Foil cartridge and method for producing a foil cartridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

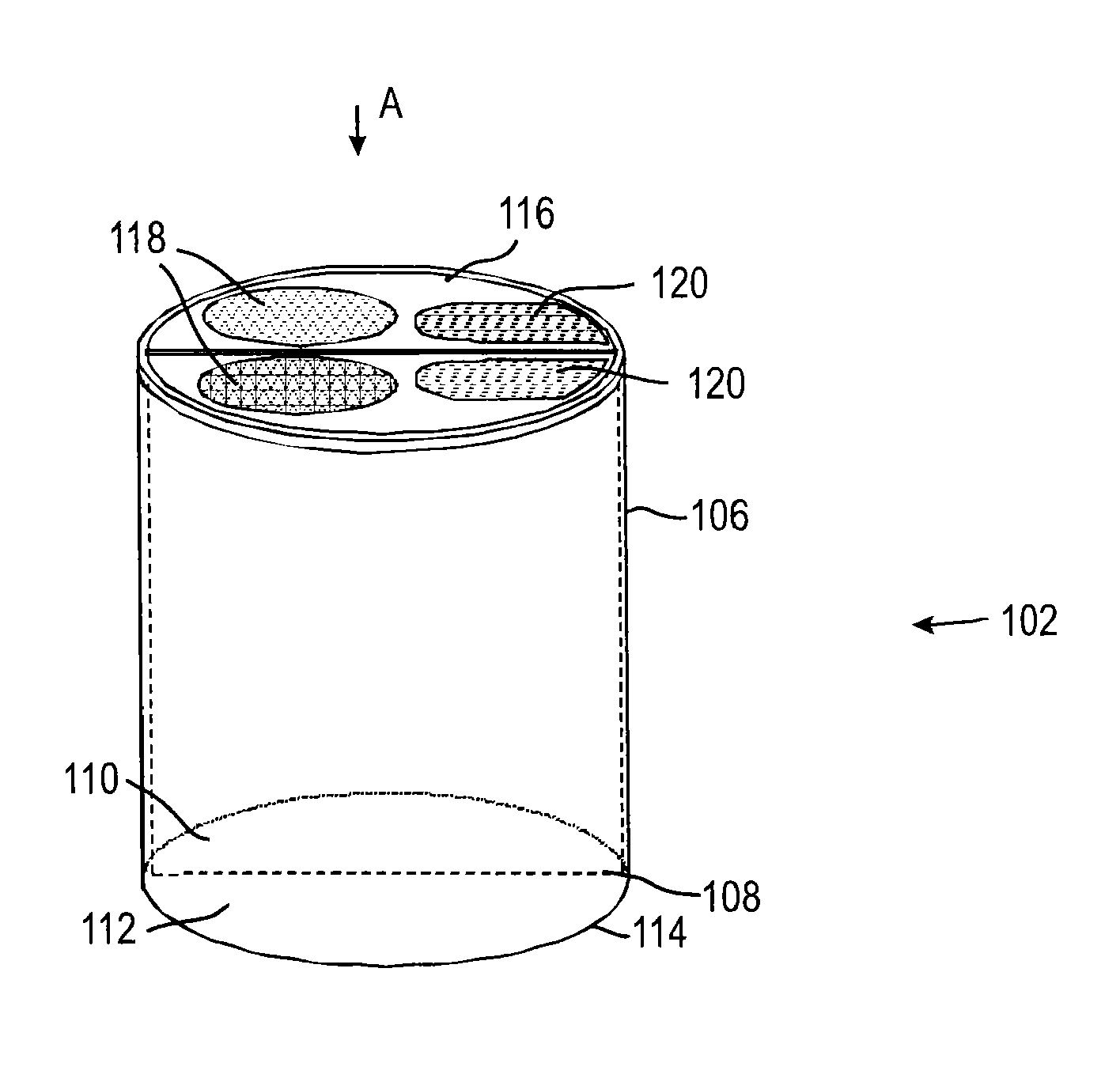

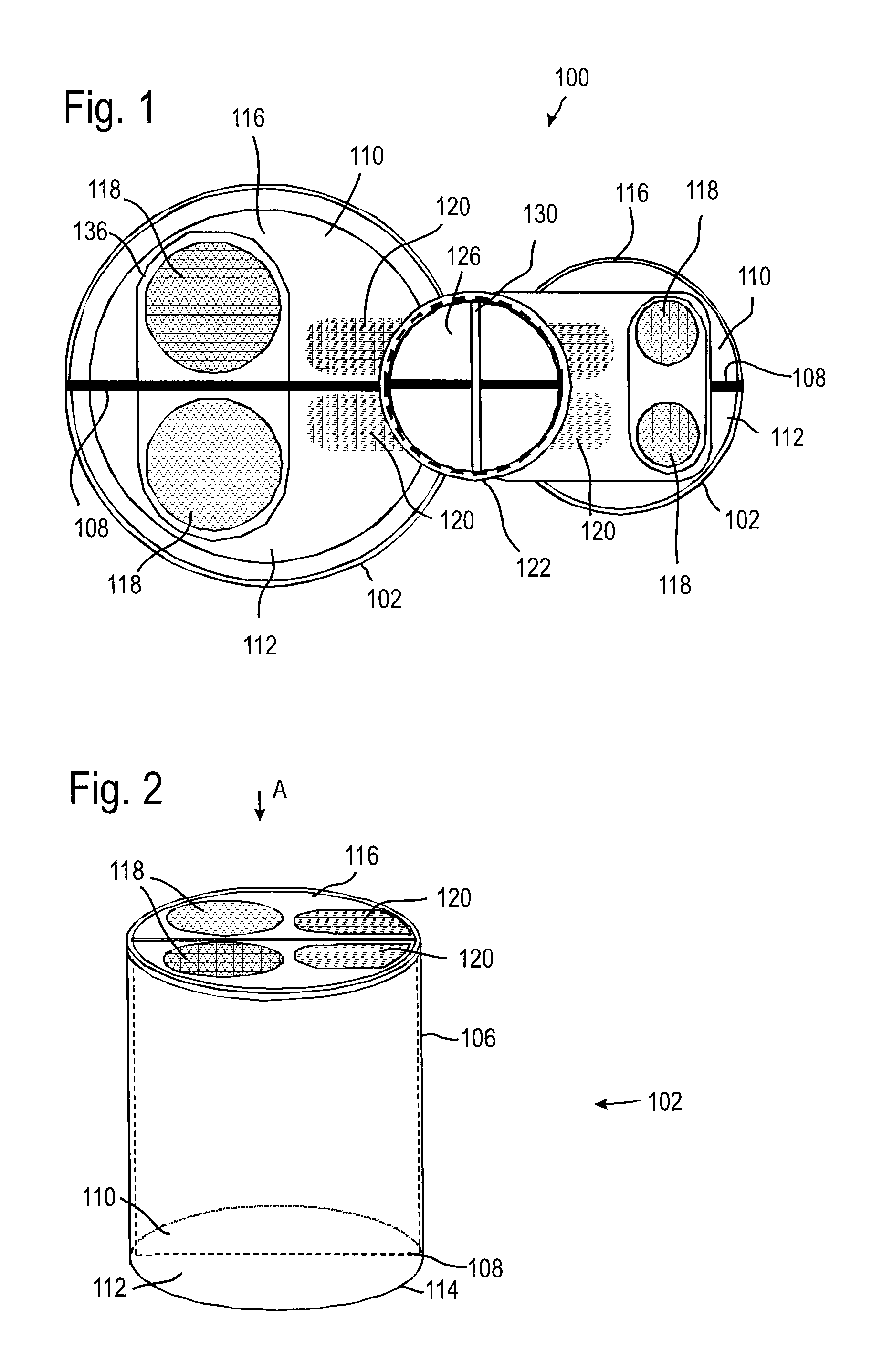

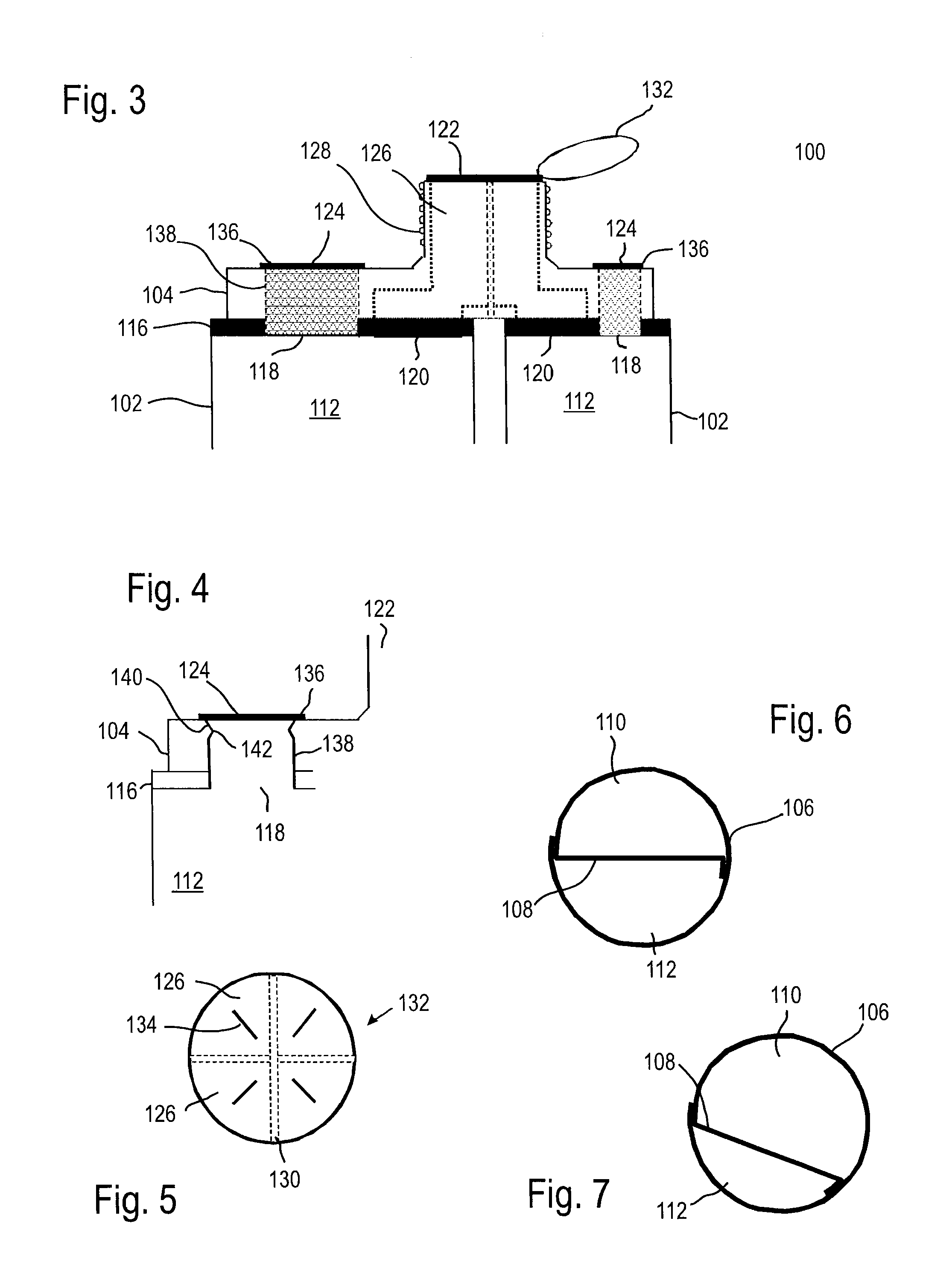

[0064]FIG. 1 shows a foil cartridge 100 in accordance with a first embodiment. The foil cartridge 100 in this case includes two foil reservoirs 102 as well as a head section 104 (see FIG. 3). The head section 104 is connected on an upper axial end to each of the two foil reservoirs 102 that are arranged next to each other.

[0065]One of the foil reservoirs 102 is depicted in greater detail in FIG. 2. A first, outer foil tube 106 is subdivided by a partition 108 (see FIGS. 6 and 7) into two parallel chambers 110, 112 that are separated from each other in the axial direction A. As FIGS. 6 and 7 show, the two chambers 110, 112 may be configured to be the same size or different sizes, which is achieved by the arrangement of the partition 108. Instead of a single partition 108, several partitions 108 could also be provided, which may extend in any desired manner through the cross-section of the foil tube 106.

