Method of manufacturing molded article including component insert-molded in resin mixed with solid powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

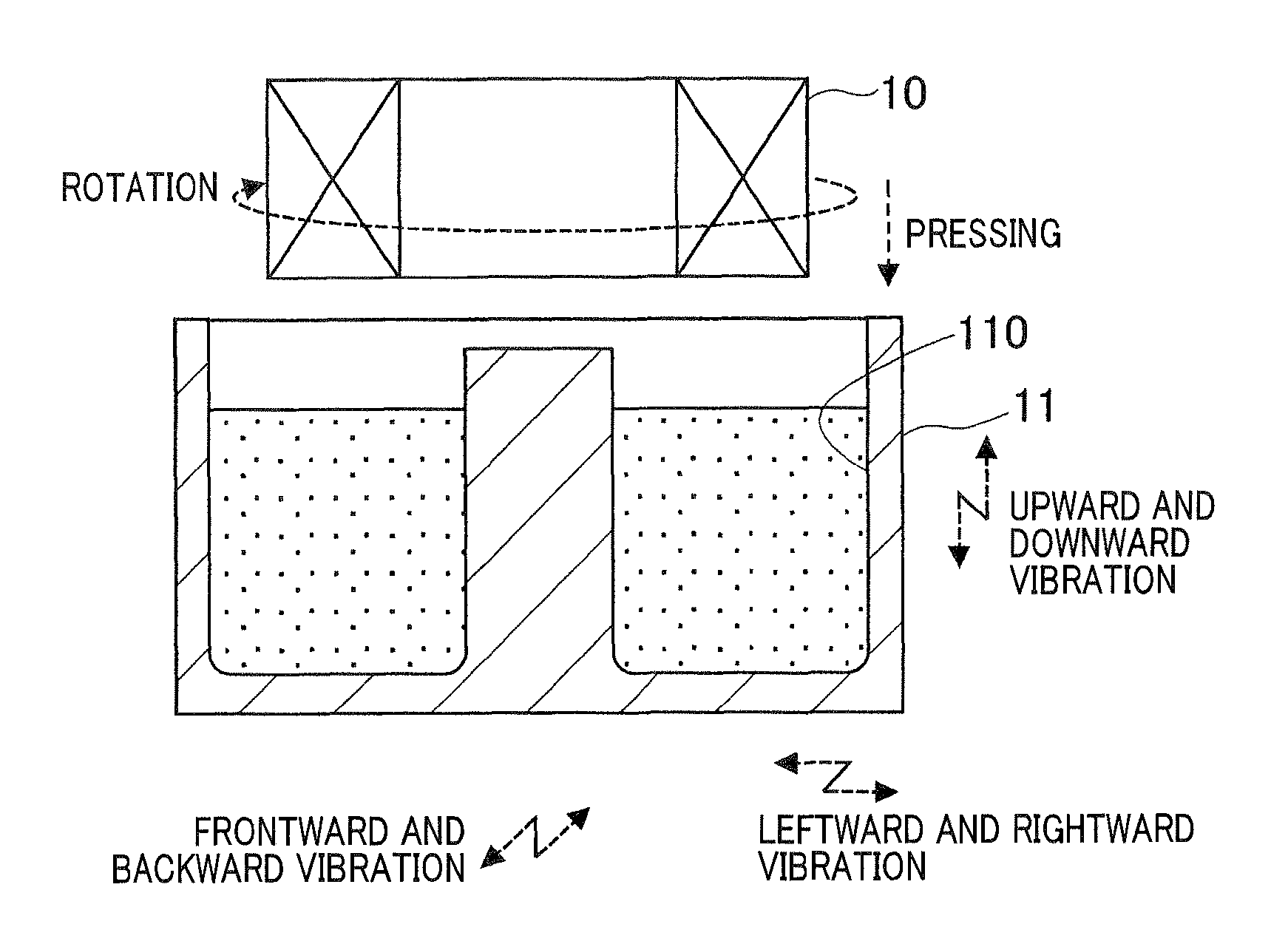

