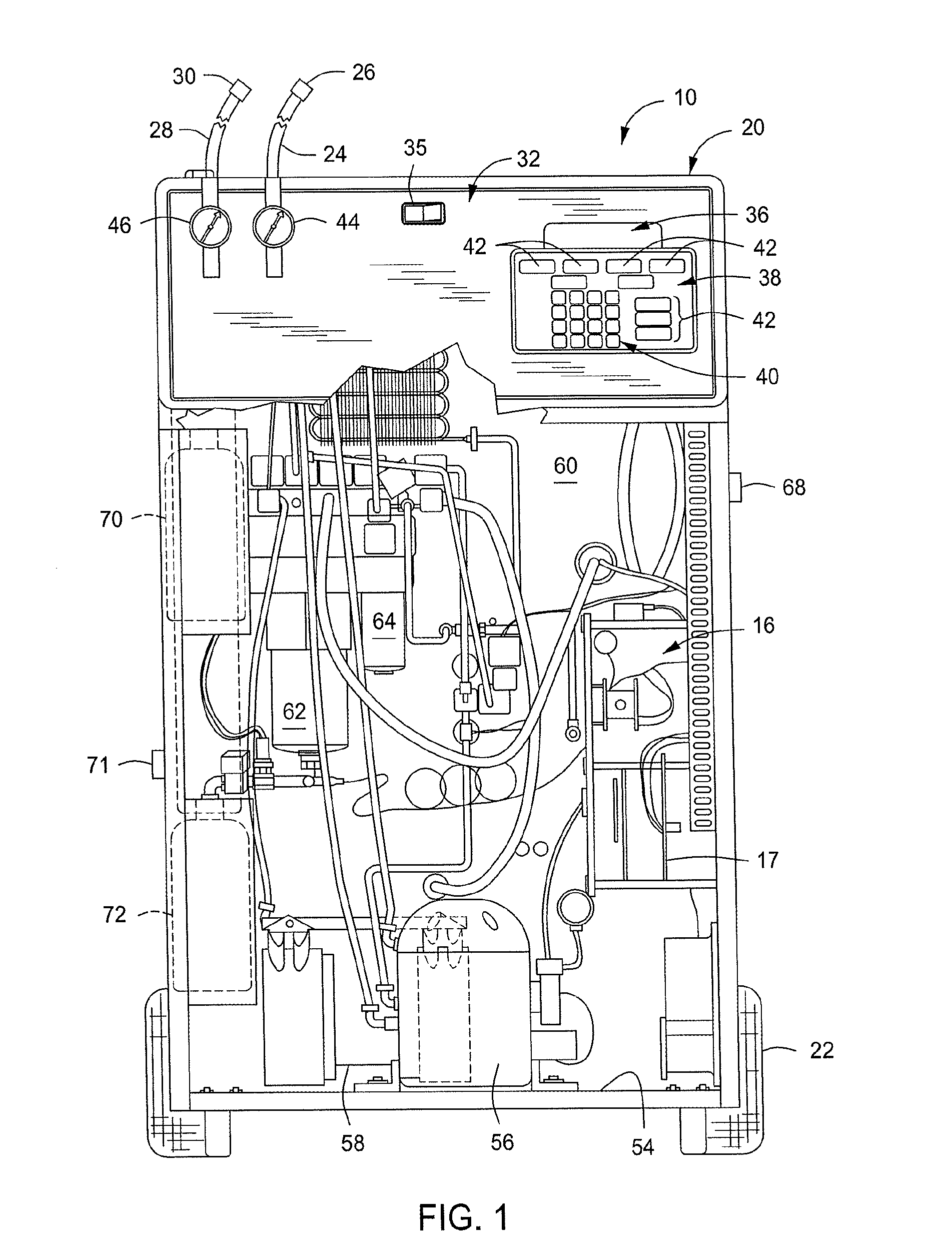

[0018]The invention will now be described with reference to the drawing figures, in which like numerals refer to like parts throughout. A refrigerant recovery unit is provided that includes the ability to self-check for refrigerant leaks in order to prevent continued venting of a refrigerant into the atmosphere.