[0066]The foil tube 106 and the partition 108 in FIGS. 6 and 7 are fabricated of a...

Example

[0091]A second embodiment of a foil cartridge 200 is depicted in FIGS. 8 to 12.

[0092]The reference numbers already used are retained for components that are identical to those of the first embodiment.

[0093]In this case, the separate chambers 110, 112 and 113 are realized by a second foil tube 206 being inserted into the first foil tube 106. In addition, as in the first embodiment, another partition 108 is provided here, which is located between the wall of the first foil tube 106 and that of the second foil tube 206 so that three chambers are formed overall. It would also be possible to provide several second foil tubes 206 or to further subdivide these with partitions.

[0094]As in the first embodiment, each of the chambers 110, 112, 113 is assigned a first opening 118 in the cover 216.

[0095]This arrangement applies to both foil reservoirs 202 (see FIG. 8).

[0096]In contrast to the first embodiment, in this case separate discharge openings are not provided. Correspondingly, the channe...

Example

[0100]FIGS. 13 to 16 show a third embodiment of a foil cartridge 300.

[0101]In contrast to the embodiments described so far, in this case first the foil reservoir 302 is filled before the head section 304 is fastened on the cover 316. The configuration and division of the two foil reservoirs 302 corresponds essentially to that of the first embodiment.

[0102]The head section 304 does not have any further openings besides the outlet opening 122. When the foil cartridge 300 is produced, first the foil reservoir 302 is fabricated. This is filled through the first openings 118, wherein the edge of the openings 118 may be configured in a manner similar to the above-described edge of the opening 124 with a conical taper and a sealing lip (see FIG. 20). After the chambers 110, 112 have been completely filled, the first openings 118 are sealed with closures 340. The closures 340 in this case are configured in the form of a foil having a weakened zone 342, as depicted schematically in FIG. 15. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com