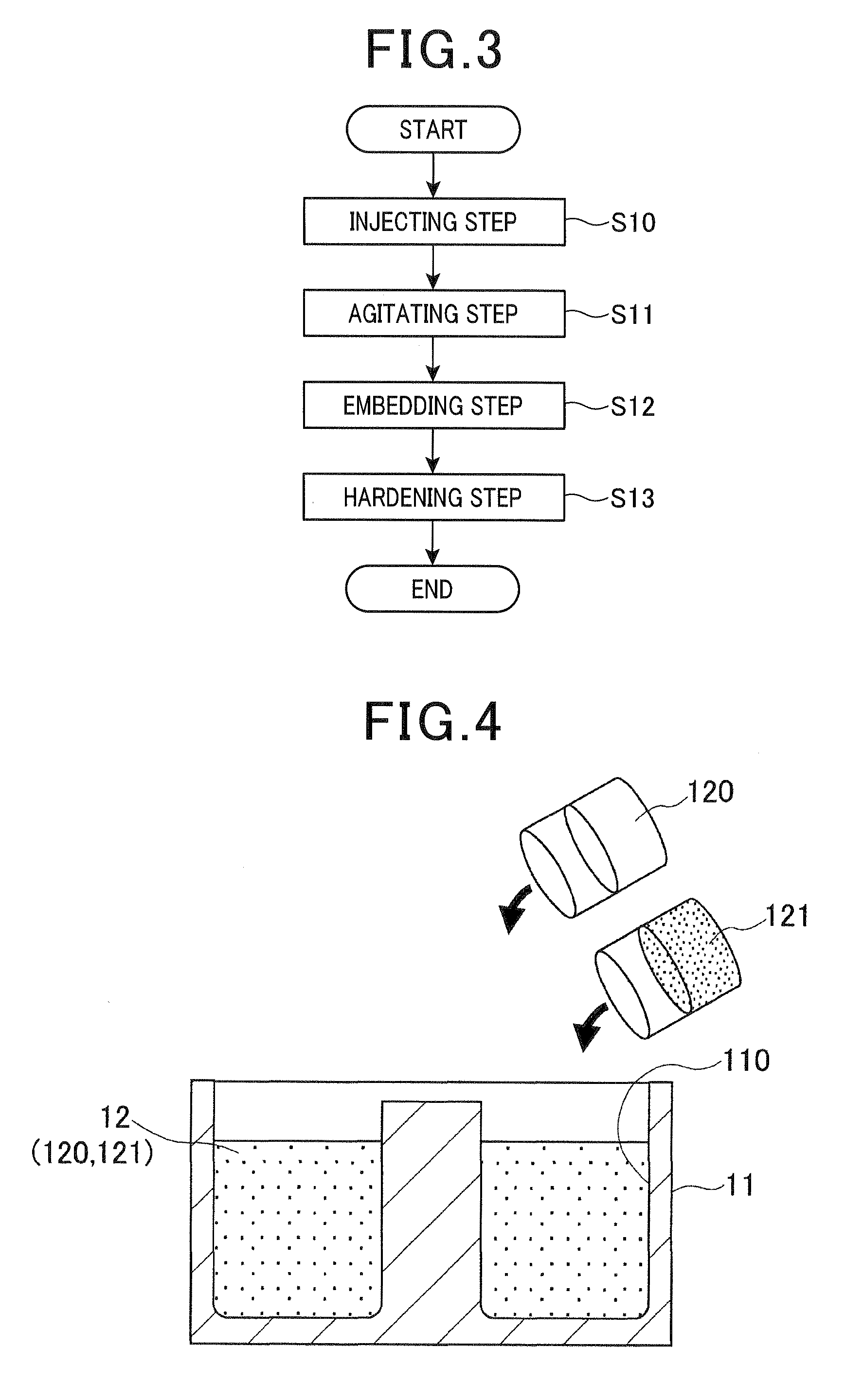

[0026]The present invention will be described by way of an embodiment for manufacturing reactors for use in a motor control apparatus which controls a vehicle-driving motor.