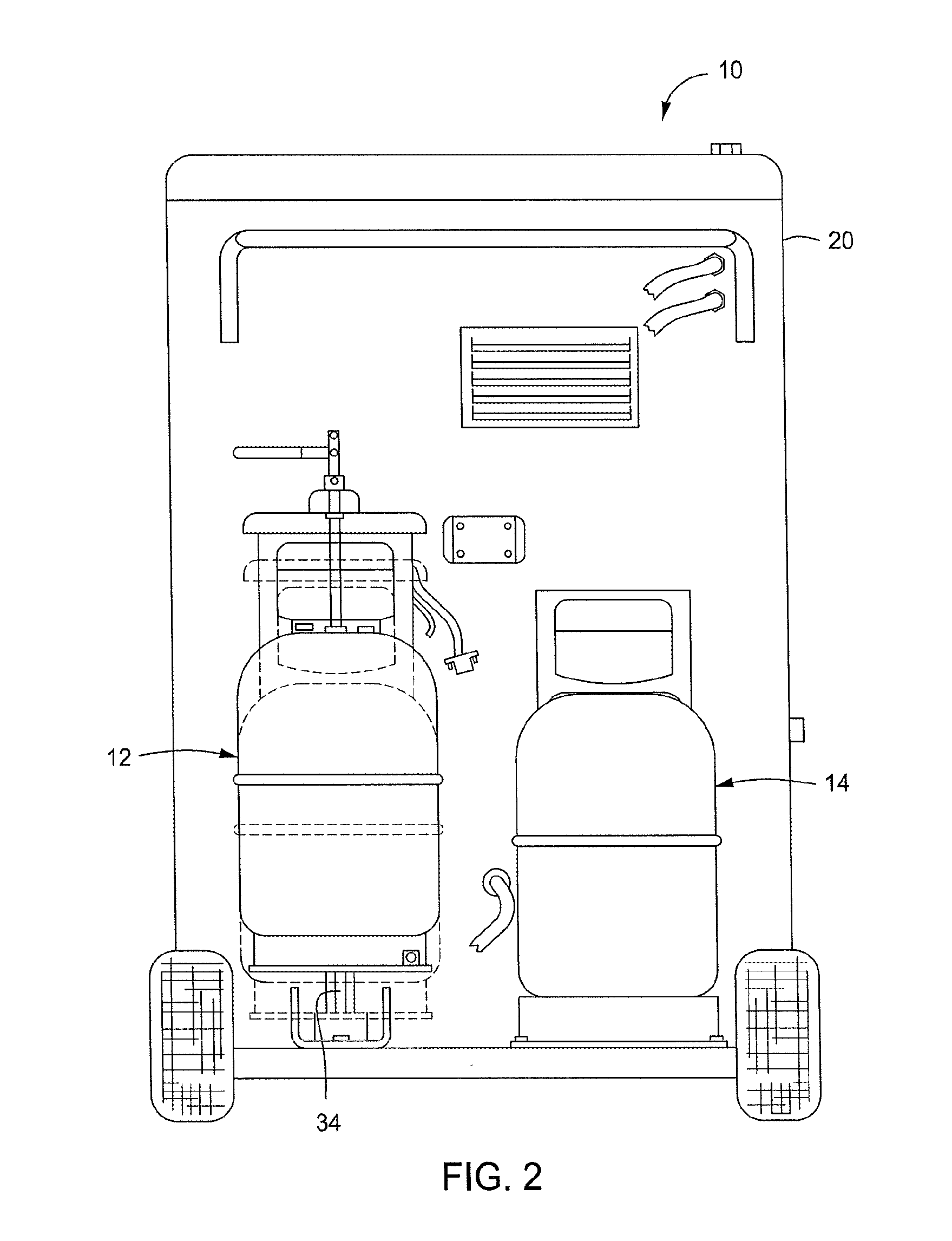

[0019]FIGS. 1 and 2 show an example of a portable refrigerant recovery unit 10 (recovery unit) constructed according to principles of the invention, for recovering, recycling, and recharging refrigerant from a refrigerant system of a vehicle. Other refrigerant systems, such as ones in a house or a building, are also within the embodiments of this invention.

[0020]The refrigerant recovery unit 10 is a machine having a cabinet 20 supported by a pair of wheels 22, for portability. The refrigerant recovery unit 10 includes a first container or main tank 12 for holding a primary supply of refrigerant, such as 1234yf. The main tank 12 may also be referred to as an internal storage v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com