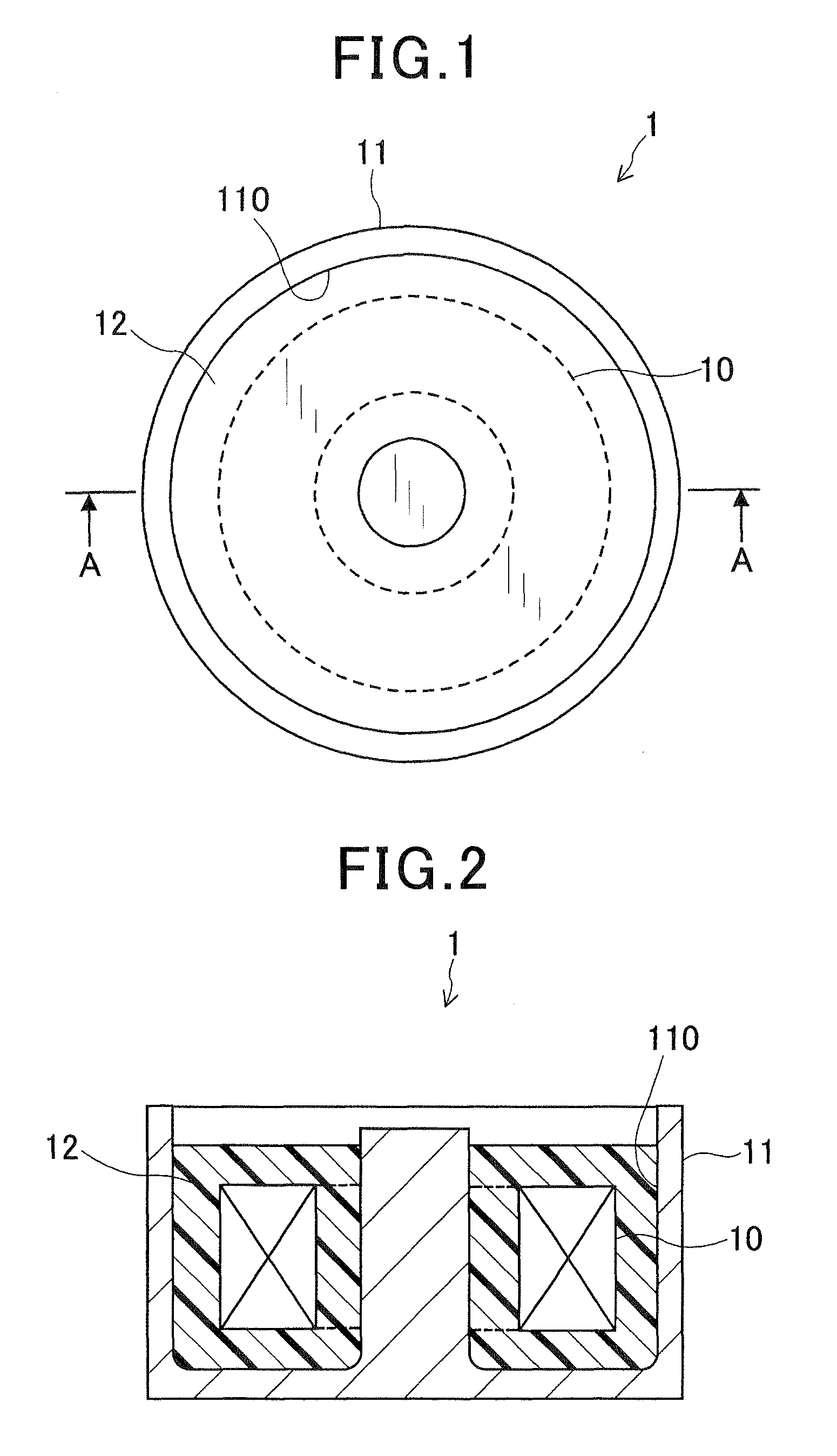

[0027]First, the structure of a reactor 1 manufactured by the method according to the embodiment of the invention is explained with reference to FIGS. 1 and 2. FIG. 1 is a top view of the reactor 1. FIG. 2 is a cross-sectional view of FIG. 1 taken along line A-A. In FIGS. 1 and 2, terminals of a coil 10 of the reactor 1 are omitted from illustration.

[0028]The reactor 1 as a molded article is a device for use in a motor control apparatus mounted on a vehicle for controlling a vehicle-driving motor. The reactor 1 includes the coil 10 as a component, and a case 11.

[0029]The coil 10 is a circular-ring shaped component formed by winding a copper wire coated with insulating material on its surface. The case 11 is a columnar member made of aluminum for housing the coil 10. The case 11 is formed with a circular groove 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Magnetism | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com